We take part in various exhibitions at home and abroad every year.

- Product Details

- {{item.text}}

Quick Details

-

MF:

-

O2Si

-

EINECS No.:

-

231-545-4

-

Place of Origin:

-

Hubei, China

-

Appearance:

-

White Nano-Scaled Powder

-

Application:

-

Printing & Ink; Coating; Sealants; Rubber

-

Brand Name:

-

HIFULL

-

Model Number:

-

HL-260

-

Product name:

-

HIFULL factory price fumed silica HL-260

-

Type:

-

nano materials

-

primary particle size:

-

5- 50 nm

-

purity:

-

≥99.8%

-

HS code:

-

28112200

-

One bag dimension:

-

110cm*55cm*25cm

-

Country of Origin:

-

China

-

Advantage 1:

-

factory supply

-

Advantage 2:

-

ISO 9001

-

Advantage 3:

-

REACH and K-Reach certificate

Quick Details

-

CAS No.:

-

112945-52-5

-

Purity:

-

99.8%

-

Other Names:

-

Silicon Dioxide

-

MF:

-

O2Si

-

EINECS No.:

-

231-545-4

-

Place of Origin:

-

Hubei, China

-

Appearance:

-

White Nano-Scaled Powder

-

Application:

-

Printing & Ink; Coating; Sealants; Rubber

-

Brand Name:

-

HIFULL

-

Model Number:

-

HL-260

-

Product name:

-

HIFULL factory price fumed silica HL-260

-

Type:

-

nano materials

-

primary particle size:

-

5- 50 nm

-

purity:

-

≥99.8%

-

HS code:

-

28112200

-

One bag dimension:

-

110cm*55cm*25cm

-

Country of Origin:

-

China

-

Advantage 1:

-

factory supply

-

Advantage 2:

-

ISO 9001

-

Advantage 3:

-

REACH and K-Reach certificate

Exhibition and Certificates

Product Description

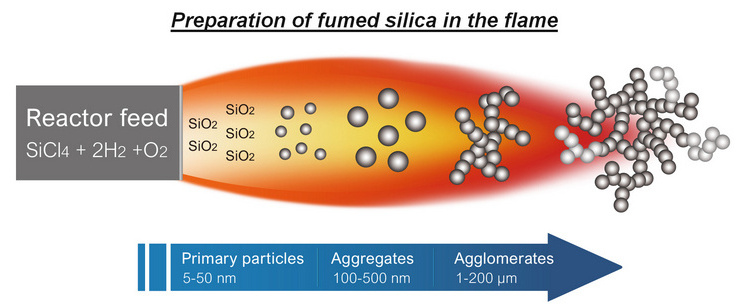

Pyrogenic silica hydrophilic fumed silica HL-260 with CAS 112945-52-5

Fumed silica, also known as pyrogenic silica, because it is produced in the flame. It is superfine chemical

products with

primary particle size 5 -50 nm

, which is divided into hydrophilic type and hydrophobic type according to their ndifferent surface treatment process.

Fumed silica is widely applied to the industries of silicone rubber, adhesives, sealants, paint, coating, resins, pharmaceuticals, composite materials, fertilizer, animal feed and food etc.

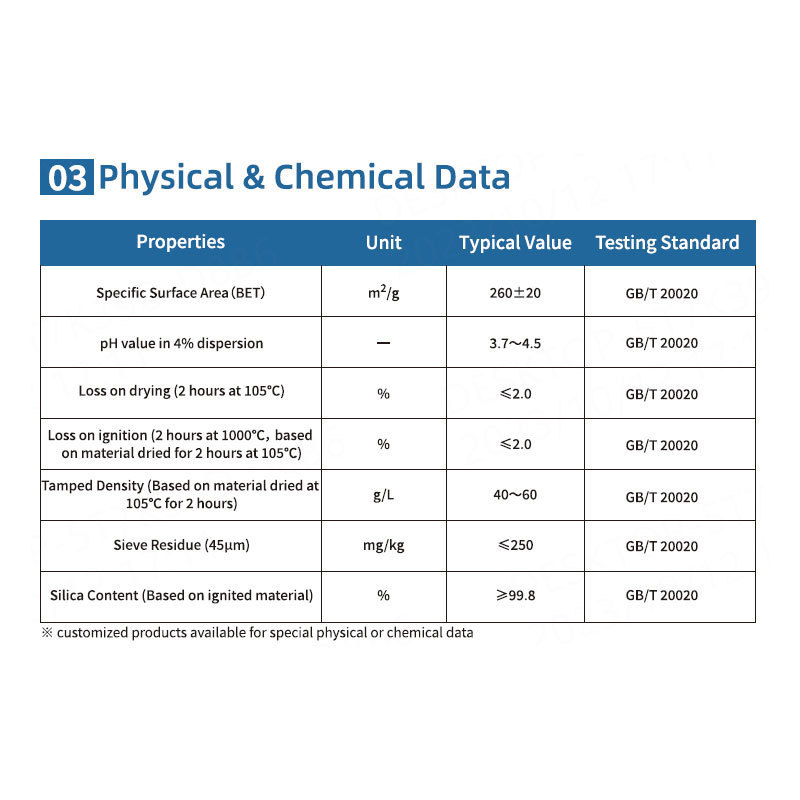

Characteristics of HL-260

HL-260 is hydrophilic fumed silica synthesized from the hydrolysis of high purity chlorsilane in a flame of oxygen and hydrogen at temperature over 1000 degree.

