- Product Details

- {{item.text}}

Quick Details

-

Brand Name:

-

QY

-

Product name:

-

Insulator alumina Ceramic part

-

Electrical Insulation:

-

Excellent

-

Density:

-

3.65 - 3.90 g/cm3

-

Max. Working Temp:

-

1,500 - 1,800 °C

-

Color:

-

white and ivory

-

Certificate:

-

ISO9001-2008/CE

-

Thermal Shock Resistance:

-

180 - 220 T(°C)

-

Compressive Strength:

-

2,000 - 2,500 Mpa

-

Flexural Strength:

-

280 - 300 Mpa

Quick Details

-

Material:

-

Alumina Ceramic

-

Place of Origin:

-

Hunan, China

-

Model Number:

-

QY23083103

-

Brand Name:

-

QY

-

Product name:

-

Insulator alumina Ceramic part

-

Electrical Insulation:

-

Excellent

-

Density:

-

3.65 - 3.90 g/cm3

-

Max. Working Temp:

-

1,500 - 1,800 °C

-

Color:

-

white and ivory

-

Certificate:

-

ISO9001-2008/CE

-

Thermal Shock Resistance:

-

180 - 220 T(°C)

-

Compressive Strength:

-

2,000 - 2,500 Mpa

-

Flexural Strength:

