- Product Details

- {{item.text}}

Quick Details

-

Place of Origin:

-

Jiangsu, China

-

Brand Name:

-

Vichen

-

Voltage:

-

220V

-

Dimension(L*W*H):

-

Customer Request

-

Name:

-

pet woven mesh belt

-

Temperature resistance:

-

260F

-

Mesh size:

-

1x1mm,2x2mm,1x2mm,4x4mm,6x6mm,10x10mm

-

sides:

-

Reinforced with ptfe fabric or film

-

Joint:

-

bull nose or metal claps

-

Application:

-

Textile drying,screen printing,circuit drying,UV dryers

-

Color:

-

Birge, black

-

Feature:

-

Non-sticky, high temperature resistance,Drying

-

Belt Width:

-

Max.4M

-

Length:

-

Customized

-

Certification:

-

ISO9001:2008

Quick Details

-

Power:

-

0

-

Warranty:

-

Unavailable

-

Width or Diameter:

-

500mm

-

Place of Origin:

-

Jiangsu, China

-

Brand Name:

-

Vichen

-

Voltage:

-

220V

-

Dimension(L*W*H):

-

Customer Request

-

Name:

-

pet woven mesh belt

-

Temperature resistance:

-

260F

-

Mesh size:

-

1x1mm,2x2mm,1x2mm,4x4mm,6x6mm,10x10mm

-

sides:

-

Reinforced with ptfe fabric or film

-

Joint:

-

bull nose or metal claps

-

Application:

-

Textile drying,screen printing,circuit drying,UV dryers

-

Color:

-

Birge, black

-

Feature:

-

Non-sticky, high temperature resistance,Drying

-

Belt Width:

-

Max.4M

-

Length:

-

Customized

-

Certification:

-

ISO9001:2008

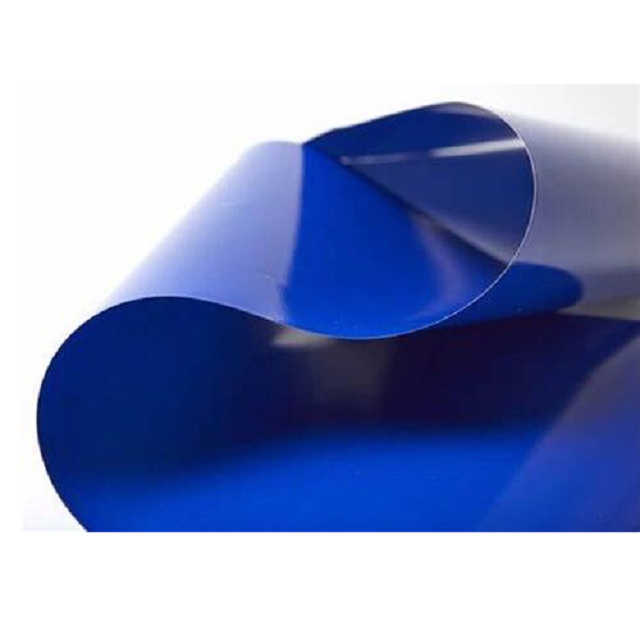

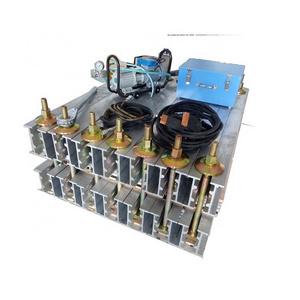

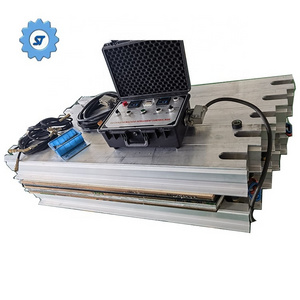

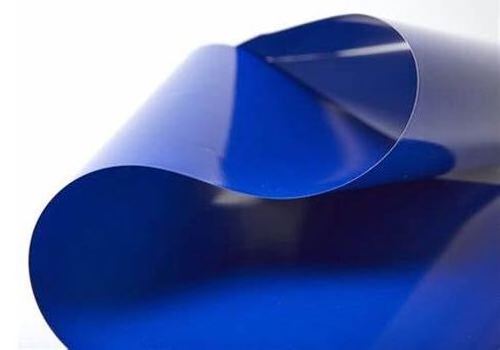

Tortilla Press Belt

PTFE seamless/seam fusing machine belts are are specifically engineered with the mechanical strength needed for the fusing and laminating industries. Its non-stick surface, thermal transfer and high temperature resistance characteristics ensure the flow of woven and non-woven materials through the fusing and lamination process.

