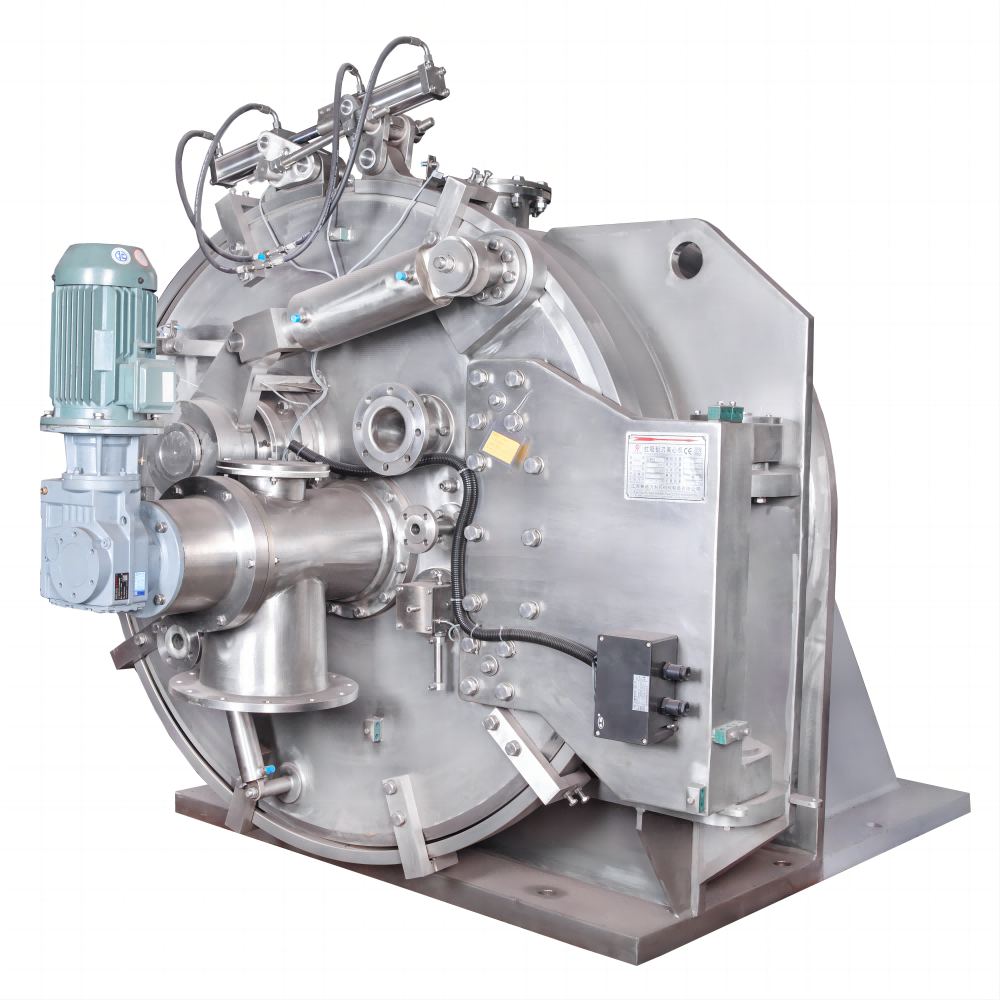

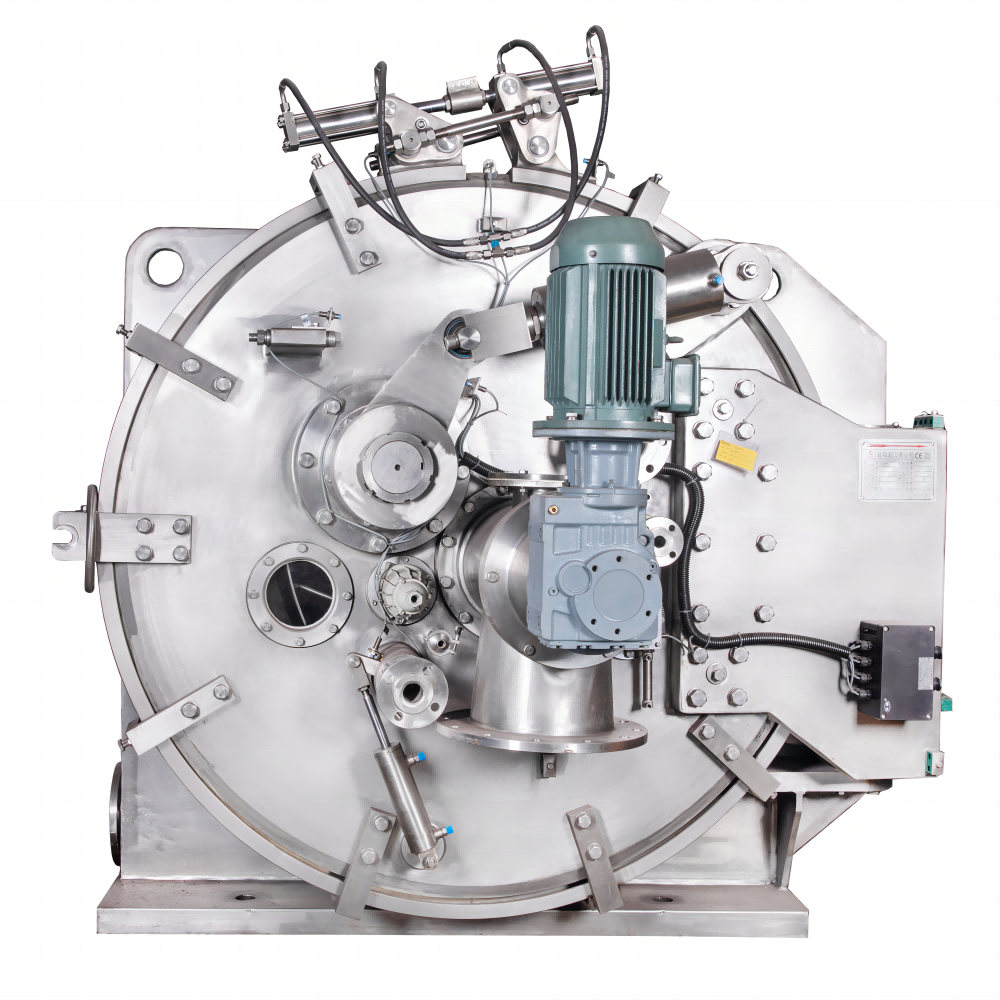

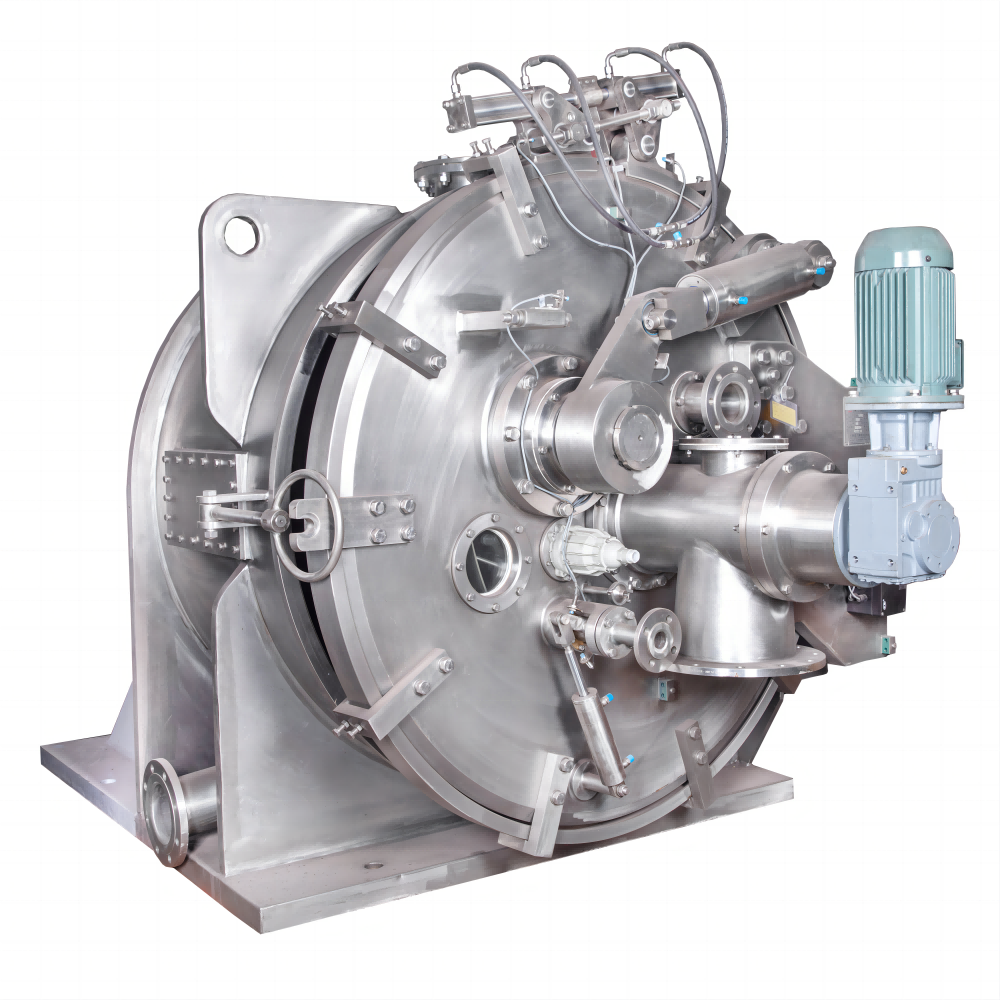

