- Product Details

- {{item.text}}

Quick Details

-

Place of Origin:

-

Guangdong, China

-

Brand Name:

-

LC

-

Weight:

-

335 KG

-

Certification:

-

CE

-

Name:

-

manual carousel screen printing machine

-

Max Printing area:

-

450*650mm

-

Size of workbench:

-

500*700mm

-

Max height of screen frame:

-

40mm

-

Max printing speed:

-

1000pc/hr

-

Max printing thickness:

-

20mm

-

Drying mode:

-

IR

-

HS CODE:

-

8443192190

-

Marketing Type:

-

Hot Product 2019

Quick Details

-

Condition:

-

New

-

Color & Page:

-

Multicolor

-

Voltage:

-

220v

-

Place of Origin:

-

Guangdong, China

-

Brand Name:

-

LC

-

Weight:

-

335 KG

-

Certification:

-

CE

-

Name:

-

manual carousel screen printing machine

-

Max Printing area:

-

450*650mm

-

Size of workbench:

-

500*700mm

-

Max height of screen frame:

-

40mm

-

Max printing speed:

-

1000pc/hr

-

Max printing thickness:

-

20mm

-

Drying mode:

-

IR

-

HS CODE:

-

8443192190

-

Marketing Type:

-

Hot Product 2019

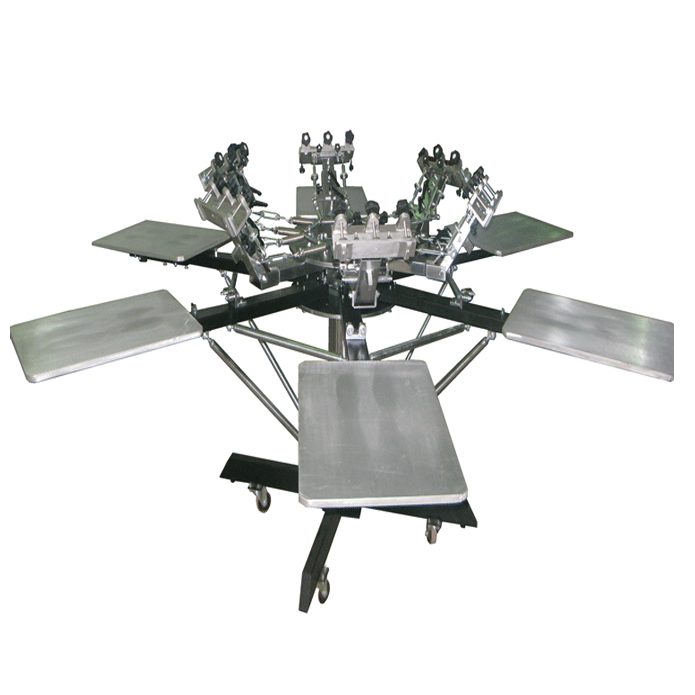

Screen printing on fabrics occupies a high market share, but there are still many differences between screen printing on fabrics and screen printing on general paper, plastic and other rigid products. For manual printing machines, understand the following knowledge points Very important:

1) The rotary-type printing machine for fabrics is actually the best design for the operator;

2) The working table is rarely used as an air-breathing type, because the fixing of the cloth requires glue such as table glue;

3) The types of inks for fabrics are very complicated, and the deployment requires special experience and technology;

4) You need to hold a squeegee with a handle to print;

5) You must understand and make screens that conform to the cloth printing process, which is another specialized technique;

6) You must also pay attention to the drying of the ink. The printing machine itself will have a swing drying oven, and you must also consider whether it is equipped with a dedicated tunnel drying line.

Manual printing machines are simple to operate, but labor-intensive. After you master the basic operating skills, upgrading to automatic printing machines is an inevitable direction.