|

Tortilla Press Belt

|

|

|

|

|

|

|

|

|

|

|||||||||

|

Standard Thickness: 0.35~0.40mm

|

|

|

|

|

|

|

|

|

|

|||||||||

|

Width: 20~1500mm

|

|

|

|

|

|

|

|

|

|

|||||||||

|

Perimeter: (mm)

|

|

|

|

|

|

|

|

|

|

|||||||||

|

1360

|

1380

|

1440

|

1470

|

1510

|

1520

|

1530

|

1540

|

1550

|

1560

|

|||||||||

|

1580

|

1600

|

1640

|

1660

|

1680

|

1730

|

1740

|

1780

|

1820

|

1830

|

|||||||||

|

1840

|

1850

|

1870

|

1880

|

1950

|

2000

|

2040

|

2100

|

2230

|

2240

|

|||||||||

|

2250

|

2310

|

2320

|

2420

|

2440

|

2450

|

2500

|

2600

|

2630

|

2750

|

|||||||||

|

2800

|

2820

|

2850

|

2880

|

2900

|

3050

|

3080

|

3090

|

3200

|

3450

|

|||||||||

|

3540

|

3590

|

3820

|

3850

|

3890

|

3900

|

3920

|

3930

|

4200

|

4270

|

|||||||||

|

5100

|

5270

|

5400

|

5640

|

5800

|

6000

|

6440

|

6700

|

|

|

|||||||||

DESCRIPTION

PTFE seamless/seam fusing machine belts are are specifically engineered with the mechanical strength needed for the fusing and laminating industries. Its non-stick surface, thermal transfer and high temperature resistance characteristics ensure the flow of woven and non-woven materials through the fusing and lamination process. These belts are for fusing machines,such as Oshima,Kannegiesser, Meyer, Macpi,and many others.

Ours currently provide the following three types of belts:

1.Seamless Fusing Belts

means fusing belt without any joint.It is made from woven fiberglass or Kevlar coated with ptfe resin.The seamless belts have a smooth surface, excellent antistatic effect (black version), long life.It overcomed the shortage of traditional fusing belts with joint.

2.Seam Fusing Belts

means fusing belt with joint.It is the most common fusing belts due to its lower cost.Three joint methods are provided as below:

Overlap Belt Joint

: Overlap joints are a simple and easy joint to use where having an even surface is not critical. This is the most popular seam because it is strong inexpensive and easiest to produce. The disadvantage of the overlap seam is that it is not very smooth and in some applications the seam may mark the material being fused. In addition, because the overlap seam is more than double the thickness of the rest of the belt it is slightly stiffer and suffers from early flex fatigue and very often breaks.

Scarfed Belt Joint

: A scarf joint is similar the overlap but offer a smooth transition for the product to run offering no lip for

products to catch on.This is the smoothest, strongest, most flexible seam available today. It resembles a 30 mm overlap seam but is much smoother and more flexible. There is no almost double thickness, as the mating surfaces are carefully ground to a taper and securely welded.

Angled Belt Joint

: This seam is cut at a slight angle helping the belt to roll easily over the fusing machine rollers, reducing

flex fatigue. The angle of the overlap can be varied, so that the splice does not run over the conveyor pulleys in one line. 45° and 70° are popular.

3.Laminated Fusing Belts also called two ply or double layer fusing belts.This belt use static-resistance varnished cloth inside and tearing-resistance fiberglass cloth outside, 2ply belt has a great improvement on its intensity, long using life, well balanced thickness, excellent deflecting preventing capacity, smooth surface, it’s better for super thin fabric fusing.

Sales Service

* Inquiry and consulting support within 12h.

* Sample lead time 3-7days.

* View our Factory.

After-Sales Service

* Professional cooperative freight forwarding, such as DHL, UPS, TNT, FEDEX.

* The cheapest price and the fastest delivery time.

|

Packaging workshop

|

|

|

|

|

30 professional package workers

|

|

|

Area

|

300 square meters

|

|

|

Advantages

|

2.Non-dust workshop to avoid goods dusty

3.Four packaging lines, greatly reducing packaging time

|

|

|

Packaging

|

|

|

|

Size

|

Depends your goods

|

|

|

Style

|

Export cartons or wooden cartons

|

|

|

Packaging Details

|

|

|