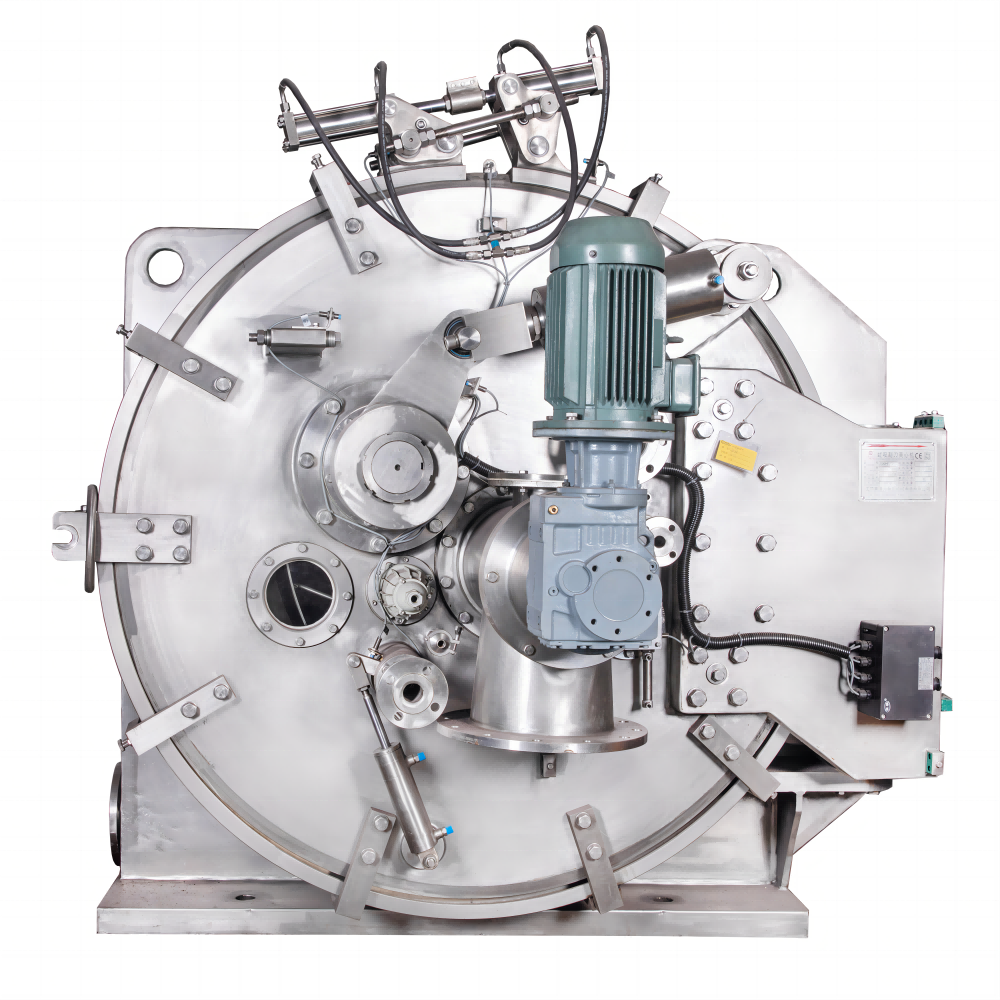

GKH series automatic siphon horizontal scraper centrifuge is a kind of solid and liquid separating machine with continuous running and intermittent discharging. It is with higher capacity and separating efficiency compared with GK(F) model.

