- Product Details

- {{item.text}}

Quick Details

-

Place of Origin:

-

Hebei, China

-

Brand Name:

-

MINTAI

-

Voltage:

-

220V 380V 50HZ

-

Dimension(L*W*H):

-

1600*2200*1400mm

-

Weight:

-

1000 kg

-

Marketing Type:

-

New Product 2021

-

Core Components:

-

Frequency converter

-

PLC Brand:

-

Other

-

Product name:

-

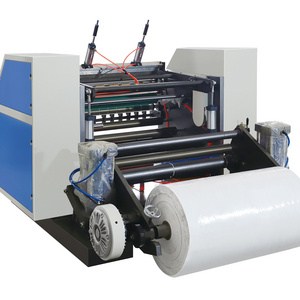

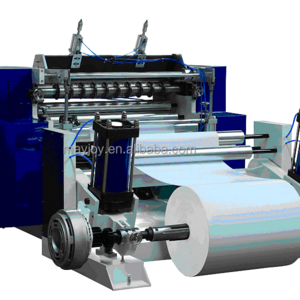

Slitting machine

-

Category:

-

Semi-automatic

-

Function:

-

slitting and rewinding machine face mask

-

Application:

-

Aluminum Foil

-

Keyword:

-

meltblown slitting and rewinding machine

-

Item:

-

paper slitting and rewinding machine

-

Key words:

-

fabric slitting and rewinding machine

-

Cutting materials:

-

Multiple Materials

-

kw:

-

nonwoven rewinder

-

Usage:

-

Roll Label Cutting

Quick Details

-

Type:

-

Paper Cutting Machine

-

Production Capacity:

-

100-300

-

Max. workable width:

-

1500mm

-

Place of Origin:

-

Hebei, China

-

Brand Name:

-

MINTAI

-

Voltage:

-

220V 380V 50HZ

-

Dimension(L*W*H):

-

1600*2200*1400mm

-

Weight:

-

1000 kg

-

Marketing Type:

-

New Product 2021

-

Core Components:

-

Frequency converter

-

PLC Brand:

-

Other

-

Product name:

-

Slitting machine

-

Category:

-

Semi-automatic

-

Function:

-

slitting and rewinding machine face mask

-

Application:

-

Aluminum Foil

-

Keyword:

-

meltblown slitting and rewinding machine

-

Item:

-

paper slitting and rewinding machine

-

Key words:

-

fabric slitting and rewinding machine

-

Cutting materials:

-

Multiple Materials

-

kw:

-

nonwoven rewinder

-

Usage:

-

Roll Label Cutting

thermal paper roll slitting and rewinding machine

Specification

|

Type

|

Slitting Rewinder

|

|

Place of Origin

|

China

|

|

origin

|

Hebei

|

|

Brand

|

MINTAI

|

|

VDC

|

220V 380V 50HZ

|

|

Size

|

1600*2200*1400mm

|

|

Weight

|

1000kg

|

|

Warranty

|

1 Year

|

|

Productivity m/min

|

100-300

|

|

Key Selling Points

|

High Productivity

|

|

Max. workable width

|

900mm

|

|

Machinery Test Report

|

Provided

|

|

Video outgoing-inspection

|

Provided

|

|

Marketing Type

|

New Product 2023

|

|

Warranty of core components

|

1 Year

|

|

Core Components

|

Frequency converter

|

Products Description

paper slitter machine is suitable for cutting big rolling packaging materials such as paper, paper board, kraft paper, culture paper, printing paper, laser paper, aluminum foil paper, paper, label,sticker, copper foil, aluminum foil,film(OPP, PE,

PVC,PP,PC), Non-woven cloth,melt-blown fabric .etc. Widely used in paper industry and printing industry.Stable Performance Paper Roll Slitting Machine with Belt Pulley The slitter is the corollary equipment of automatic die cutting

machine, which is suitable for slitting narrow paper web.It has automatic meter count and number count, quantity and length preset and decelerate till stopping functions.Auto Magnetic powder control for unwinding and rewinding.

Photoelectric eyes rectification for unwinding, synchronous belt to conveyor in internal structure.Distinctive machine design will improve working efficiency and reduce operation labor intensity , which is the optimal choice for narrow material slitting.The whole machine structure is compact, fast and with high efficiency. Operation is easy and steadily

Control Panel:

You can set slitting speed,running length,unwinding and rewinding tension on it. It is very easy for worker to operate the

machine.

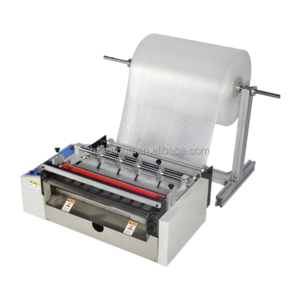

Slitting Blades:

This machine is standard equipped with full sets of slitting blades, min sltting width is 9mm. if you want to slit smaller

width,you can customize self-lock knives. It's easy to adjust the slitting width based on your products.

Edge / line Position Controller:

These photoelectric sensors are used to guide the rough material to make sure the slitting

rewinding effect is good.The photo sensors concentrate on the edge of the material. You can choose between a single sensor and two

sensors.

PVC,PP,PC), Non-woven cloth,melt-blown fabric .etc. Widely used in paper industry and printing industry.Stable Performance Paper Roll Slitting Machine with Belt Pulley The slitter is the corollary equipment of automatic die cutting

machine, which is suitable for slitting narrow paper web.It has automatic meter count and number count, quantity and length preset and decelerate till stopping functions.Auto Magnetic powder control for unwinding and rewinding.

Photoelectric eyes rectification for unwinding, synchronous belt to conveyor in internal structure.Distinctive machine design will improve working efficiency and reduce operation labor intensity , which is the optimal choice for narrow material slitting.The whole machine structure is compact, fast and with high efficiency. Operation is easy and steadily

Control Panel:

You can set slitting speed,running length,unwinding and rewinding tension on it. It is very easy for worker to operate the

machine.

Slitting Blades:

This machine is standard equipped with full sets of slitting blades, min sltting width is 9mm. if you want to slit smaller

width,you can customize self-lock knives. It's easy to adjust the slitting width based on your products.

Edge / line Position Controller:

These photoelectric sensors are used to guide the rough material to make sure the slitting

rewinding effect is good.The photo sensors concentrate on the edge of the material. You can choose between a single sensor and two

sensors.

Detailed Images

Hot Searches