[

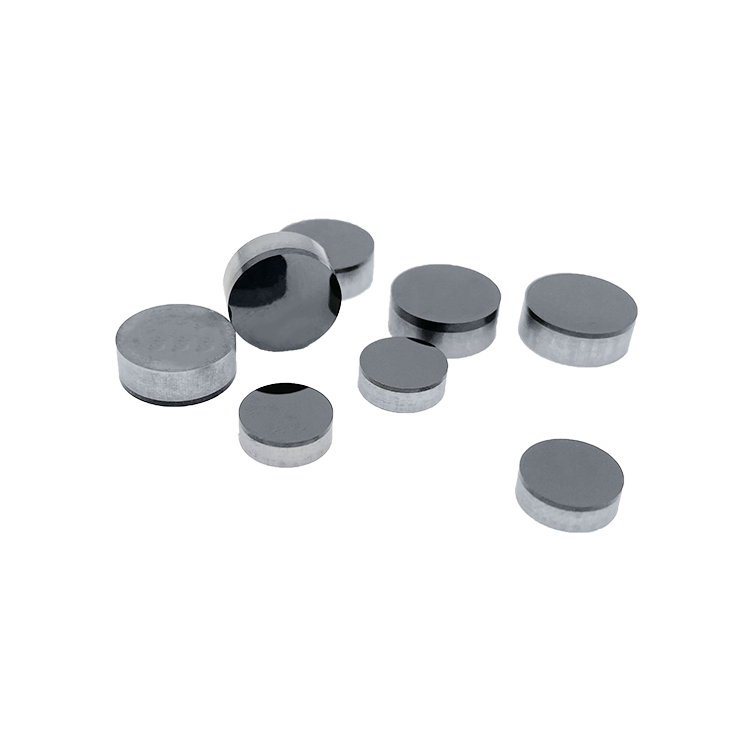

Item

]

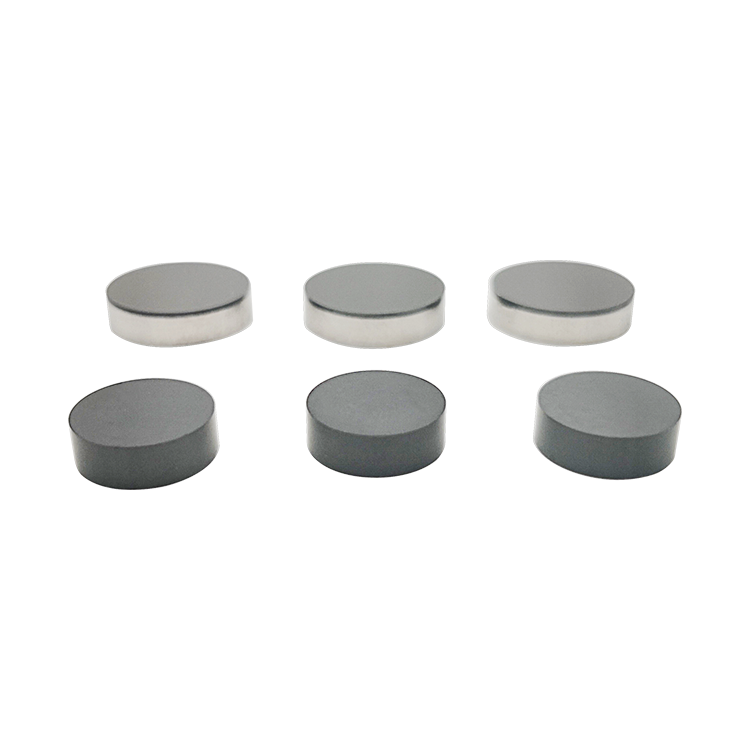

PCD

CBN Inserts

[ Thickness of diamond ]

0.5~1.0mm

[ Specification ]

According to the customer's requirements

[

Feature

]

1.high hardness and wearability

2.sorts of shapes and sizes

3.high toughness

2.sorts of shapes and sizes

3.high toughness

Poly Crystalline Diamond PCD cutter

with carbide support

PDC the hardness and abrasion resistance of diamond with the impact resistance of tungsten carbide,and provides faster,more

durable and more cost-effective drilling.

durable and more cost-effective drilling.

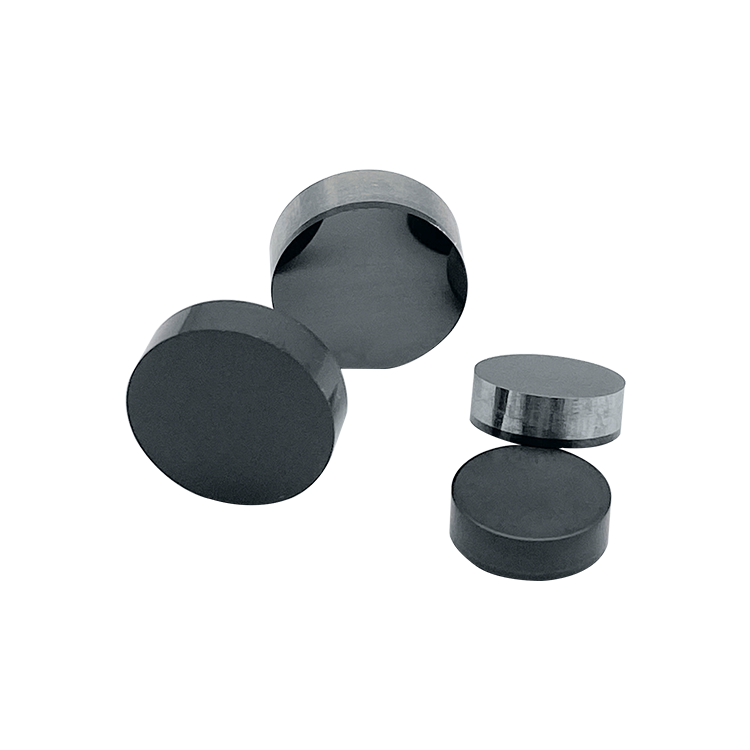

Cubid Boron Nitride CBN cutter

CBN cutters can be double-sided grinding and have a longer service life.