This centrifuge adopts PLC control and speed regulated by inverter. Braking system adopts dynamic braking or regenerative braking. Full automatic cycle running and free switch between manual and automatic operating modes.

- Product Details

- {{item.text}}

Quick Details

-

Weight:

-

5800

-

Dimension(L*W*H):

-

2439*1900*2150mm

-

Application:

-

Chemical food industry

-

Function:

-

Seperation

-

Material:

-

Stainless Steel

-

Discharge type:

-

Peeler Discharge

-

Capacity:

-

140kg

-

Rotating Speed:

-

1500rpm

-

Control system:

-

DCS control, PLC control

-

Keyword:

-

Siphon device

-

Separation phase:

-

Two Phase Solid Liquid

-

Bowl Material:

-

Stainless Steel 304/316L/Duplex Steel

Quick Details

-

Place of Origin:

-

Jiangsu, China

-

Marketing Type:

-

New Product 2024

-

Brand Name:

-

Saideli

-

Weight:

-

5800

-

Dimension(L*W*H):

-

2439*1900*2150mm

-

Application:

-

Chemical food industry

-

Function:

-

Seperation

-

Material:

-

Stainless Steel

-

Discharge type:

-

Peeler Discharge

-

Capacity:

-

140kg

-

Rotating Speed:

-

1500rpm

-

Control system:

-

DCS control, PLC control

-

Keyword:

-

Siphon device

-

Separation phase:

-

Two Phase Solid Liquid

-

Bowl Material:

-

Stainless Steel 304/316L/Duplex Steel

Product Description

GKH series automatic siphon horizontal scraper centrifuge

Main Feature

Main features

1. Compared with the horizontal scraper discharge centrifuge of the same specification, the filtration speed is faster and the moisture content of the cake is lower.

2. Adjusting the position of the siphon pipe suction port can adjust the filtration speed, realizing different filtration speeds for feeding, separating, cake washing and cake dehydration, so that the centrifuge is always working in a best working condition, and the equipment operates smoothly with less vibration and noise.

3. At the end of the scraping cycle, the residual filter cake is regenerated and re-suspended by adding backflush liquid through the backflushing pipe to backflush and remove the residual filter cake.

4. Residual filter cake automatic removal device(national patent) is optional.

2. Adjusting the position of the siphon pipe suction port can adjust the filtration speed, realizing different filtration speeds for feeding, separating, cake washing and cake dehydration, so that the centrifuge is always working in a best working condition, and the equipment operates smoothly with less vibration and noise.

3. At the end of the scraping cycle, the residual filter cake is regenerated and re-suspended by adding backflush liquid through the backflushing pipe to backflush and remove the residual filter cake.

4. Residual filter cake automatic removal device(national patent) is optional.

Specification

|

Item/Model

|

GKH-450

|

GKH-800

|

GKH-1000

|

GKH-1050

|

GKH-1250

|

GKH-1350

|

GKH-1600

|

GKH-1800

|

GKH-2000

|

|

Drum diameter (mm)

|

450

|

800

|

1000

|

1050

|

1250

|

1350

|

1600

|

1800

|

2000

|

|

Drum height (mm)

|

300

|

450

|

500

|

500

|

630

|

680

|

1000

|

1250

|

1400

|

|

Drum volume (L)

|

21

|

110

|

200

|

210

|

335

|

450

|

879

|

1390

|

1923

|

|

Loading capacity(Kg)

|

26

|

140

|

250

|

260

|

500

|

585

|

1100

|

1800

|

2400

|

|

Max. Speed (r/min)

|

2600

|

1500

|

1400

|

1400

|

1200

|

1200

|

950

|

900

|

950

|

|

Max. Separating factor (N)

|

1700

|

1007

|

1095

|

1150

|

1006

|

1086

|

808

|

815

|

1008

|

|

Main Motor power

(Kw) |

15

|

37

|

45

|

45

|

75/90

|

90

|

132

|

160

|

200

|

|

Size(including shock absorber) (mm)

|

1800×

1375

×1902 |

2439×

1900

×2150 |

3050×

2400

×2192 |

3050×

2400

×2192 |

3875×

2500

×2612 |

4300×

2500×2906

|

5620×

3200

×3930 |

5862×

3600

×3910 |

7577×

3700

×4053 |

|

Weight (Kg)

