- Product Details

- {{item.text}}

Quick Details

-

Weight:

-

13000 kg

-

Place of Origin:

-

Anhui, China

-

Power:

-

30kw

-

Dimension(L*W*H):

-

12m*5.5m*1.5m

-

Sheet Thickness (mm):

-

0.5-1.2

-

After-sales Service Provided:

-

Engineers available to service machinery overseas

-

Machine Type:

-

cnc duct making machine

-

Name:

-

U shape auto duct line 5

-

Keyword:

-

duct production line

-

Voltage:

-

220V/380V/415V/440V/customized

-

Company:

-

Nanjing RONGWIN Machinery Technology co.,ltd

-

color:

-

Customer Choose

Quick Details

-

Marketing Type:

-

Hot Product 2022

-

Brand Name:

-

RONGWIN

-

Condition:

-

New

-

Weight:

-

13000 kg

-

Place of Origin:

-

Anhui, China

-

Power:

-

30kw

-

Dimension(L*W*H):

-

12m*5.5m*1.5m

-

Sheet Thickness (mm):

-

0.5-1.2

-

After-sales Service Provided:

-

Engineers available to service machinery overseas

-

Machine Type:

-

cnc duct making machine

-

Name:

-

U shape auto duct line 5

-

Keyword:

-

duct production line

-

Voltage:

-

220V/380V/415V/440V/customized

-

Company:

-

Nanjing RONGWIN Machinery Technology co.,ltd

-

color:

