- Product Details

- {{item.text}}

Quick Details

-

Weight:

-

According to the model

-

Size:

-

According to the model

-

Power:

-

According to the model

-

Weight (KG):

-

500 kg

Quick Details

-

Place of Origin:

-

Jiangsu, China

-

Brand Name:

-

QBEP

-

Material:

-

wooden box

-

Weight:

-

According to the model

-

Size:

-

According to the model

-

Power:

-

According to the model

-

Weight (KG):

-

500 kg

Product Description

Screw press sludge Dewatering Machine for Sludge Dewatering Application, is a new type of dewatering equipment, is widely used to dewater sludge n the following industries including chemical, paper-making, pharmacy, leather and etc. This New Generation Sludge Dewatering Machine for Sludge Dewatering Application can run automatically for 24 hours without looking compared to traditional types.

1. Jam Resistance

Low volume of flush water required so as to save the water cost and lower the internal circulation burden caused by the flush

water.

2. Less Covering Space

Electric control panel, flocculation Mixing tank and the dewatering body are integrated as one. So as to save the covering

space which makes the installing much easier.

3. Better Working Environment

This equipment adopts closed operation mode. It treats the sludge stably and in time. The advantage of reducing the smell

on spot provides a better working environment for the workers.

4. Easy to Operate, Easy to Maintain

Realize automatic operation for 24hours so as to release the operation staff from heavy labor. And the design is convenient for

daily maintenance.

5. Cost Saving

The screw shaft operates in low speed which consumes little power. Vibration or noise are both hardly existed on spot.

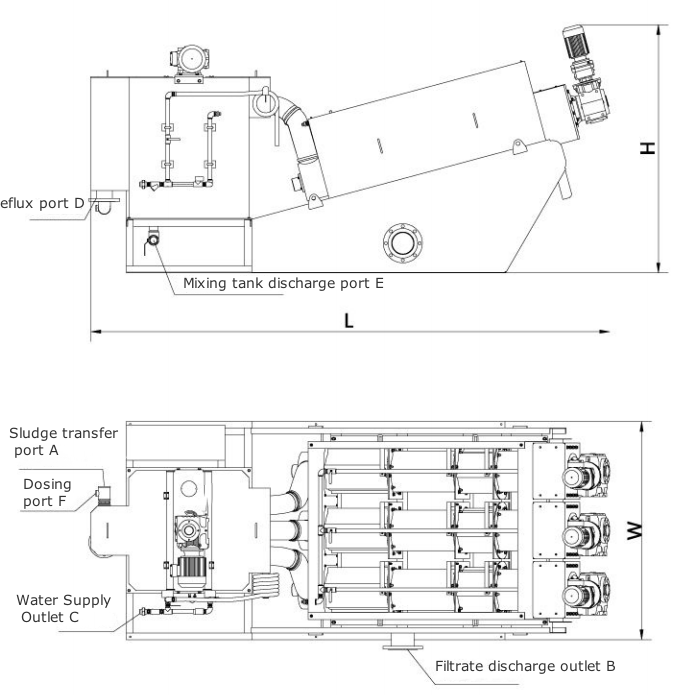

Product Structure

Products Details

Parts of machine

Screw Body

Mainly composed of fixed annular plates and moveable annular plates.

Adopting Wearable material to keep the service life longer. Thickening and dewatering of the sludge can be finished in one canister.

Mixing Reducer

Using first-class reducers, Nord or SEW are optional due to your actual needs.

To ensure the sludge and polymer fully mixed.

Excellent performance to keep the long lifespan.

Liquid level adjusting device is assembled to adjust sludge inletting amount.

Screw Reducer

Using first-class reducers, Nord or SEW are optional due to your actual needs.

Power source of the equipment.

Superior performance with protection grade of IPSS and insulation grade of F.

Frequency conversion starting and speed control to avoid the impact of the load.

Electric Control Panel

Frequency converting controls dewatering body.

Controls polymer mixing device.

Realize the switch of automatic operation and manual operation.

Working principle

and so on, so that we can advise you the most suitable model.

The replacement time of wearing parts is an approximate value. In actual operation, the type of sludge, the treatment method, the operating adjustment condition and the daily operating time will affect the replacement cycle of wearing parts. (Wear parts replacement cycle is calculated based on 365d/y, 16h/d operation time)

Application in various industry

Packing & Delivery

Hot Searches