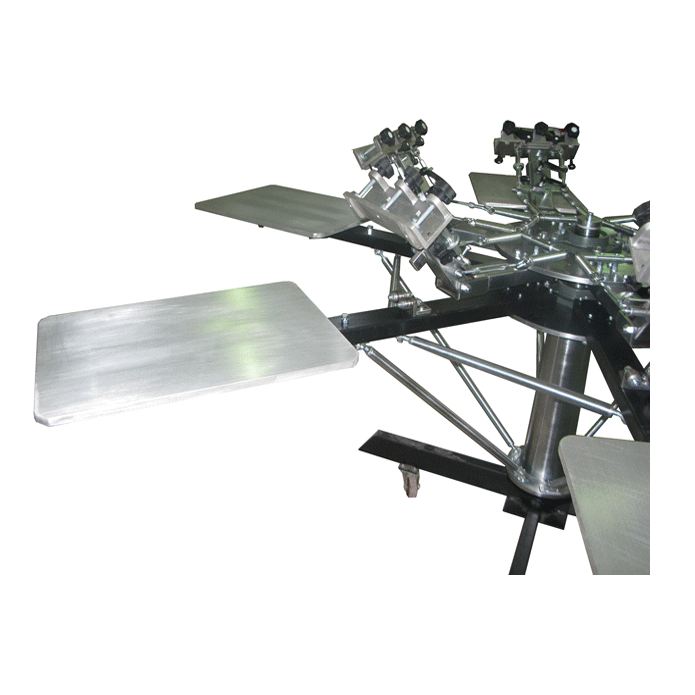

1.Max printing thickness:0-20 MM;

2.Net weight: 560KG;

3.Max printing area:450X650mm

4.Size of working table: 500×700mm;

5.Max printing speed:1000Pcs/H.

6.Printing number: 6;

7.Drying mode: IR;

8.Max height of screen frame: 40mm;

9. Max size of screen frame: 550*680mm;

10. Wattage of heater: 3.6KW.

Performance:

1. Operated by hand, controllable is well;

2. Have take place since the lock mechanism, accurate positioning, set-bit precision can reach 0.025mm;

3. Center vertical shaft structure design, smooth rotation, lightweight and comfortable, greatly reduce the labor intensity of the operator;

4. Screen rotation arrangement, the operator independent of each other and co-ordination, printing and high efficiency.

5. Screen frame can be adjustable according to diffrent objects to be printed.

6. Screen frame can be rise up after printing so that printing quality.

7. High-stabilization working table ensure non-shaking when printing .

8. IR Dryer with machine make the clothes drying fast.

Printing Factors

* 6 pcs Screen plates;

* Solven-base or Water-base table glue;

* 6 pcs Handle-scraper;

* Heat-set ink 6 colours.

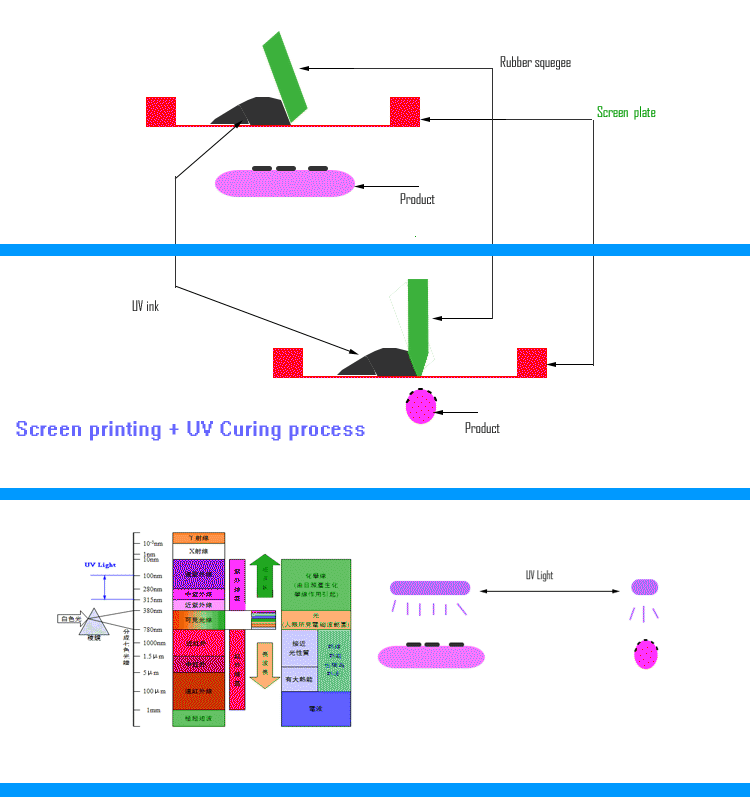

1. What is a screen printer ?

Screen printing machine uses rubber squeegee to apply pressure on the ink on the screen plate. the pattern is transferred onto the product through the hollow area. It is the most widely used special printing equipment in the industrial field. It is also the most compatible printing equipment for products materials.

