- Product Details

- {{item.text}}

Quick Details

-

Brand Name:

-

TZT

-

Model Number:

-

TZT-gold testing machines electronic

-

Focal Length:

-

1

-

Wavelength Range:

-

0.22mm

-

Product name:

-

XRF RoHS Halogen tester

-

Function:

-

Metal purity analysis

-

Type:

-

Xrf Analyzer

-

Test material:

-

Metal gold silver alloy

-

Measuring range:

-

S to U

-

Accuracy:

-

0.01%

-

Feature:

-

Easy Operation

-

Delivery time:

-

7-15days

-

Warranty:

-

1 Year

-

Application:

-

Pawn shop jewellery manufacture

Quick Details

-

Size:

-

650*450*350mm

-

Weight:

-

38kg

-

Place of Origin:

-

Guangdong, China

-

Brand Name:

-

TZT

-

Model Number:

-

TZT-gold testing machines electronic

-

Focal Length:

-

1

-

Wavelength Range:

-

0.22mm

-

Product name:

-

XRF RoHS Halogen tester

-

Function:

-

Metal purity analysis

-

Type:

-

Xrf Analyzer

-

Test material:

-

Metal gold silver alloy

-

Measuring range:

-

S to U

-

Accuracy:

-

0.01%

-

Feature:

-

Easy Operation

-

Delivery time:

-

7-15days

-

Warranty:

-

1 Year

-

Application:

-

Pawn shop jewellery manufacture

| Name: | Gold Testing Machines Electronic Exf9600 Xrf Machine Spectro Lab With Price Fischer Black Stone -Toilet | |||

| Testable elements: |

Elements from sulfur to uranium

RoHS restricted harmful elements Pb/Hg/Cd/Cr/Br HF limited halogen harmful element Br/Cl The eight heavy metals in En71-3 are lead (Pb)/arsenic (As)/antimony (Sb)/barium (Ba)/cadmium (Cb)/chromium (Cr)/mercury (Hg)/selenium (Se) |

