- Product Details

- {{item.text}}

Quick Details

-

Ejector Stroke(mm):

-

220 mm

-

Ejector Force(kN):

-

280 kN

-

Theoretical Shot Volume(cm³):

-

9000 cm³

-

Injection Rate (g/s):

-

1192 g/s

-

Injection Weight (g):

-

8100 g

-

Screw Speed (rpm):

-

1 - 100 rpm

-

Screw diameter (mm):

-

135 mm

-

Screw L/D Ratio:

-

22.3

-

Distance between Tie Bars:

-

1350*1280 mm

-

Weight (KG):

-

76000 kg

-

Place of Origin:

-

Jiangsu, China

-

Open Stroke(mm):

-

1400 mm

-

Model Number:

-

BST-13000A

-

Brand Name:

-

BST MACHINE

-

Power (kW):

-

245 kW

-

Product name:

-

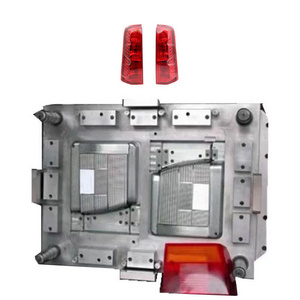

car bumper making machine

-

Machine weight:

-

76t

-

Oil tank capacity:

-

2400L

-

Screw Diameter:

-

38-40mm

-

Name:

-

car bumper moulding machine

-

Keyword:

-

car bumper injection moulding machine

-

Injection pressure:

-

166Mpa

-

MACHINE DIMENSION:

-

13.2*3.1*3.6m

-

Voltage:

-

380V/ 50Hz 3P+N+E (alterable)

Quick Details

-

Distance between Tie Bars(Width)(mm):

-

1350mm

-

Distance between Tie Bars(Height)(mm):

-

1280mm

-

Mold Height(mm):

-

600 - 1400 mm

-

Ejector Stroke(mm):

-

220 mm

-

Ejector Force(kN):

-

280 kN

-

Theoretical Shot Volume(cm³):

-

9000 cm³

-

Injection Rate (g/s):

-

1192 g/s

-

Injection Weight (g):

-

8100 g

-

Screw Speed (rpm):

-

1 - 100 rpm

-

Screw diameter (mm):

-

135 mm

-

Screw L/D Ratio:

-

22.3

-

Distance between Tie Bars:

-

1350*1280 mm

-

Weight (KG):

-

76000 kg

-

Place of Origin:

-

Jiangsu, China

-

Open Stroke(mm):

-

1400 mm

-

Model Number:

-

BST-13000A

-

Brand Name:

-

BST MACHINE

-

Power (kW):

-

245 kW

-

Product name:

-

car bumper making machine

-

Machine weight:

-

76t

-

Oil tank capacity:

-

2400L

-

Screw Diameter:

-

38-40mm

-

Name:

-

car bumper moulding machine

-

Keyword:

-

car bumper injection moulding machine

-

Injection pressure:

-

166Mpa

-

MACHINE DIMENSION:

-

13.2*3.1*3.6m

-

Voltage:

-

380V/ 50Hz 3P+N+E (alterable)

automatic wholesale Automatic Plastic Chair Car bumepr,Injection Molding Machine

Product Description

BEST13000A

Strong Technical design ability, Stable quality, and large production capability, Famous brand.

CONTROL SYSTEM

All-digital control system uses dedicated controller, multiple CPU processing division,

a multi-functional automatic fault detection, alarm system, certificates 99 mold of

processing procedures, with remote control interface. System is of high stability and

responsiveness. System uses color LCD, man made interface for easy operation and

with a number of peripheral interfaces.