|

2500

|

5800

|

6200

|

7800

|

8000

|

11000

|

20000

|

24500

|

35000

|

|

Weight including platform (Kg)

|

2500

|

10800

|

13200

|

15000

|

16000

|

20000

|

39000

|

52500

|

62000

|

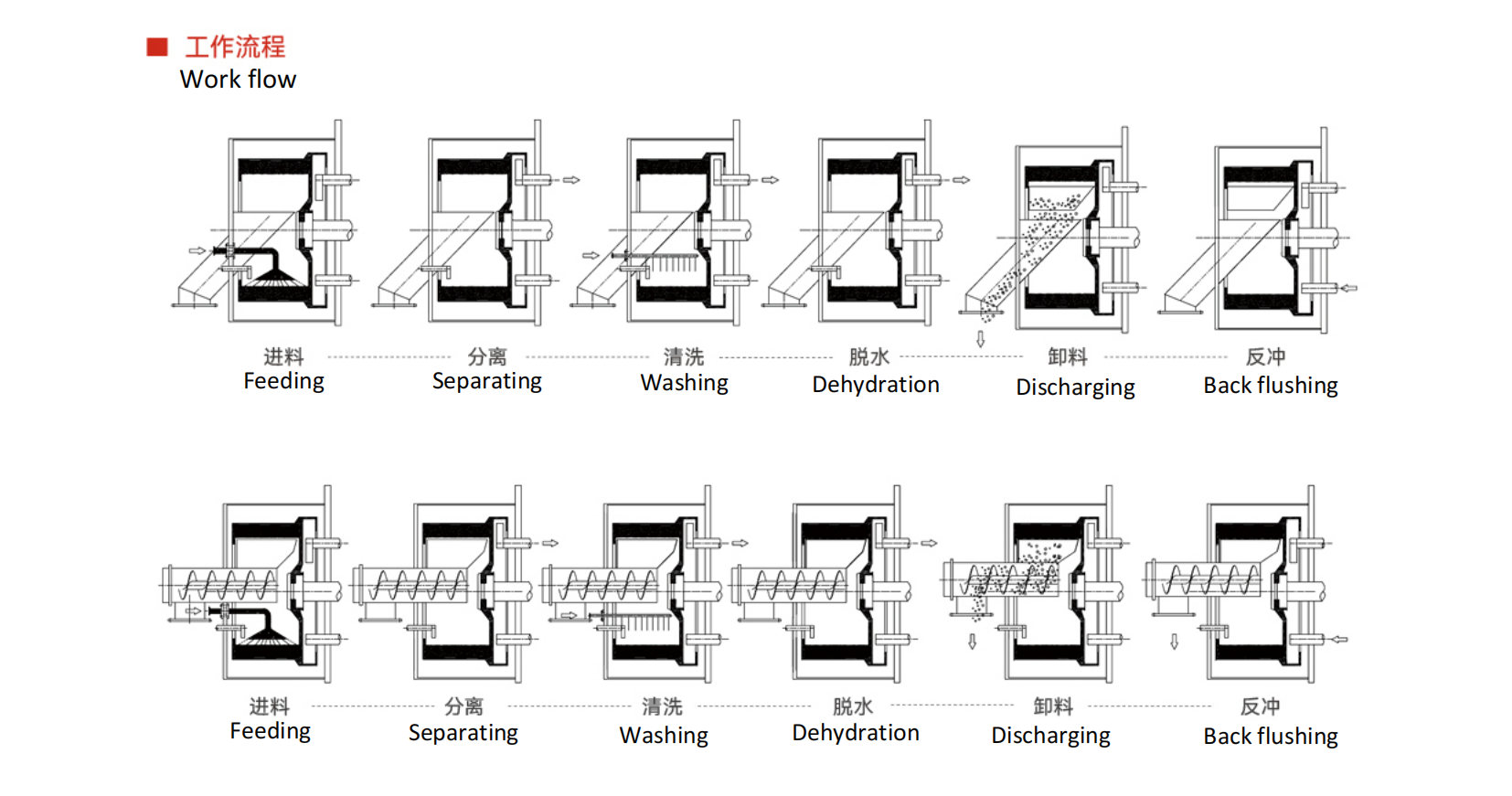

Working principle

Working principle

In addition to the driving force of an ordinary scraper discharge centrifuge, the horizontal siphon scraper centrifuge has a siphon pumping force similar to a vacuum pipe.

