- Product Details

- {{item.text}}

Quick Details

-

Place of Origin:

-

Jiangsu, China

-

Brand Name:

-

lanchuang

-

Dimension(L*W*H):

-

Cutomer's Request

-

Weight:

-

0.5 KG

-

After-sales Service Provided:

-

Engineers available to service machinery overseas

-

Sheath Material:

-

Stainless Steel Ss304/316/321

-

Heating elements:

-

Resistance Wire Cr-Ni

-

Insulation material:

-

High-purity Mgo

-

Working Temperature:

-

800℃

-

MOQ:

-

20pcs

-

Diameter:

-

12mm

-

Length:

-

150mm

-

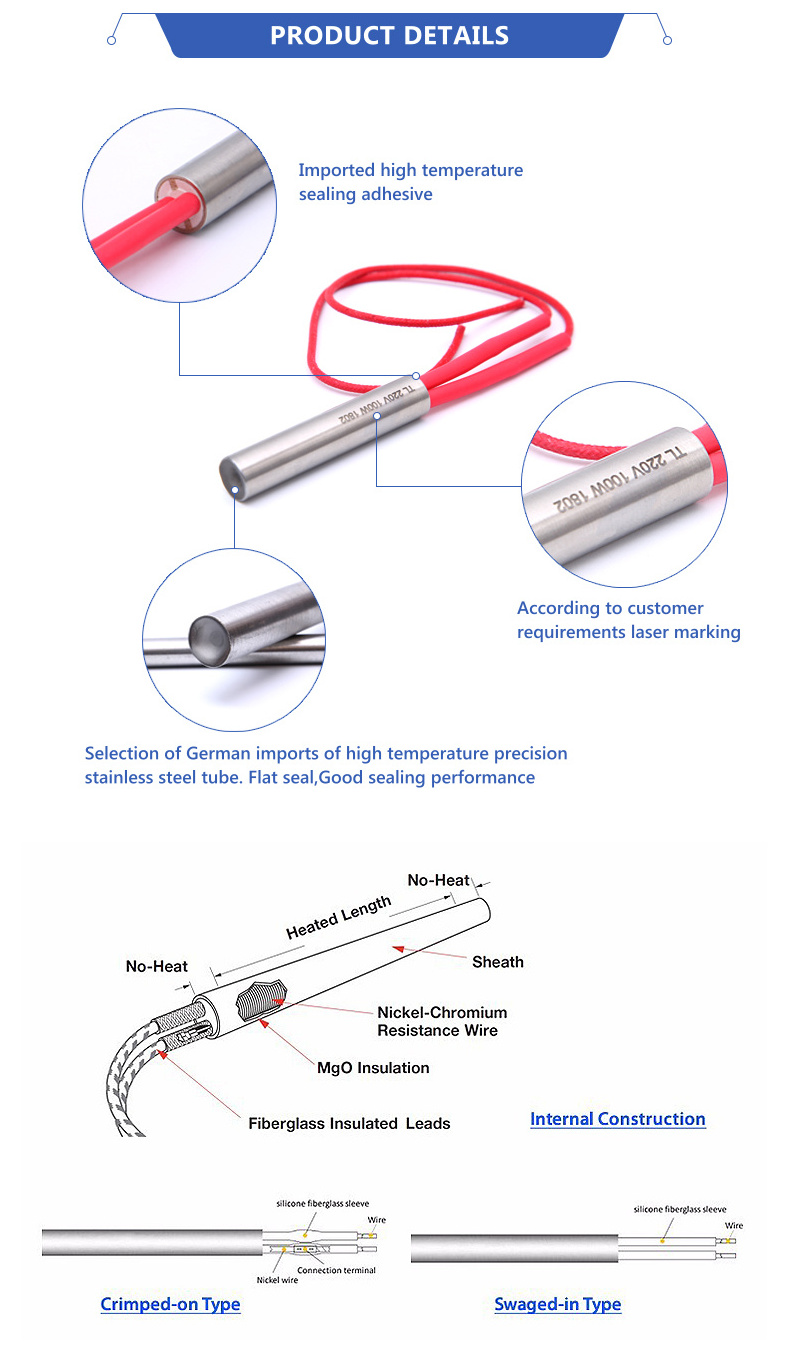

Lead Connection Option:

-

Crimped or Swaged leads

-

Length tolerance:

-

±1mm

Quick Details

-

Type:

