- Product Details

- {{item.text}}

Quick Details

-

Brand Name:

-

monde, ORNATE

-

Weight:

-

1500 KG

-

Keyword:

-

Rotary Vibrating Separator

-

Layer:

-

3

-

Color:

-

Yellow or customized

-

Brand:

-

MINGDE

-

Material:

-

Hardox+BISalloy+Q345

-

Certification:

-

ISO9001:2008, CE

-

feeding height:

-

2800-4100

Quick Details

-

Type:

-

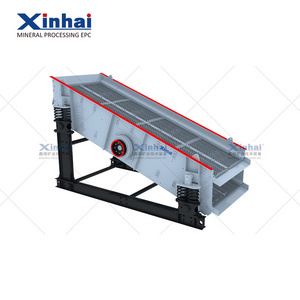

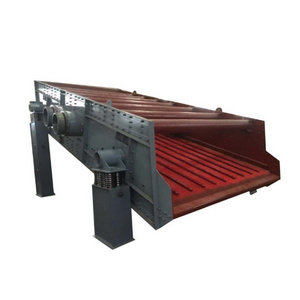

Linear Vibrating Screen

-

Marketing Type:

-

Hot Product 2024

-

Place of Origin:

-

Shandong, China

-

Brand Name:

-

monde, ORNATE

-

Weight:

-

1500 KG

-

Keyword:

-

Rotary Vibrating Separator

-

Layer:

-

3

-

Color:

-

Yellow or customized

-

Brand:

-

MINGDE

-

Material:

-

Hardox+BISalloy+Q345

-

Certification:

-

ISO9001:2008, CE

-

feeding height:

-

2800-4100

New Tracked Vibrating Screen Customized mobile screener

Product Description

Mobile screening station is a kind of high efficiency screening equipment, which adopts crawler driving mode, advanced technology and complete functions. Because of its unique optimized dynamic design and intelligent process control system, it has strong and durable, stable and reliable high-efficiency screening ability, which is an ideal choice in many independent screening or multi-stage mobile crushing and screening process.

Advantages

1. High efficiency screening: dynamic optimization design, complete screening system, without on-site installation and debugging,can be put into production quickly;

2. To meet the diversified screening requirements: plate feeding system is selected to achieve the screening efficiency of special materials;

3. The two-layer design is widely used: the two-layer screen design of the screening machine can screen up to three kinds of end products with practical value, and each finished product conveyor belt can be hydraulically folded to realize the whole machine transportation;

4. Convenient maintenance and transportation: the vibrating screen can be lifted and lowered by hydraulic pressure, which is convenient for maintenance and screen replacement;

5. It can realize fast site transfer operation: the intelligent wireless remote control device has good site mobility and trafficability, and can adapt to various complex construction environments such as mountains and wetlands.

1. High efficiency screening: dynamic optimization design, complete screening system, without on-site installation and debugging,can be put into production quickly;

2. To meet the diversified screening requirements: plate feeding system is selected to achieve the screening efficiency of special materials;

3. The two-layer design is widely used: the two-layer screen design of the screening machine can screen up to three kinds of end products with practical value, and each finished product conveyor belt can be hydraulically folded to realize the whole machine transportation;

4. Convenient maintenance and transportation: the vibrating screen can be lifted and lowered by hydraulic pressure, which is convenient for maintenance and screen replacement;

5. It can realize fast site transfer operation: the intelligent wireless remote control device has good site mobility and trafficability, and can adapt to various complex construction environments such as mountains and wetlands.

Hot Searches