When the centrifuge is empty, the liquid is filled into the siphon chamber by the backflushing pipe, and the liquid is pressed into the outer drum gap by the siphon chamber through the through-hole of the drum. One side removes the air from the siphon pipe, and the other side forms a layer of liquid on the filtration medium, so as to make the feeding material evenly distributed. Then the feeding starts while the siphon pipe rotates to a certain position, and after a certain period of time it rotates again to the required a lower position, and at the end of the feeding, the siphon pipe is turned to the lowest position (the position of the maximum diameter of the siphon chamber). After suspension goes into the drum, solid particles are retained in the filter cloth,

while the liquid is filtered through the filter cloth and filtering the inner drum, gathered in the gap between the inner and outer drum, and enters the siphon chamber through the drum and the siphon chamber holes, and then pumped away by the siphon pipe. After the deposited solids continue to be thrown dry, the cylinder promotes the scraper rotation to begin to scrape the materials, and then the materials are slid out of the machine through the hopper. Clean the screen after discharging. The siphon scraper centrifuge not only rinses the filter cloth in the drum, but also adds rinse water to the siphon chamber from the backflushing pipe.The up and down rotation of the siphon pipe is controlled to pulsating backflush the screen from below the inner drum. Determine the rinsing time according to the characteristics of the material, and at this time, after the completion of the washing screen automatically enter the next cycle of work.

while the liquid is filtered through the filter cloth and filtering the inner drum, gathered in the gap between the inner and outer drum, and enters the siphon chamber through the drum and the siphon chamber holes, and then pumped away by the siphon pipe. After the deposited solids continue to be thrown dry, the cylinder promotes the scraper rotation to begin to scrape the materials, and then the materials are slid out of the machine through the hopper. Clean the screen after discharging. The siphon scraper centrifuge not only rinses the filter cloth in the drum, but also adds rinse water to the siphon chamber from the backflushing pipe.The up and down rotation of the siphon pipe is controlled to pulsating backflush the screen from below the inner drum. Determine the rinsing time according to the characteristics of the material, and at this time, after the completion of the washing screen automatically enter the next cycle of work.

Machining center

Customer Photos

FAQ

1. who are we?

We are based in Jiangsu, China, start from 1992,sell to Domestic Market(78.00%),North America(5.00%),Southeast Asia(3.00%),South Asia(2.00%),South America(2.00%),Eastern Asia(2.00%),Oceania(1.00%),Africa(1.00%),Southern Europe(1.00%),Northern Europe(1.00%),Central America(1.00%),Western Europe(1.00%),Mid East(1.00%),Eastern Europe(1.00%). There are total about 1000+ people in our office.

2. how can we guarantee quality?

Always a pre-production sample before mass production;

Always final Inspection before shipment;

3.what can you buy from us?

Centrifuge,MVR system,Lamella plate

4. why should you buy from us not from other suppliers?

Jiangsu Saideli is a National High-tech enterprises integrating scientific research, sales and manufacture of centrifugal machinery and drying machinery. Established in 1953, with 54 years experience.

5. what services can we provide?

Accepted Delivery Terms: FOB,CIF;

Accepted Payment Currency:USD,CNY;

Accepted Payment Type: T/T,L/C;

Language Spoken:English,Chinese

We are based in Jiangsu, China, start from 1992,sell to Domestic Market(78.00%),North America(5.00%),Southeast Asia(3.00%),South Asia(2.00%),South America(2.00%),Eastern Asia(2.00%),Oceania(1.00%),Africa(1.00%),Southern Europe(1.00%),Northern Europe(1.00%),Central America(1.00%),Western Europe(1.00%),Mid East(1.00%),Eastern Europe(1.00%). There are total about 1000+ people in our office.

2. how can we guarantee quality?

Always a pre-production sample before mass production;

Always final Inspection before shipment;

3.what can you buy from us?

Centrifuge,MVR system,Lamella plate

4. why should you buy from us not from other suppliers?

Jiangsu Saideli is a National High-tech enterprises integrating scientific research, sales and manufacture of centrifugal machinery and drying machinery. Established in 1953, with 54 years experience.

5. what services can we provide?

Accepted Delivery Terms: FOB,CIF;

Accepted Payment Currency:USD,CNY;

Accepted Payment Type: T/T,L/C;

Language Spoken:English,Chinese

Hot Searches