|||

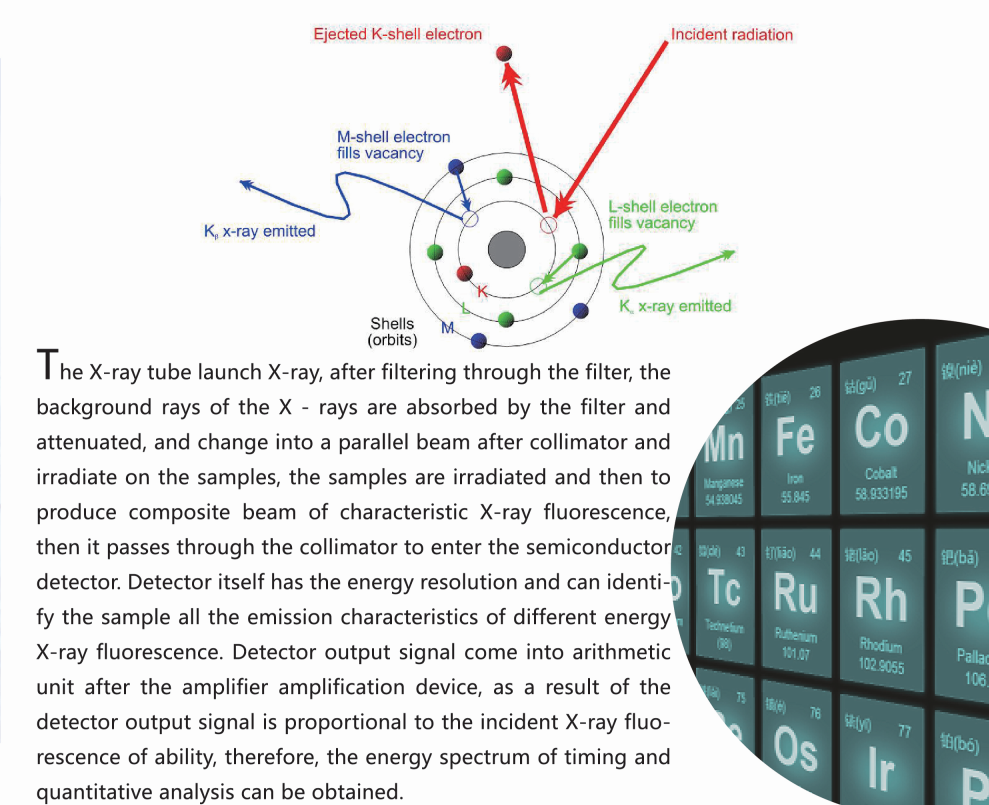

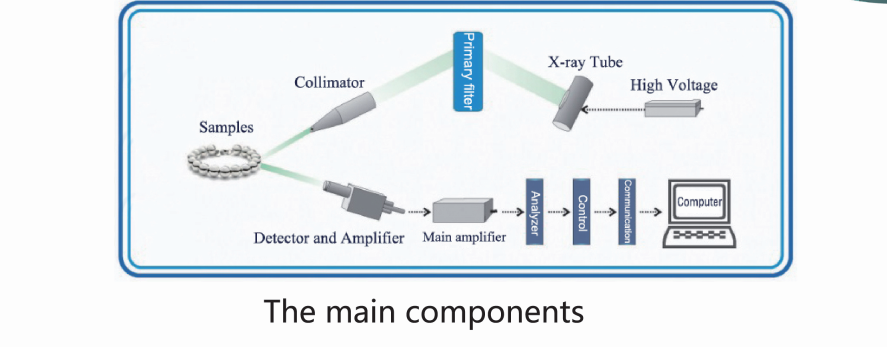

| Equipment principles: | X fluorescence energy dispersion | Collimator: |

Light spot : φ 1 mm ,3mm,5 mm ( automatic selection by software) |

|

|

Lowest limit of detection |

Content analysis:0.01%-99.99% RoHS:Cd/Cr/Hg/Br≤2ppm Pb≤5ppm Cl≤60ppm |

Voltage/power: | 100-220v/128w | |

| Detector: | Si-Pin probe(Made in USA) 145±5eV |

Material of X-ray tube window |

Metal Be-window |

|

|

Sample forms/range |

Solids,liquids,powders; |

Operating systerm: | Windown 7 | |

| Work enviroment: | - 11 ~ 46 °C | Advantages: | excellent cooling system | |

| Battery support:: | no | Intelligence: | automatic protection | |

| Label/normal/thermal printer: | support | Dimension of sample cavity | 28*28*20cm | |

|

High Voltage source |

0-50kev,0-2mA |

Machine net weight: |

36kg | |

|

Built-in computer: |

yes | Machine size: | 650×450×350mm | |

Working pricinple:

Energy dispersive X-ray fluorescence spectrometer (XRF) is a physical element analysis method. In recent years, XRF is mainly used as a fast testing method has played a great role in electronics, electrical appliances, jewelry, toys, food, building materials, metallurgy, geology and mining, plastics, petroleum, chemical industry, medicine and other industries.

XRF has the advantages of rapid, nondestructive, simultaneous analysis of multiple elements and low cost.

XRF W7 belongs to high-end integrated model, triple ray protection system, humanized operation interface, comprehensive application of experience coefficient method and basic parameter method v8.0 analysis software. In other words, it can detect Pb, CD, Hg, Br in PBDE and PBB, Cr in hexavalent chromium and Cl and Br elements in Halogen-free directive. It can fully meet the RoHS / WEEE / halogen-free control requirements. The well-designed open working curve function is especially suitable for multi materials factory process control. Moreover It has superior test performance in metal analysis, such as copper alloy, ferroalloy, aluminum alloy, test stability and accuracy in the industry are relatively excellent.

XRF W7 is widely used to test electroplating coatings, such as iron zinc plating, iron chromium plating, copper nickel plating, gold plating, copper tin plating, etc.

In addition, XRF is widely used in field analysis and process control analysis, such as waste metal recycling, soil field detection, online material inspection, etc

1.Highly integrated industrial motherboard and multi-piont hand tough,make it stable and fashion

2.Used a real 5 million pixel camera, the sample can be observed clearly and the location is accurate

3.The detection limit of trace elements is improved by using the two intensity extraction algorithm of unique elements

4.The sound reminding function to facilitate the multitasking of the operator

5.Used water lamp control module, make the operator more easy to understand the state of the instrument

6.The software integrates multiple RoHS limit standards in the same mode.

7.The same software integrated component analysis and coating thickness analysis.

Our Advantages:

10.Integrates data statistics to facilitate quality departments to screen statistics of suppliers, material names, components, and test conditions during different periods of time.

11.provides an open work curve calibration function, which can be used to determine the best method and control scheme for the detection of harmful substances for the users.

12.Automatic inspection software and fault judgment function to ensure that the instrument is always running in the best working state and is eliminated in time when abnormal condition occurs.

13.analysis data backup/ restore function, avoid the loss caused by misoperation or other reasons, and ensure the security of data and system files.

14.Customize the test report output format (Excel, PDF and list, etc.) according to the user's needs, and meet the various statistical requirements of the factory.

15.It has the core hardware real-time temperature monitoring function.Through the heat source analysis system and the real-time control, the heat of hardware is discharged in time. In order to reduce the influence of temperature change on detector .

16.Support large sample test function,and have process guidance design.

Quality Control System:

- Every parts should be put in temperature and humidity test chamber for 72 hours before assembling.

- Every machine need to do aging testing for another 72 before shipping

3.Every machine is with its unique series number .Engineer will be responsed for the quality of the machine he made.

1: The whole machine is guaranteed for 12 months; provide technical service support for life.

2: During the warranty period, if the product has quality problems under normal use, after verification by Party B, it will provide free maintenance services and will not charge any fees to Party A; if the quality problem is not the instrument itself, it is due to user's human factors. Party B needs Charge the cost of parts repair or replacement.

3: Response time: Within 24 hours.Any problem,our professional team can check for you remotely.