-

280 - 300 Mpa

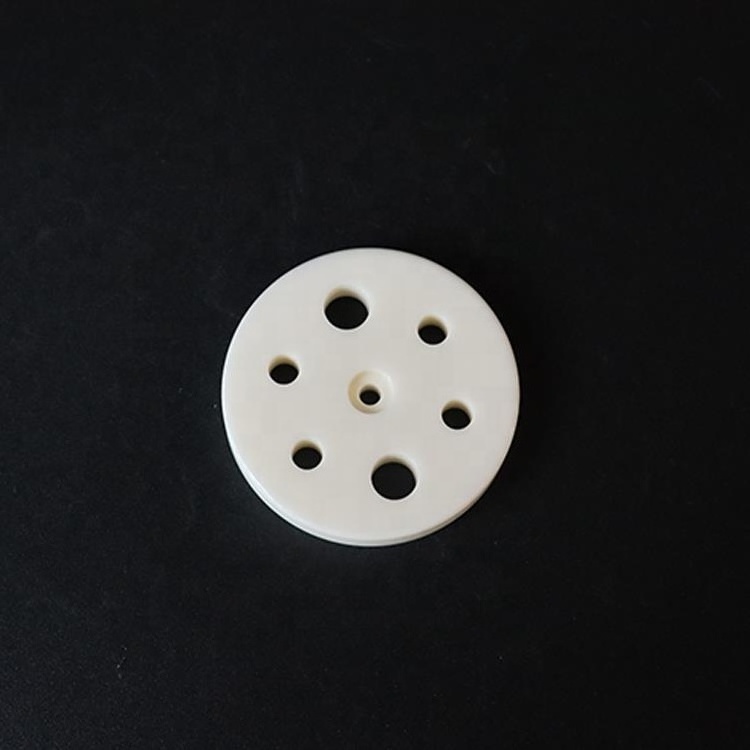

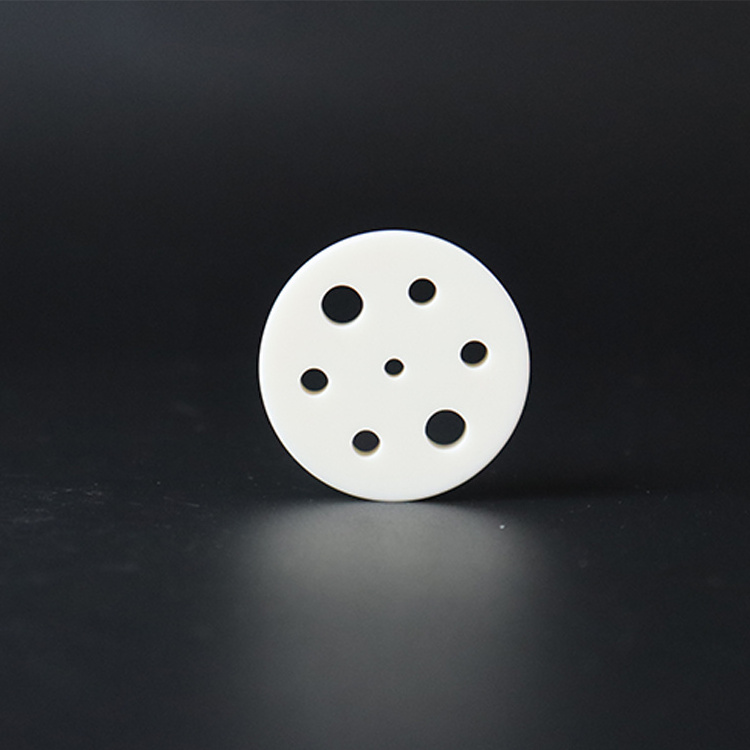

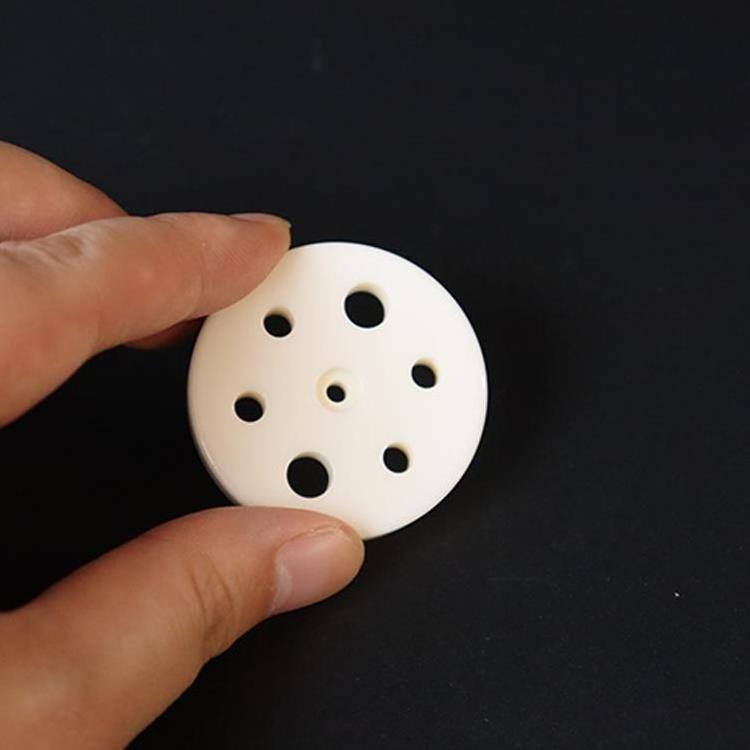

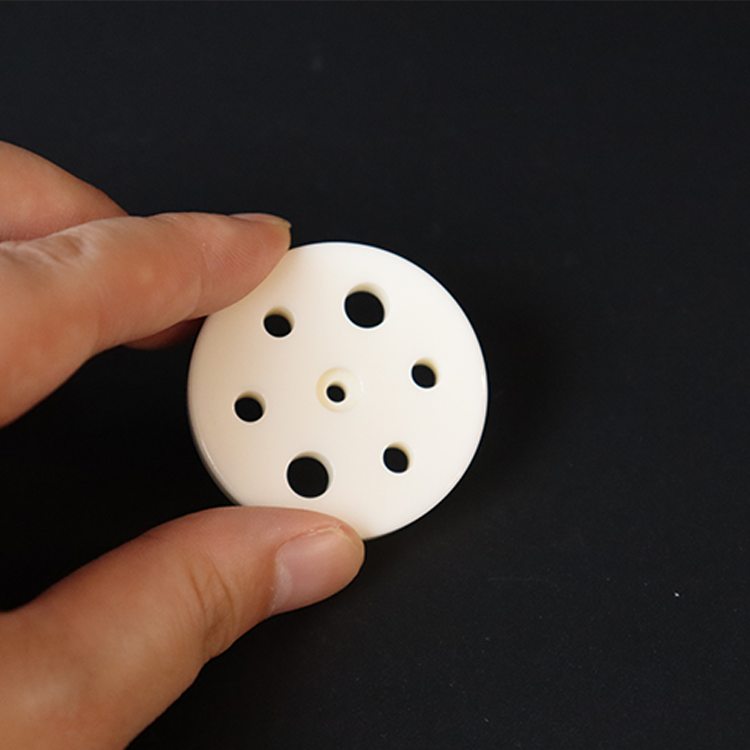

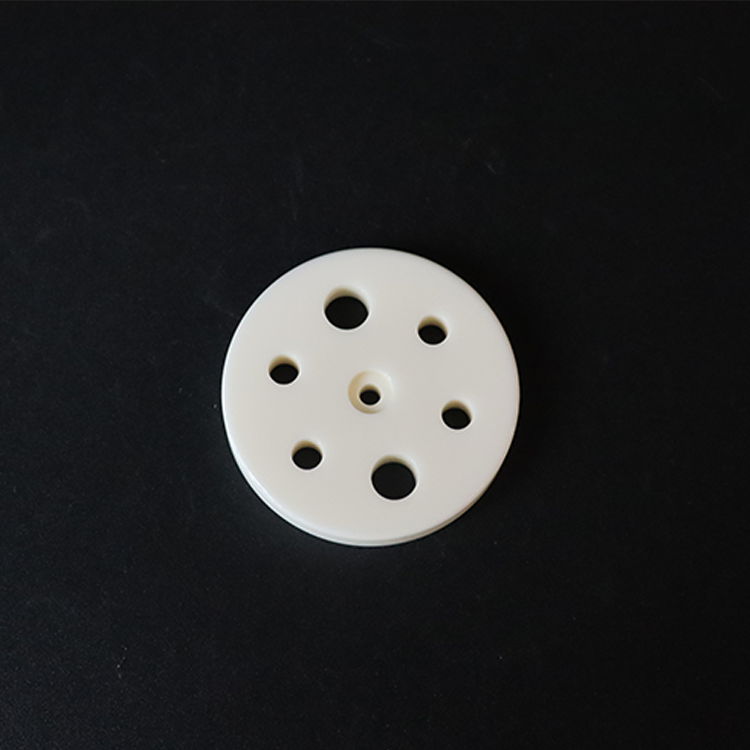

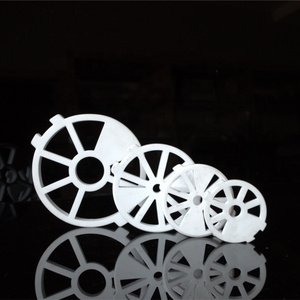

ODM OEM 15 mm Al2o3 Gasket Spacer Alumina Ceramic Parts alumina ceramic disc for tap

Alumina Ceramic Manufacturing for electric and electronic device components:

1. 95% alumina Al2O3 is used to produce ceramic parts for electrical equipment, using imported raw materials, formed by dry pressing or hot pressing, with high mechanical strength, high hardness, wear resistance, high temperature resistance, corrosion resistance, high electrical insulation with low dielectric loss, etc.

2. Can be extended to do metallization, brazing and other seals processes on complex ceramic bodies.

3. Customized products, can be completed according to customer's drawing requirements.

4. Complied with RoHs, ISO9001 quality standards.

5. Products applied for Medeical, Aerospace, Military, Electrict Power, Solar, Power, Semiconductors, Communications Equipment, Machining, New

Energy ect.

| Test item | alumina | |||

| index | unit | AL997 | AL99 | AL95 |

| Principal component content | N/A | 99.70% | 99% | 95% |

| Color | N/A | ivory white | ivory yellow | White |

| Gas permeability | N/A | airtight | airtight | airtight |

| density | g/cm3 | 3.9 | 3.8 | 3.7 |

| hardness | Moh's hardness | 9 | 9 | 8.8 |

