- Product Details

- {{item.text}}

Quick Details

-

Place of Origin:

-

Netherlands

-

Year:

-

2024

-

Brand Name:

-

FillinMachine

-

Dimension(L*W*H):

-

1250 * 1200 * 1700mm

-

Weight (KG):

-

280

-

Product name:

-

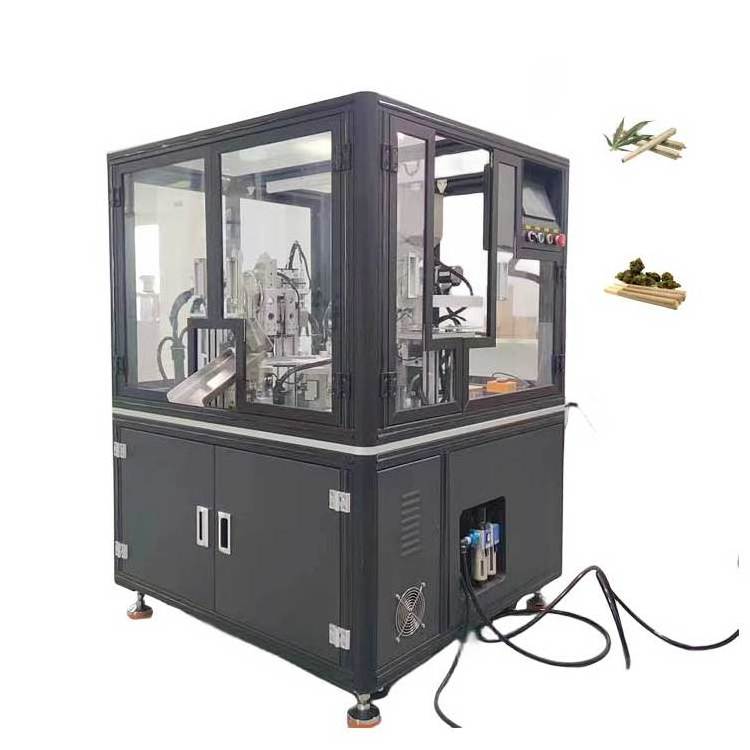

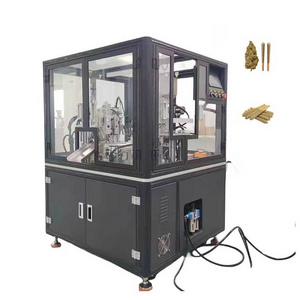

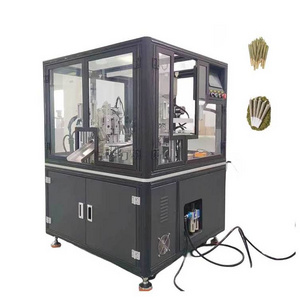

USA Blooming Dutch Fold 109 & 98 Pre Roll Cone Filling Machine

-

Keywords:

-

Automatic Fold Twist Cutting Fold cones pre roll filling machine

-

Control:

-

PLC

-

Filling speed:

-

1000-1500 pcs/hour

-

Applicable roll size:

-

109/98/84mm(Customized)

-

Optimal filling range:

-

0.5g-1.5g (filling parts need to be replaced)

-

Material hopper capacity:

-

5L/5kg

-

Suitable for:

-

Pre rolls filling machine

-

Type:

-

Cone Filling Machine

-

After-sales Service Provided:

-

Online Support

Quick Details

-

Production Capacity:

-

1000-1500pcs/min

-

Application:

-

Pre Roll cone Filling Machine

-

Voltage:

-

110v-220v,50/60Hz

-

Place of Origin:

-

Netherlands

-

Year:

-

2024

-

Brand Name:

-

FillinMachine

-

Dimension(L*W*H):

-

1250 * 1200 * 1700mm

-

Weight (KG):

-

280

-

Product name:

-

USA Blooming Dutch Fold 109 & 98 Pre Roll Cone Filling Machine

-

Keywords:

-

Automatic Fold Twist Cutting Fold cones pre roll filling machine

-

Control:

-

PLC

-

Filling speed:

-

1000-1500 pcs/hour

-

Applicable roll size:

-

109/98/84mm(Customized)

-

Optimal filling range:

-

0.5g-1.5g (filling parts need to be replaced)

-

Material hopper capacity:

-

5L/5kg

-

Suitable for:

-

Pre rolls filling machine

-

Type:

-

Cone Filling Machine

-

After-sales Service Provided:

