ADVANTAGES OF LBJ

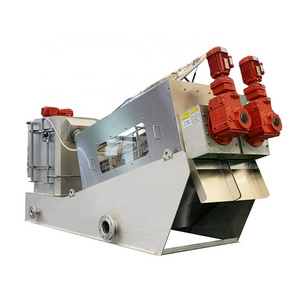

sludge dewatering screw press

* Insensitive to coarse material due to the wide gap between the screw conveyor and sieve

* No permanent sieve cleaning required, low wash water consumption

* Pneumatically controlled pressure cone system

* Defined sludge residence time

* Permanent movement of filter cake, minimized filter resistances

* Minimum wear due to the low speed of the compacting screw

* Minimized noise

* Low energy consumption

* High dewatering degrees with fibrous sludge

- Product Details

- {{item.text}}

Quick Details

-

Weight:

-

According to your order

-

Size:

-

According to your order

-

Power:

-

According to your order

-

Weight (KG):

-

1000 kg

-

Price:

-

Competitive

-

Feature:

-

Cost-effective,Self-cleaning,No clogging

-

Function:

-

sludge dewatering

-

Name:

-

sludge dewatering screw press

-

Application:

-

biological and physical-chemical sludge dewatering

-

Type:

-

screw press

-

Capacity:

-

0.5-1360kg DS/h

-

Control:

-

Full automatic control

-

Screw Anger:

-

Tungsten carbide treatment HRC80

Quick Details

-

Place of Origin:

-

Shandong, China

-

Brand Name:

-

LBJ

-

Material:

-

anti corrosion wooden case with foam inside, Stainless Steel 304 316

-

Weight:

-

According to your order

-

Size:

-

According to your order

-

Power:

-

According to your order

-

Weight (KG):

-

1000 kg

-

Price:

-

Competitive

-

Feature:

-

Cost-effective,Self-cleaning,No clogging

-

Function:

-

sludge dewatering

-

Name:

-

sludge dewatering screw press

-

Application:

-

biological and physical-chemical sludge dewatering

-

Type:

-

screw press

-

Capacity:

-

0.5-1360kg DS/h

-

Control:

-

Full automatic control

-

Screw Anger:

-

Tungsten carbide treatment HRC80

Product Overview

Cost-effective sludge dewatering screw press for biological and physical-chemical sludge

Reduce your sludge dewatering costs

With its longstanding industrial experience, LBJ is your solution provider and sludge screw press manufacturer for

cost-effective sludge dewatering, to deal with a wide range types of sludge. That being said, LBJ Screw Press unit

is suitable to handle both biological and physical-chemical types of sludge.

With its longstanding industrial experience, LBJ is your solution provider and sludge screw press manufacturer for

cost-effective sludge dewatering, to deal with a wide range types of sludge. That being said, LBJ Screw Press unit

is suitable to handle both biological and physical-chemical types of sludge.

Sludge dewatering treatment with LBJ effectively generates dewatered cake with high dry solids content and a good quality of centrate water, resulting in significant sludge volume reduction. Hence, costs associated with sludge disposal

will be minimized.

will be minimized.

The LBJ unit consists of pre-assembled components which enable the dewatering system to be flexible and easy to install, either as part of a total wastewater treatment solution project or as a stand-alone system in a new or existing plant. Furthermore, the smart design configuration reserves low footprint for the total sludge dewatering system with a LBJ unit.

FEATURES AT A GLANCE

sludge dewatering screw press

dewatering screw press

dewatering screw

PRODUCT SPECIFICATIONS

|

Parameter

|

Unit

|

Cost-effective sludge dewatering screw press for biological and physical-chemical sludge model

|

|

|

|

|

||||

|

|

|

LBJ201

|

LBJ131

|

LBJ301

|

LBJ401

|

LBJ403

|

||||

|

Solids Handling Capacity

|

kg/h

|

|

For Feed Sludge Concentration of 2g/L to 5g/L (0.2-0.5%)of solids

|

|

|

|

||||

|

3

|

Operating weight

|

20

|

6

|

40

|

400

|

300

|

||||

|

4

|

Max. tractive force

|

|

For Feed Sludge Concentration of 5g/L to 5g/L (0.5-5.0%)of solids

|

|

|

|

||||

|

5

|

Max. breakout force

|

30

|

10

|

60

|

140

|

420

|

||||

|

Typical Dewatered Cake Dry Solids Content

|

%DS

|

15-20%

|

60kN

|

|

|

|

||||

|

Number of Screws

|

|

1

|

1

|

1

|

1

|

3

|

||||

|

Screw Diameter

|

mm

|

200

|

130

|

300

|

400

|

400

|

||||

Benefits of

Cost-effective sludge dewatering screw press for biological and physical-chemical sludge:

* Single-step dewatering from as low as 0.2% dry solids content to 15-20%DS cake (WWTP sludges)

* High recovery rate >95%

* Simple installation and small footprint

* Simple automatic (or manual) operation

* Low energy consumption

* Low wash water consumption

* Simple and low maintenance

* Low noise and vibration levels

* Suitable for a wide range of applications

* High quality workmanship

* Control Panel compliant with AS/NZ 3000

* High recovery rate >95%

* Simple installation and small footprint

* Simple automatic (or manual) operation

* Low energy consumption

* Low wash water consumption

* Simple and low maintenance

* Low noise and vibration levels

* Suitable for a wide range of applications

* High quality workmanship

* Control Panel compliant with AS/NZ 3000

sludge dewatering screw press

Screw Anger:Tungsten carbide treatment HRC80, avoiding deformation.

dewatering screw press

Electric control cabinet can be Touch Screen,in door, Out door, PLC, ANTI-EXPLOSION etc.

dewatering screw

Fixed and Moving ring are all manually polished with polymer grains between screw and rings.

SALES AND SERVICE NETWORK

sludge dewatering screw press

in

Philippines

dewatering screw press

in India

dewatering screw

in USA

SIMILAR PRODUCTS

FAQ

Q1:How to choose the right model?Do you have the equipment working video on site?

A1:You can get the instant answer by clicking the Online Messenger 24hours/7days .

Q2:How about the after-sale service?

A2:Spare/consumable parts and accessories, personnel training, modification and upgrade, maintenance and full service are all welcomed 24hours/7days .

Main parts ,screw and screen are made of heat treated stainless steel , durable.

Q3: What type of sludge is Sludge Dehydrator applicable to?

A3: It is applicable to various kinds of sludge such as waste activated sludge, oily sludge,dissolved-air flotation sludge and so on. The thickening mechanism of this equipment enables dehydrator not only highly-concentrated sludge but also low-concentrated sludge with ease.

Q4: What's the equipment used together with Sludge Dehydrator?

A4: Sludge pump, polymer dosing pump, washing pump, air compressor.

Q5: What about he features of the sludge dehydrator?

A5:Compact design and space saving,simple operation and maintenance,power saving,water saving,wide scope of application.

A1:You can get the instant answer by clicking the Online Messenger 24hours/7days .

Q2:How about the after-sale service?

A2:Spare/consumable parts and accessories, personnel training, modification and upgrade, maintenance and full service are all welcomed 24hours/7days .

Main parts ,screw and screen are made of heat treated stainless steel , durable.

Q3: What type of sludge is Sludge Dehydrator applicable to?

A3: It is applicable to various kinds of sludge such as waste activated sludge, oily sludge,dissolved-air flotation sludge and so on. The thickening mechanism of this equipment enables dehydrator not only highly-concentrated sludge but also low-concentrated sludge with ease.

Q4: What's the equipment used together with Sludge Dehydrator?

A4: Sludge pump, polymer dosing pump, washing pump, air compressor.

Q5: What about he features of the sludge dehydrator?

A5:Compact design and space saving,simple operation and maintenance,power saving,water saving,wide scope of application.

Q6:How about the delivery time?

A6:Common sludge screw press are in stock.

Q7: Can you guarantee your quality?

A7: Of course. we have authoritative test reports and certificates to assure you the quality. Welcome to pay online to get safety.

A6:Common sludge screw press are in stock.

Q7: Can you guarantee your quality?

A7: Of course. we have authoritative test reports and certificates to assure you the quality. Welcome to pay online to get safety.

Hot Searches