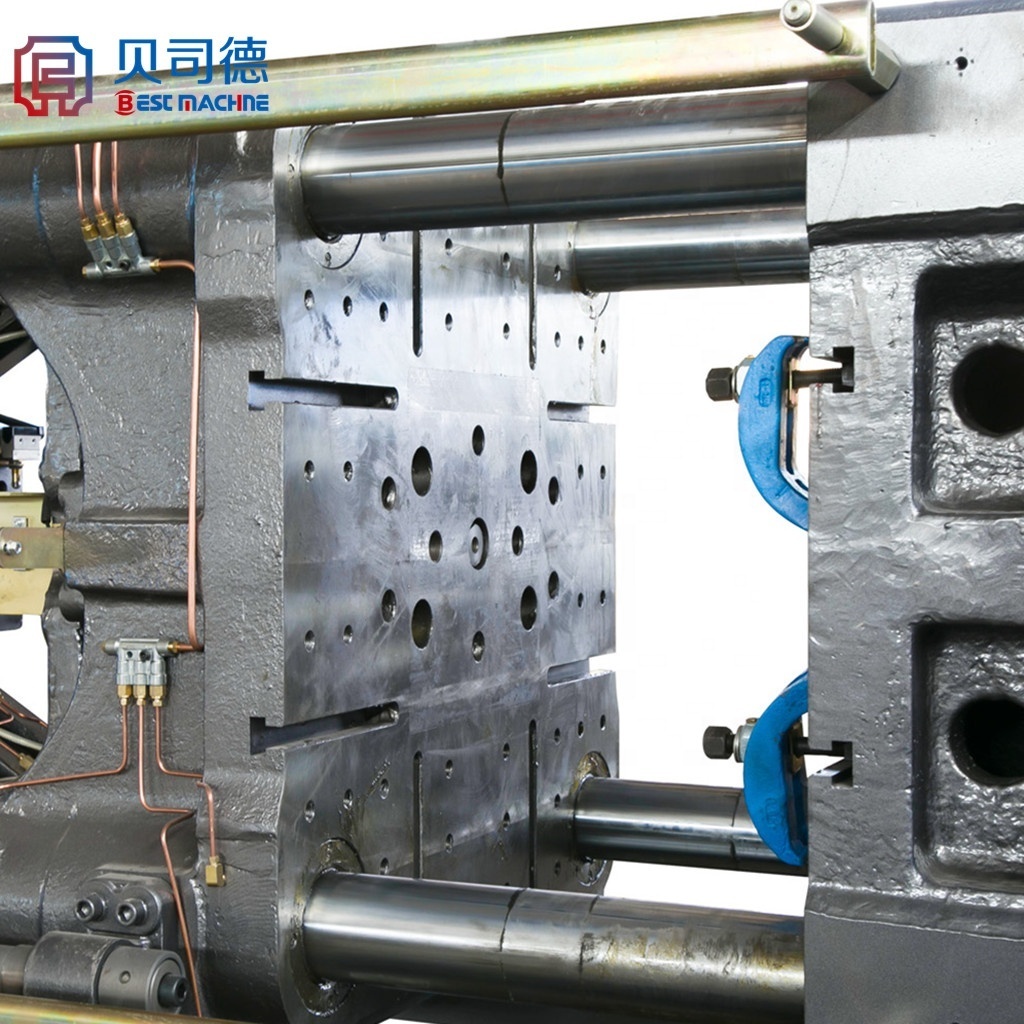

HYDRAULIC SYSTEM

Advanced hydraulic system design, through proportional control of pressure, flow achieves rapid multi-level pressure, speed switching, the system configuration is reasonable, stable and reliable. The noise is less than 75 dB. The medium and large machine adopts a two-way cartridge inserted valve system to improve the system of flow and speed of response, and makes the whole machine reach the best performance.

