- Product Details

- {{item.text}}

Quick Details

-

Brand Name:

-

Shelok

-

Model Number:

-

SLKUHZ10

-

range (mm):

-

300 ~ 19000

-

medium viscosity:

-

≤ 0.02Pa.S

-

working temperature ℃:

-

-180 ~ 350

-

pressure levels (MPa):

-

≤ 32

-

measurement accuracy (mm):

-

≤ ± 10

-

Installation:

-

Side-mounted, roof-mounted, bottom-mounted

-

Protection:

-

IP65

-

transmission:

-

4 ~ 20mA or switch

-

name:

-

4-20mA water tank magnetic float level sensor indicator

Quick Details

-

Grade:

-

Industrial

-

Warranty:

-

1 years

-

Place of Origin:

-

Shaanxi, China

-

Brand Name:

-

Shelok

-

Model Number:

-

SLKUHZ10

-

range (mm):

-

300 ~ 19000

-

medium viscosity:

-

≤ 0.02Pa.S

-

working temperature ℃:

-

-180 ~ 350

-

pressure levels (MPa):

-

≤ 32

-

measurement accuracy (mm):

-

≤ ± 10

-

Installation:

-

Side-mounted, roof-mounted, bottom-mounted

-

Protection:

-

IP65

-

transmission:

-

4 ~ 20mA or switch

-

name:

-

4-20mA water tank magnetic float level sensor indicator

4-20mA water tank magnetic float level sensor indicator

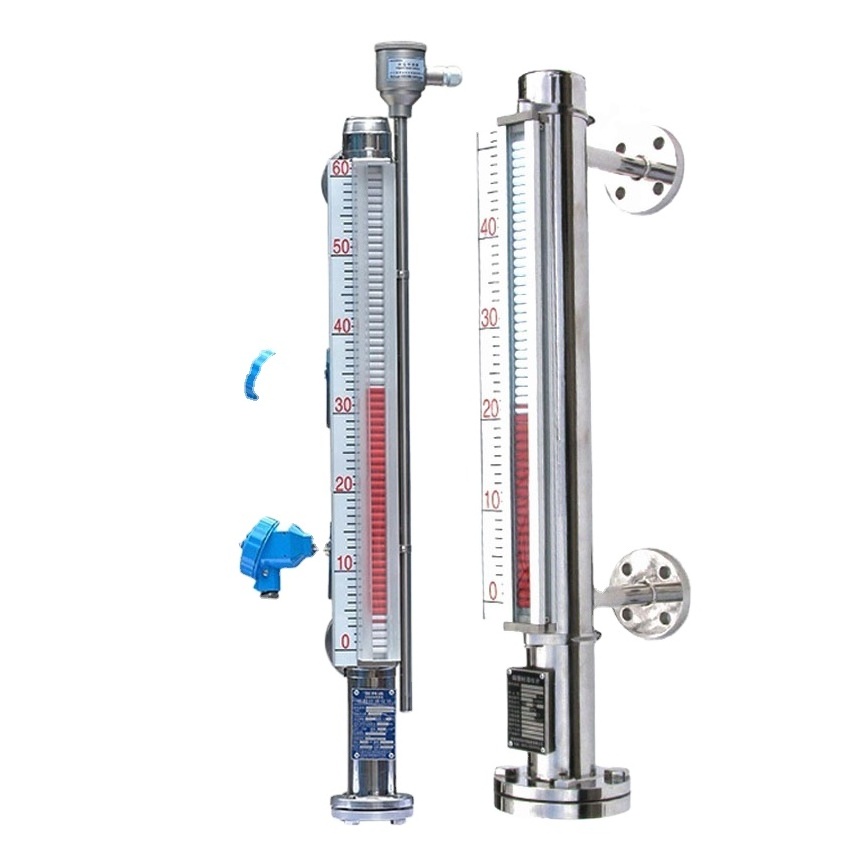

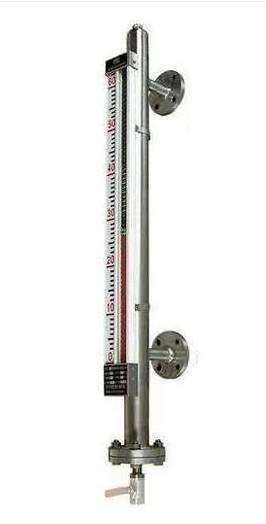

Description water tank magnetic float level indicator

Fuel magnetic level switch indicator introducing and absorbing domestic and foreign products, and to digest, absorb, improve the original magnetic level gauge standards promulgated by the Ministry of Chemical Industry HG/T21584 -95 developed products. Water Tank Magnetic float level gauge Can be used in a variety of media level measurement towers, tanks, tank, spherical vessels and boilers and other equipment. The magnetic level gauge series can achieve high sealed, leak-proof and adaptation level measurement under high pressure, high temperature, corrosive conditions.The entire process of measuring non-blind, eye-catching display, intuitive readings. In particular site instruction part, because no direct contact with the liquid medium, so the high temperature, high pressure, high viscosity, toxic, harmful, corrosive media, can show its superiority. Therefore, Water Tank Magnetic float level gauge is more than the traditional glass, plate level gauge with higher reliability, security, advanced,practical.

Detailed Image water tank magnetic float level sensor

Specification Fuel magnetic float level switch indicator

| range (mm) | 300 ~ 19000 |

| medium density (g/cm3) | ≥ 0.45 |

| medium viscosity: | ≤ 0.02Pa.S |

| working temperature ℃: | -180 ~ 350 |

| pressure levels (MPa): | ≤ 32 |

| measurement accuracy (mm): | ≤ ± 10 |

| Installation: | Side-mounted, roof-mounted, bottom-mounted |

| Protection: | IP65 |

| proof grade: | ib Ⅱ CT4 (intrinsically safe), d Ⅱ BT3 (flameproof) |

| transmission: | 4 ~ 20mA or switch |

Features water tank magnetic level indicator

Level gauge the main components (body) in direct contact with the medium are made of stainless steel material or other special materials, indicating that components are not in contact with the media, and therefore containing flammable, explosive, toxic, corrosive media container use the gauge is safe and reliable.

Two-color (white vapor, liquid red) turned columns, flap display, indicating continuous visual eye-catching, no blind spots, in any case will not be a false level.

Less sealing surface, reducing static seal leakage points above 95%, and thus, to overcome the petroleum, chemical industry pressure vessel parts run,run, drip, leak and other weak links than the original plate level gauge.

Simple structure, easy installation and maintenance, large-scale, design pressure, long life, wide range of applications.

Magnetic float level gauge, with a level gauge can replace more than one glass plate liquid level gauge, and the installation extremely easy to use. Meanwhile, the use of plant development level remote transmitter, alarm and automatic control device, can be realized on the lower level alarm and control automation.

Selection water tank magnetic float level indicator

Measuring length

Connection flange standards

Media name and density

Medium temperature

Medium pressure

Installation

Material selection

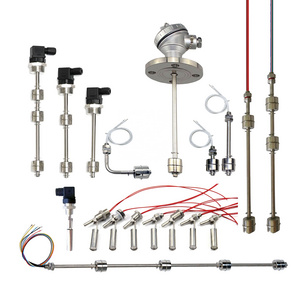

Related products

FAQ

Q:How long will you reply me?

A:We will contact you as soon as possible but within 12 hours

Q: Can I get some samples?

A: Yes, Sample order is available for quality check and market test. But you have to pay the express cost.

Q: How soon can you arrange your production?

A: Once getting your product confirmation and receiving the prepayment, the production will be started immediately.

Q: What's delivery time?

A: It usually takes about 3-5 working days for small order and 10-15 days for big order.

Q:How do you control your quality ?

A: Three inspection steps(of original, production, and finished goods) + good warranty service(1 year free to change a new one without any human damage factors).

Q: What certificates do you have ?

A:ISO9000, CE, Explosion-proof certification, RoHs ready. And before the delivery of goods, quality and safety inspection certification issued by third parts also can be offered.

Q:Could I visit your factory?

A:Very welcome! Fly to Xian Yang air port. It was a big pleasure for us.

Q: What's your warranty terms?

A: We offer 12 months warranty time.

Q:can you provide OEM & Customized service?

A:Yes, OEM and ODM are both available, we have the professional R&D dept which can provide professional solutions for you.