- Product Details

- {{item.text}}

Quick Details

-

After-sales Service Provided:

-

Engineers available to service machinery overseas

-

usage:

-

can machine,can making,can welder

-

After Warranty Service:

-

Online support

-

Certification:

-

CE Certificate

-

Marketing Type:

-

Hot Product 2019

Quick Details

-

Place of Origin:

-

Guangdong, China

-

Brand Name:

-

zhengyi

-

Weight:

-

4600 KG

-

After-sales Service Provided:

-

Engineers available to service machinery overseas

-

usage:

-

can machine,can making,can welder

-

After Warranty Service:

-

Online support

-

Certification:

-

CE Certificate

-

Marketing Type:

-

Hot Product 2019

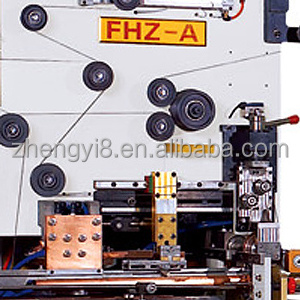

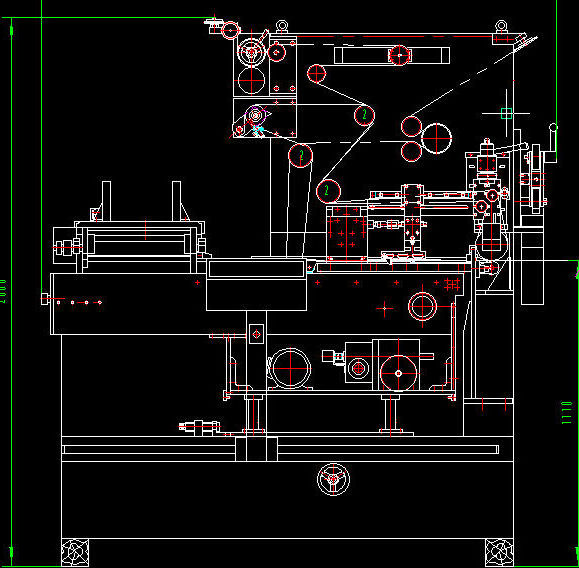

can machine

Detail:

| Model | FHZ-A |

| Applicable can diameter | Φ52-105mm |

| Applicable can height | H70-250mm |

| Production capability | 80-150cans/min |

| Seam welding landing | 0.4mm 0.6mm |

| Linear rate of welding | 6-24m/min |

| Sealing point distance | 0.5-0.9mm |

| Material | Tinplate Ni plate |

| Sheet thickness | 0.16-0.3mm |

| Sheet hardness | T2-DR8 |

| Copper diameter | Φ1.38mm Φ1.5mm |

| Cooling water | 0.4 Mpa 12-18°C 20L/min |

| Compressed air | 0.5 Mpa |

| Volume of compressed air | 800L/min |

| Coating capacity | 6-30m/min |

| Coating manner | by rotaing wheel (Automatic glue-feeding) |

| Coating width | 10-14mm |

| Drying capability | 6-30m/min |

| Drying manner | Drying by electric heating |

| Size of seam welder | 1730×1695×1920mm |

| Sizoof intemal and extemal coating | 2100×650×1300mm |

| Size of drier | 9600×680×1460mm |

| Input power three-phase | AC380V 50Hz |

| Total power of the producing line | 50KVA |

| Total weight of machine set | 4600Kg |

Our major component suppliers:

1. Pneumatic elements are purchased from Japanese “SMC”

2. Hydraulic elements are purchased from Taiwan precision brand

3. Electronic control devices are purchased from “Schneider”, “Omron” and some domestic suppliers

4. Worktable surface is produced by #304 stainless steel gold plated

5. Machine surface paint is purchased from “NAVECO” car paint

Chromeplate device could be assembled specially.

GNWT-Z internal and external seam coating machine uses automatic glue feeding device which avoids the trouble of stoping the machine to add glue. Manual feeding of glue can lead to uneven and total miss coating. GNWT-Z has many advantages over other machines of its kind because it coats the can by rotating the wheel. This also prevents the coating nozzle from blockage. GNWT-Z is indeed economical.

GHG-Z can body heat air drying machine applys reliable mutual-restraint controlling device, so it is easy to operate. Its temperature is controlled by 9-degree heating machine , so the exchange rate of heating is high and temperature can be changed from 250 to 400 continuously.