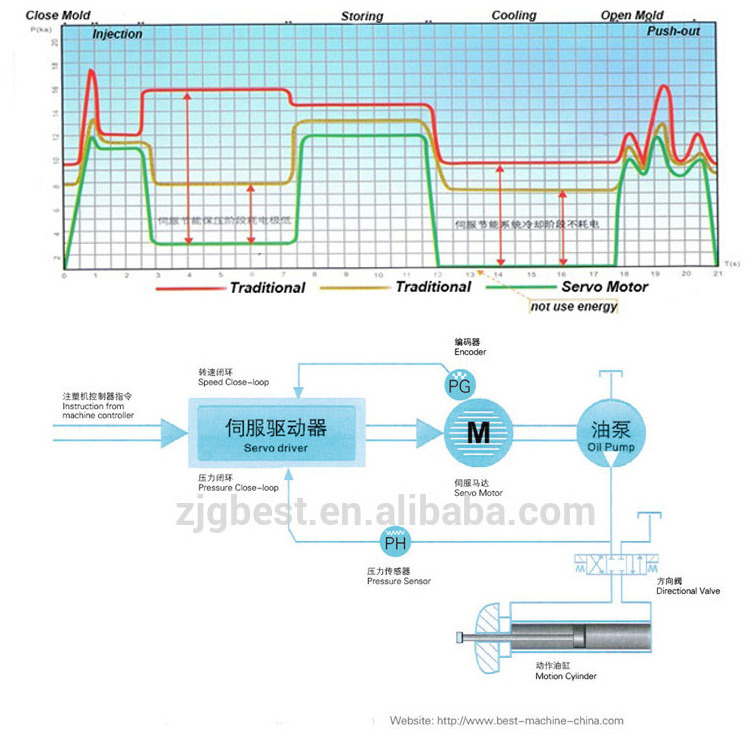

SERVO SYSTEM

After receiving the pressure and flow instruction from computer controller, the servo driver will compare it with the actual pressure and flow feedback, and rectify the difference the rotating speed of the servo motor. in this way , the control of injection moulding is not only acurate but also fast, and the repeatability of the products high as well.

Technical parameters

| Model | Clamp tonnage (KN) | Ejector tonnage (KN) | Heat power(KN) | Max.Pump pressure (MPA) | Pump motor power(kw) | Machine dinension(m) | Machine weight(t) | Oil tank capacity(L) |

| BST-1000A | 1000 | 50 | 7.6 | 16 | 11 | 4.3*1.5*1.6 | 3.4 | 180 |

| BST-1320A | 1320 |

50

|

8.2 | 16 | 13 | 4.5*1.6*1.7 | 3.9 | 200 |

| BST-1400A | 1400 | 50 | 8.2 | 16 | 13 | 4.8*1.6*1.7 | 4.2 | 220 |

| BST-1650A | 1650 | 70 | 8.2 | 16 | 15 | 5.0*1.6*1.7 | 5 | 250 |

| BST-1800A | 1800 | 70 | 11 | 16 | 15 | 5.3*1.6*1.75 | 5.5 | 250 |

| BST-2050A | 2050 | 70 | 11.6 | 16 | 17 | 5.4*1.6*1.75 | 6 | 270 |

| BST-2300A | 2300 | 70 | 11.6 | 16 | 18.5 | 5.7*1.8*2.0 | 6.5 | 300 |

| BST-2600A | 2600 | 70 | 15.5 | 16 | 25 | 6.1*1.7*1.8 | 8 | 350 |

| BST-3000A | 3000 | 80 | 15.5 | 16 | 25 | 6.5*1.8*1.8 | 9 | 370 |

| BST-3400A | 3400 | 80 | 17.5 | 16 | 30 | 6.7*2.0*1.9 | 10.8 | 400 |

| BST-3850A | 3850 | 80 | 17.5 | 16 | 30 | 7.0*2.2*2.0 | 11.5 | 400 |

| BST-4500A | 4500 | 85 | 20.5 | 16 | 37 | 7.3*2.3*2.4 | 13.8 | 450 |

| BST-4800A | 4800 | 125 | 23.4 | 16 | 40 | 8.3*2.2*2.2 | 16.2 | 600 |

| BST-5200A | 5200 | 125 | 28.1 | 16 | 43.5 | 8.6*2.2*2.25 | 20 | 750 |

| BST-5800A | 5800 | 125 | 28.1 | 16 | 48.5 | 8.75*2.2*2.3 | 21.8 | 850 |

| BST-6500A | 6500 | 160 | 37.1 | 16 | 55 | 9.2*2.2*2.4 | 26 | 1000 |

| BST-7500A | 7500 | 180 | 40.9 | 16 | 67 | 10.7*2.3*2.7 | 38 | 1200 |

| BST-8500A | 8500 | 186 | 42.5 | 16 | 74 | 11*2.4*2.75 | 45 | 1300 |

| BST-11000A | 11000 | 210 | 63 | 16 | 128 | 14*2.9*4.1 | 63 | 1800 |

| BST-13000A | 13000 | 280 | 85.25 | 16 | 160 | 13.2*3.1*3.6 | 76 | 2400 |

Hot Searches