- Product Details

- {{item.text}}

Quick Details

-

Main Material:

-

Bitumen ,Polyester Felt

-

Thickness:

-

3mm-5mm

-

Ceiling Tile Type:

-

Polyester Felt , or glassfiber

-

Surface Treatment:

-

Film Coated

-

Function:

-

Waterproof

-

Certification:

-

ISO ,CE

-

Usage:

-

Outdoor

-

Length:

-

10m/roll

Quick Details

-

Place of Origin:

-

Shandong, China

-

Type:

-

Waterproof Roll Material

-

Product Name:

-

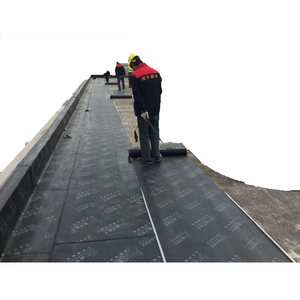

Torch down roofing bituminous waterproof membrane

-

Main Material:

-

Bitumen ,Polyester Felt

-

Thickness:

-

3mm-5mm

-

Ceiling Tile Type:

-

Polyester Felt , or glassfiber

-

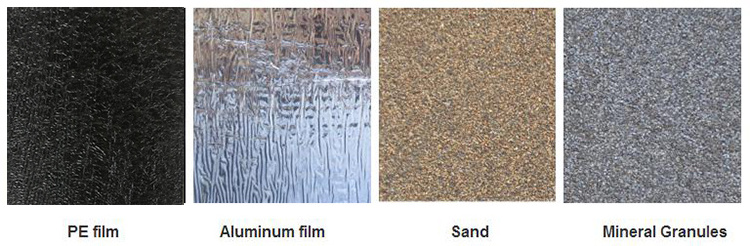

Surface Treatment:

-

Film Coated

-

Function:

-

Waterproof

-

Certification:

-

ISO ,CE

-

Usage:

-

Outdoor

-

Length:

-

10m/roll

Torch down roofing bituminous waterproof membrane

| Modified Bituminous Roofing Torch Waterproof Membrane | |

|

Polyethylene film / Aluminum foil / Fine sand / Mineral grain material |

|

Specification can be customized as requirement.

1. Excellent resistance to high temperature

2. High tensile strength and elongation

3. Resistance to root puncture , tear , corrosion and weathering

4. Easy to apply , long service life

GB18242-2008 ---SBS

| No. | Item | Index | |||||

| Ι | ΙΙ | ||||||

| PY | G | PY | G | PYG | |||

| 1 | Solid content (g/m 2 ) ≥ | 3mm | 2100 | - | |||

| 4mm | 2900 | - | |||||

| 5mm | 3500 | ||||||

| Test phenomenon | - | Non-ignitable | - | Non-ignitable | - | ||

| 2 | Heat resistance | °C | 90 | 105 | |||

| ≤mm | 2 | ||||||

| Test phenomenon | no flow or drippage | ||||||

| 3 | Flexibility at low temperature °C | -20 | -25 | ||||

| 4 | Water tightness 30min | 0.3Mpa | 0.2Mpa | 0.3Mpa | |||

| 5 | Tensile strength | Tension of maximum peak (N/50MM) ≥ | 500 | 350 | 800 | 500 | 900 |

| Tension of secondary maximum peak (N/50MM) ≥ | - | - | - | - | 800 | ||

| Test phenomenon | No cracks or separate | ||||||

| 6 | Elongation | Elongation at maximum peak (%) ≥ | 30 | - | 40 | - | - |

| Elongation at secondary maximum peak (%) ≥ | - | - | - | - | 15 | ||

| 7 | Mass increased after immersion (%)≤ | PE S | 1.0 | ||||

| M | 2.0 | ||||||

| 8 | Thermal aging | Conservation rate of tensile strength (%) ≥ | 90 | ||||

| Conservation rate of elongation (%) ≥ | 80 | ||||||

| Flexibility at low temperature ℃ | -15 no crack | -20 No crack | |||||

| Dimensional stability %≤ | 0.7 | - | 0.7 | - | 0.3 | ||

| Mass loss (%) ≤ | 1.0 | ||||||

| 9 | Oil permeability | the number of sheet | 2.0 | ||||

| 10 | Peel strength of joints N/mm ≤ | 1.5 | |||||

| 11 | Tear strength/ nail shank a N ≥ | - | 300 | ||||

| 12 | Adhesion of mineral granules b ≤ | 2.0 | |||||

| 13 | The thickness of Bitumen coating layer on the membrane bottom c mm ≥ | 1.0 | |||||

| 14 | Artificial weather aging | Appearance | No sliding, no flowing, no dripping | ||||

| Conservation rate of tension % ≥ | 80 | ||||||

| Flexibility at low temperature ℃ | -15 | -20 | |||||

| no cracks | |||||||