-

Customer Choose

Products Description

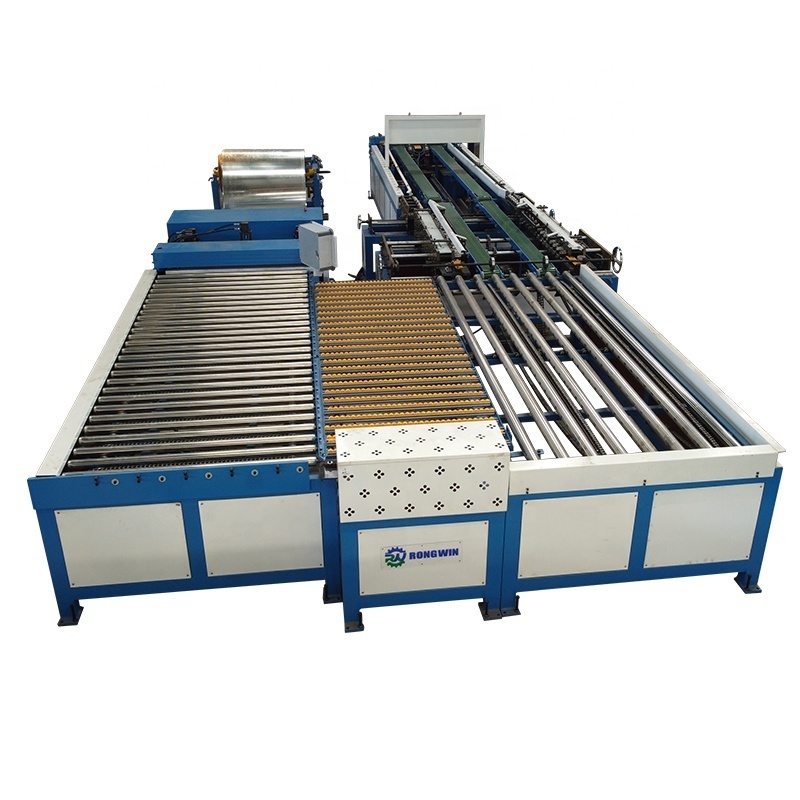

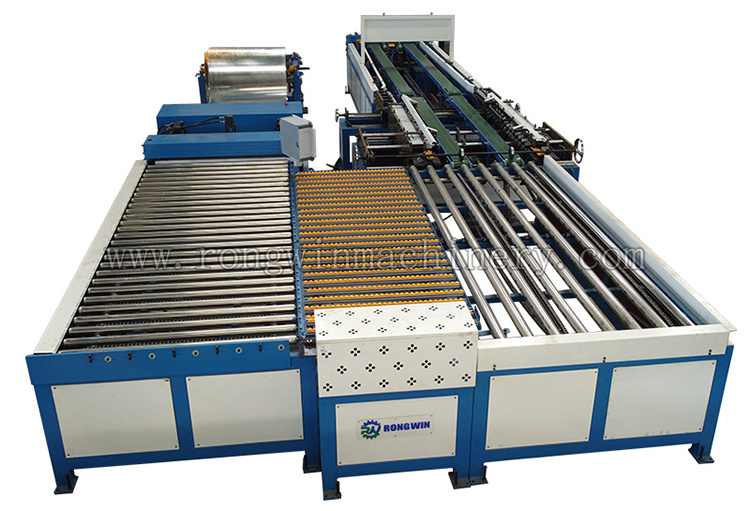

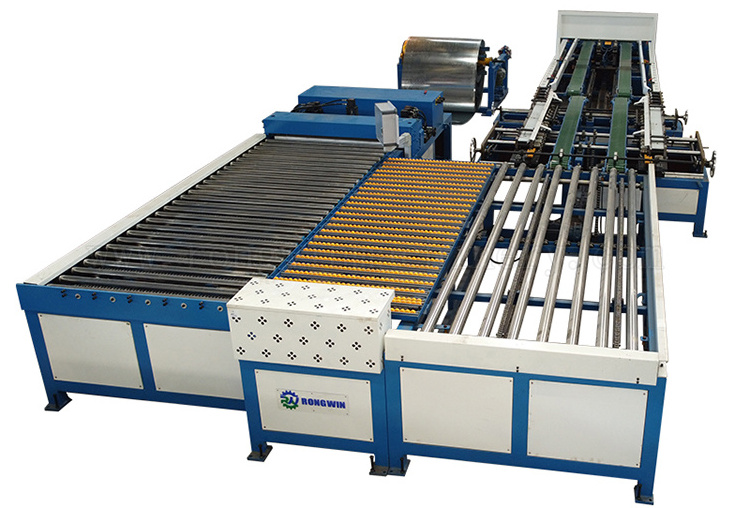

RONGWIN High Practical Automatic Pipe Making Machine for air tube forming Auto Production U Shape line 5

Function:

It's mainly for TDF / angle steel / C-shaped flange forming with daily processing capability of 800-2500 square meters. Only with inputting dimensions in duct, production line can automatically complete uncoiling, leveling,beading, punching, shearing, locking, forming TDF /angle steel / C-shaped flange and folding.

Our Advantages

· During feeding mechanism with pneumatic servo manipulator helps to ensure stability and speed of the machine, and the accuracy of its locating system.

· It only takes 20-25 seconds to make one L-shaped workpiece and the efficiency will double comparing with the linear type.

· Without moving back and forth the fixed locking machine is able to improve the efficiency.

· All the rolling reels are made of bearing steel so that the lifetime prolongs by more than 5 times.

· Under the material-saving mode of CNC system, waste is less than 20 mm per roll.

· With production memory functions, the production orders can be tracked and checked.

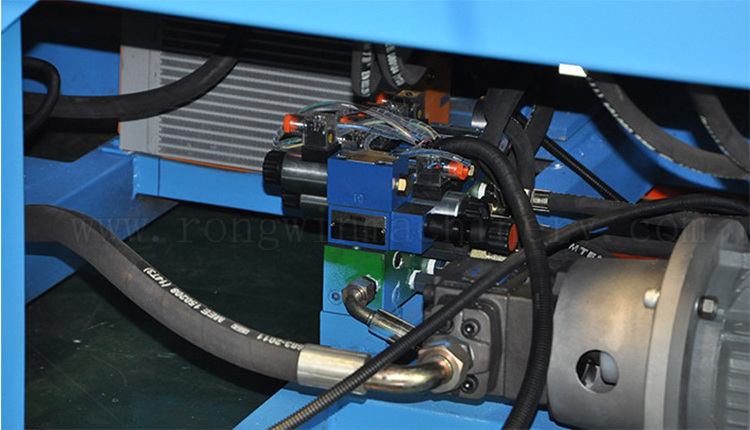

Detailed Images

Basic Configuration:

· One set of electric coil cradles, 4 material trays

· One set of rack

· One host (line 2 host)

· No.1 conveying platform

· One set of fixed joint locking machine

· No.2 conveying platform

· One set of duplex TDF flange forming machine

· One set of duplex angle steel flange forming machine

· One set of servo feeding platform

· One set of hydraulic folding machine

· One set of computer controlling system

Product real shot display

Machine parameters

|

Quantity(Sets)

|

1-5

|

>5

|

|

Est. Time(days)

|

30

|

Negotiable

|

Hot Searches