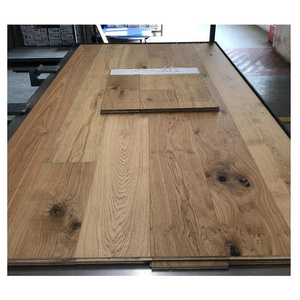

Products:Oak engineered wood flooring

Dimension:15/4X220X2200 mm

(5 5/8 '' 4 mm X8 3/5 '' X 80 3/5'')

Dimension:15/4X220X2200 mm

(5 5/8 '' 4 mm X8 3/5 '' X 80 3/5'')

Pcs/Sqm : 4 pcs/ctn ;1.936 sqm/ctn

G.W.(kg/ctn) :20 KGS

Ctns/PLT:50-66 ctns/pallet ,12 pallets Dimension of PLT : 1230X1930mm;1030x1930mm

G.W.(kg/ctn) :20 KGS

Ctns/PLT:50-66 ctns/pallet ,12 pallets Dimension of PLT : 1230X1930mm;1030x1930mm

Ctns : 770 ctns/container

TAL SQM:1491 sqm/container