-

Online Support

Marketing Campaign

Specification

|

item

|

value

|

|

Product name

|

automatic customize pre roll commercial machine for pre joint glass tip cone filling machine

|

|

Keywords

|

Automatic Fold Twist Cutting Fold cones pre roll filling machine

|

|

Control

|

PLC

|

|

Filling speed

|

1000-1500 pcs/hour

|

|

Applicable roll size

|

109/98/84mm(Customized)

|

|

Optimal filling range

|

0.5g-1.5g (filling parts need to be replaced)

|

|

Material hopper capacity

|

5L/5kg

|

|

Suitable for

|

Pre rolls filling machine

|

|

Type

|

Cone Filling Machine

|

|

After-sales Service Provided

|

Online Support

|

Recommend Products

Products Description

Cone filling Machine applications

automatic customize pre roll commercial machine for pre joint glass tip cone filling machine

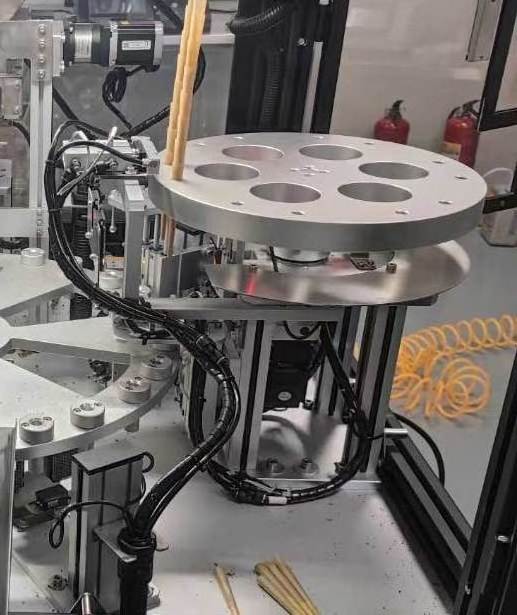

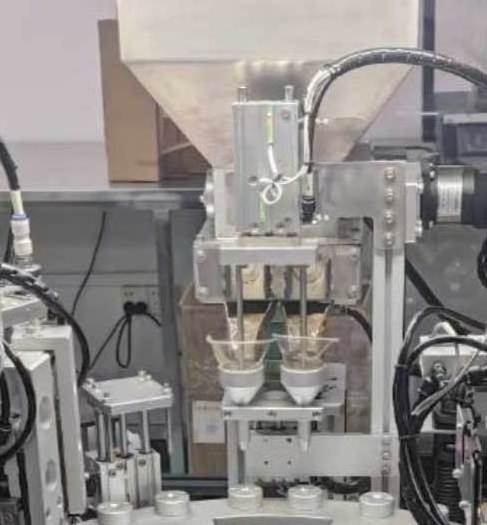

This device can achieve a fully automatic process of adding materials,weighing,filling,vibrating extrusion,twisting,cutting excess waste from paper tubes,flattening,and discharging.

Working principle of the device:

human-machine interaction is achieved through touch screen display. PLC programming coordinates and controls the execution of actions at various workstations. The principle of workstation operation is adopted.

(1.Manually clip into the predetermined paper cutting station. -2.Automatic filling of tobacco material. -3.Pre pressing of filling. -4.Sealing. -5.Cut off excess paper. -6.Sealing and flattening. -7.Discharge) We provide several sizes and types (109 98 84 116mm) of automated pre-roll machine,We guide you through the pre-roll automation filling process. As We know automated pre-roll machines normally fail due to many variables – like the particle size of the flower (coarse), to the moisture content(Very Sticky), to the pre-rolled cones.We are a mechanical factory,You can trust us,We have our team to support to help customer to automate their pre-roll filling process.

(1.Manually clip into the predetermined paper cutting station. -2.Automatic filling of tobacco material. -3.Pre pressing of filling. -4.Sealing. -5.Cut off excess paper. -6.Sealing and flattening. -7.Discharge) We provide several sizes and types (109 98 84 116mm) of automated pre-roll machine,We guide you through the pre-roll automation filling process. As We know automated pre-roll machines normally fail due to many variables – like the particle size of the flower (coarse), to the moisture content(Very Sticky), to the pre-rolled cones.We are a mechanical factory,You can trust us,We have our team to support to help customer to automate their pre-roll filling process.

Buyer Evaluation

Our services

1. If there is a machine problem within 1 year of delivery,we can provide free spare parts replacement

2. Support returns within 2 days after payment,and cannot be returned after delivery.

3. English version user guide manuel and video

4. Exclusive after sale customer service

5. Before shipment, the machines have been successfully tested.

6. Support Certifications,CE certification,ISO9000

7. Respond Rate 100%,During working hours,the response time is less than 10 minutes.

2. Support returns within 2 days after payment,and cannot be returned after delivery.

3. English version user guide manuel and video

4. Exclusive after sale customer service

5. Before shipment, the machines have been successfully tested.

6. Support Certifications,CE certification,ISO9000

7. Respond Rate 100%,During working hours,the response time is less than 10 minutes.

Details Images

Hot Searches