| Water Absorption | N/A | ≤0.2 | ≤0.2 | ≤0.2 |

| Bending strength (20°C) | Mpa | 375 | 340 | 304 |

| Compressive Strength (20°C) | Mpa | 2300 | 2210 | 1910 |

| Coefficient of thermal expansion (25°C to 800° C) | 10X6/° C | 7.6 | 7.6 | 7.6 |

| Insulation strength (5mm thickness) | AC-kv/mm | 10 | 10 | 10 |

| Dielectric loss 25°C lMHz | N/A | v0.0001 | 0.0006 | 0.0004 |

| dielectric constant 25°C MHz | N/A | 9.8 | 9.5 | 9.2 |

| Volume resistivity (20°C) (300°C) (500 °C) | Ω.cm3 | >1014 | >1014 | >1014 |

| 2X1012 | 4X10" | 2X10" | ||

| N/A | N/A | N/A | ||

| Long-term service temperature | ℃ | 1700 | 1600 | 1400 |

| Thermal conductivity (25° C) | W/m/K | 35 | 34 | 20 |

Material Properties

- Excellent electrical insulation properties

- High hardness and mechanical strength

- Wear and abrasion resistant

- High thermal conductivity and thermal shock resistance

- Low density

- Resistant to strong acid and alkali attack at high temperatures

- Transparent to microwave radio frequencies

- High compressive and dielectric strength

- Very specific thermal conductive and thermal expansion rates

1. Excellent electrical insulation.

2.Medium to ultra high mechanical strength.

3.Very high compressive High hardness.

4.Medium thermal conductivity.

5.High corrosion and wear resistance.

6.Good grinding properties;Low density.

7.The operating temperature is 1000 to 1500°C without mechanical load;Biological inertia