The UV screen printing process is also a relatively common silk printing process. When using UV inks instead of ordinary dry inks, you need to choose a UV curing machine or LEDUV curing machine to achieve this process.

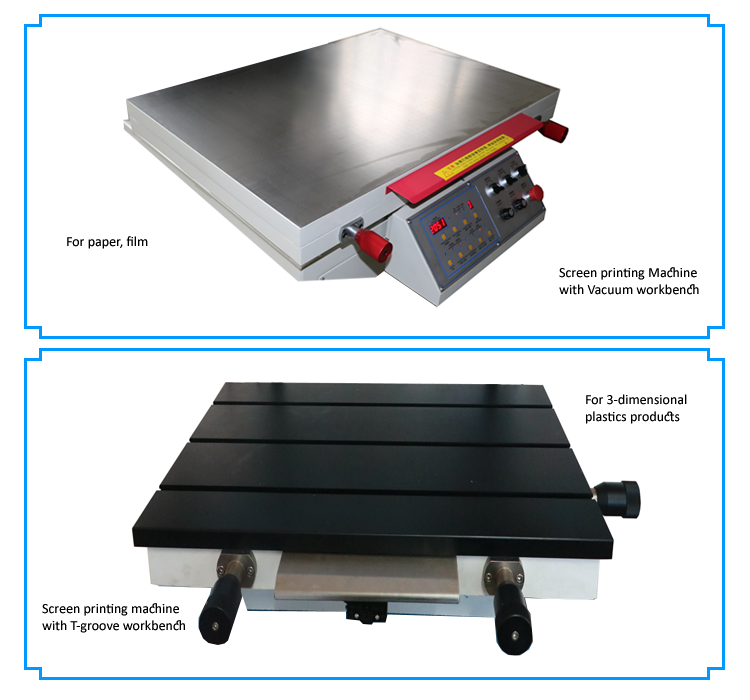

2 . The difference between the Vacuum table screen printer and T -shaped screen printer

The products involved in the plane screen printer are generally divided into two types. One is relatively thin and thinner products, such as paper, film, and general workbenches that need to be inhaled. They will be adsorbed when printing , for a product with a certain shape and quality. You can choose a T -shaped screen printer, which usually makes a fixture to fix. Automatic silk printing opportunities connect to automatic feed mechanisms and unloading mechanisms to achieve the automation of screen printing.

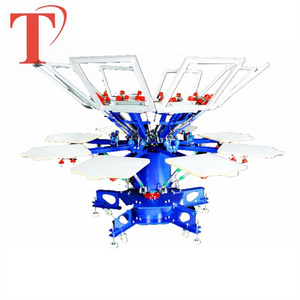

3. Shuttle screen printer and Turntable screen printer

The limitations of the single workplace screen printer are very obvious, it is necessary to wait for one product to complete the screen printing before the other product can be placed. The production efficiency is affected. Like the pad printer, the screen printer can also install the shuttle workbench and the turntable workbench. There are two structures, front and rear movements and left and right movement, which are generally large -sized; turntable screen printers are relatively popular screen printers. During the silk seal period, stations continued to rotate, saving working time, and improved production efficiency. The turntable screen printer is generally suitable for products with smaller size.

4. Screen printing machine operating system

The ordinary screen printing machine adopts the microcomputer control system to carry on the control, the high-end screen printing machine uses the PLC to carry on the control, specially the servo control system screen printing machine or the automatic screen printing machine, uses the PLC control system quite commonly because it need more parameter setting during screen printing.

5. How to evaluate the quality of the screen printer

Screen Printing machine technology content is low, more and more enterprises began to produce and sell screen printing machines, screen printing machines of uneven quality, how to evaluate the quality of screen printing machine is essential. As the majority of brand-name screen printing machine is not sold through the network, so, through Alibaba sales of screen printing machines are not high end screen printing machine.

1) Design of the factory means: a special design department of the enterprise quality is more reliable. China has 70% of the screen printing machine manufacturing enterprises and no special design department, the development of new products on-site assembly by the basic, which is extremely adverse to the standardization of production machinery;

2) Processing means: CNC processing costs are higher, but the parts manufactured high precision; visit the factory must inspect whether the factory has CNC machining capacity;

3) Materials Selection: Material selection is very important. Now fierce competition, the vast majority of domestic factories in the selection of the above efforts, only the brand enterprises are willing to insist on the selection criteria above;

7. What is screen plate of screen printer?