Its specific surface area is around 260m2/g.

|

P

hysical & Chemical Data of HL-260

|

|

|

|

|||

|

Properties

|

Unit

|

Typical Value

|

Testing Standard

|

|||

|

Specific surface area(BET)

|

m

2

/g

|

260±20

|

GB/T 20020

|

|||

|

pH in 4% dispersion

|

|

3.9~4.5

|

GB/T 20020

|

|||

|

Loss on drying

(2 hour at 105℃)

|

%

|

≤2.0

|

GB/T 20020

|

|||

|

Loss on ignition

(2 hour at 1000° based on material dried for 2 hours at 105℃)

|

%

|

≤2.0

|

GB/T 20020

|

|||

|

Sieve residue(45μm)

|

mg/kg

|

≤250

|

GB/T 20020

|

|||

|

Silica content

( Based on ignited material)

|

%

|

≥99.8

|

GB/T 20020

|

|||

|

Tamped density (based on material dried for 2 hours at 105℃)

|

g/dm²

|

40~60

|

GB/T 20020

|

|||

More products- HIFULL fumed silica

HIFULL fumed silica includes hydrophilic and hydrophobic grades. Below table is part of our main products, if you have any interesting, pls

click the "'Chat Now" button of right side to contact with us!

|

Grade

|

HL-200

|

HL-380

|

HB-139

|

HB-151

|

HB-615

|

HB-630

|

|||||

|

Form

|

white amorphous powder

|

|

|

|

|

|

|||||

|

Surface

area

(m2/g)

|

200±20

|

380±30

|

110±30

|

130±30

|

140±20

|

270±30

|

|||||

|

PH value

|

3.9-4.5

|

3.9-4.5

|

4.0-7.0

|

≥3.9

|

5.0-8.0

|

6.0-9.0

|

|||||

|

Loss on drying

(2h,105℃) % |

≤2.0

|

≤2.5

|

≤0.7

|

≤0.7

|

≤0.7

|

≤0.7

|

|||||

|

Loss on ignition (2h,1000℃) %

|

≤2.0

|

≤2.5

|

≤10

|

≤2.5

|

≤4.0

|

≤5.0

|

|||||

|

silica content (%)

|

≥99.8

|

|

|

|

|

|

|||||

|

Tamped density (g/dm²)

|

40-60

|

40-60

|

45-70

|

40-60

|

40-60

|

40-60

|

|||||

|

Surface treatment

|

No

|

No

|

PDMS

|

DDS

|

HMDS

|

HMDS

|

|||||

Product Application

Applications of HL-260

Coatings & printing inks

HTV& RTV silicone rubbers

UPR resins

Adhesives

Thermal materials

UPR resins

Adhesives

Thermal materials

Ceramic powder material

Personal care products

Food & Constructional materials

More Applications -- HIFULL fumed silica

Fumed silica is widely applied to the industries of silicone rubber, adhesives, sealants, paint, coating, resins, pharmaceuticals, composite materials, fertilizer, animal feed and food etc.

More applications, click the bottom of page to contact supplier!

More applications, click the bottom of page to contact supplier!

|

Application

|

|

Main Functions

|

Recommend Grade

|

Suggested Usage(%)

|

|

|

Silicone rubber

|

HTV silicone rubber

|

reinforcing, transparent

|

HL-200, HL-300, HL-380, HB-132

|

0.5 - 3

|

|

|

|

Silicone rubber insulator

|

reinforcing,insulate

|

HL-150,HL-200,HB-139

|

0.5 - 3

|

|

|

|

RTV silicone rubber

|

rheology control

|

HL-150,HL-200,HB Series

|

0.5 - 3

|

|

|

Powder coating

|

Corona discharge

|

free flowing, anti-caking, dispersion, charge control

|

HB-630,HB-151,HL-200,HL-300,HL-380

|

0.5 - 3

|

|

|

Varnish

|

PU,Acrylic acid, epoxy-polyester, amino

|

|

HB-630,HB-151,HL-200,HL-300

|

0.5 - 3

|

|

|

Liquid coating

|

industrial paint and marine paint

|

anti-sagging, anti-settling, thickening, thixotropy,leveling

|

HB-139,HB-151,HB-630

|

0.5 - 3

|

|

|

|

acrylic acid, polyester, nitro

|

anti-sagging, anti-settling, thickening, thixotropy

|

HL-200,HL-300

|

0.5 - 3

|

|

|

|

Epoxy, vinyl polyester, PU

|

anti-sagging, anti-settling, thickening, thixotropy

|

HB-151,HB-139

|

0.5 - 3

|

|

|

Sealant

|

PU

|

thixotropy,anti-sagging, water content control

|

HB-139,HB-151,HL-200

|

3 - 7

|

|

|

Adhesive

|

Epoxy

|

reinforcing, thixotropy, anti-sagging, thickening

|

HB-139,HB-151, HL-200, HL-300

|

1.5 - 3

|

|

|

Composite material

|

|

thixotropy, anti-settling, anti-sagging, thickening

|

HL-200, HL-300, HB-151, HB-139

|

0.5 - 3

|

|

Recommend Products

Why Choose Us

Hot Searches