-

Duct Heater

-

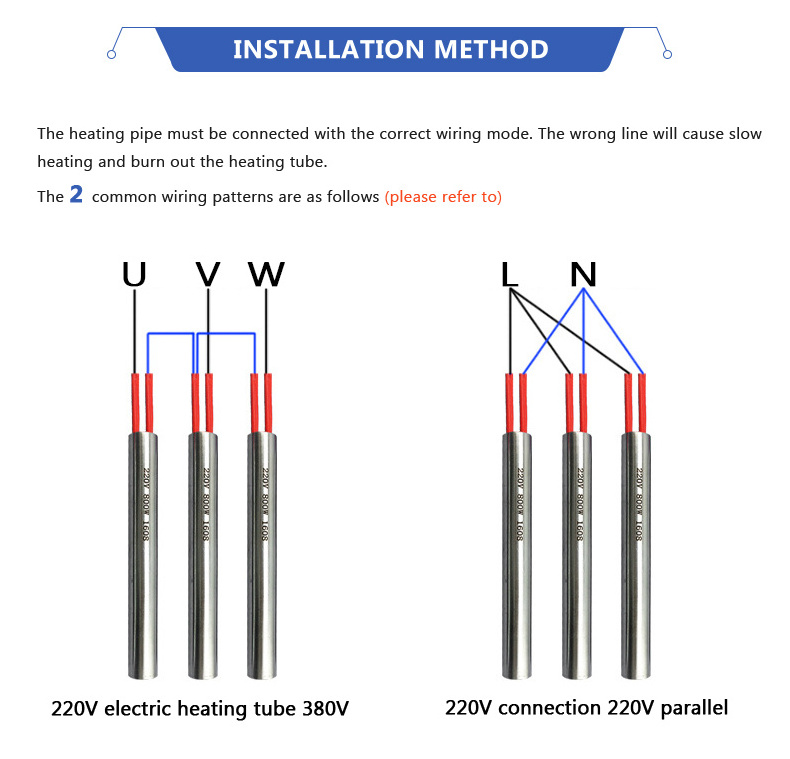

Power Source:

-

Electric

-

Voltage:

-

12-480v(customized)

-

Place of Origin:

-

Jiangsu, China

-

Brand Name:

-

lanchuang

-

Dimension(L*W*H):

-

Cutomer's Request

-

Weight:

-

0.5 KG

-

After-sales Service Provided:

-

Engineers available to service machinery overseas

-

Sheath Material:

-

Stainless Steel Ss304/316/321

-

Heating elements:

-

Resistance Wire Cr-Ni

-

Insulation material:

-

High-purity Mgo

-

Working Temperature:

-

800℃

-

MOQ:

-

20pcs

-

Diameter:

-

12mm

-

Length:

-

150mm

-

Lead Connection Option:

-

Crimped or Swaged leads

-

Length tolerance:

-

±1mm

Product Description

Description of Cartridge Heating Element

Classical structure of cartridge heater (Popular structure) is same to heating tube,Generally consists of five parts:Insulator,

sealing material,leading rods, filling material, electric wire, metal protective tube, terminal.Coil electric wire and leading rod

are set in the metal protective tube.

manufacturing process : put coil heating wires through the seamless steel pipe, copper or aluminum tube, Using filling machine more to fill insulation and thermal oxidation object evenly in the gaps,such as Crystal magnesium oxide powder (alumina or clean quartz sand are all available) etc.,And then use shrink tube machine contract pipe diameter, make oxide medium dense(make density achieves above 3.3 g/cm3),Ensure the heating wire cut off from the air, the center position touch pipe wall and don’t offset.It can increase heating power more than ten times per unit area.the using life can be improved to more than 10 years,Comparing with large heating power electric element ,tubular heaters can save 5% material,Thermal efficiency can reach above 90%.

Classical structure of cartridge heater (Popular structure) is same to heating tube,Generally consists of five parts:Insulator,

sealing material,leading rods, filling material, electric wire, metal protective tube, terminal.Coil electric wire and leading rod

are set in the metal protective tube.

manufacturing process : put coil heating wires through the seamless steel pipe, copper or aluminum tube, Using filling machine more to fill insulation and thermal oxidation object evenly in the gaps,such as Crystal magnesium oxide powder (alumina or clean quartz sand are all available) etc.,And then use shrink tube machine contract pipe diameter, make oxide medium dense(make density achieves above 3.3 g/cm3),Ensure the heating wire cut off from the air, the center position touch pipe wall and don’t offset.It can increase heating power more than ten times per unit area.the using life can be improved to more than 10 years,Comparing with large heating power electric element ,tubular heaters can save 5% material,Thermal efficiency can reach above 90%.

Specification

|

Industrial Heater

|

L shape cartridge heater

|

|

Resistance Heating Wire

|

NiCr2080

|

|

Sheath

|

SS304/316/321/Incoloy 800 /840

|

|

Max.Temp

|

800 Degree Celsius

|

|

Wattage Tolerance

|

+5%, -10%

|

|

Resistance Tolerance

|

+10%,-5%

|

|

Voltage Avialable

|

380V,240V,220V,110V,36V,24V or 12V

|

|

Length Tolerance

|

±1mm

|

|

Diameter Tolerance

|

-0.02mm

|

|

Standard Cold Zone

|

5-10mm

|

|

Insulation Resistance (cold)

|

≥500MΩ

|

|

Max.Leakage Current (cold)

|

≤0.5mA

|

|

Thermocouple

|

Type K, Type J

|

Related Products

Recommend Products

Packing & Delivery

Certifications

Feedback

Hot Searches