- Product Details

- {{item.text}}

Quick Details

-

Model Number:

-

LK-MLS

-

process:

-

Electroplated

-

Diameter:

-

125mm-300mm

-

hole:

-

16 25.4 25 50 mm

-

thickness:

-

10-300mm

-

type:

-

as you require

-

griniding object:

-

marble ,granite ,glass

-

Feature:

-

High Speed.Straight Smooth Edge

-

Material:

-

Diamond + Metal Powder

-

Package:

-

Carton Box

-

Machine:

-

CNC edge grinding machine

Quick Details

-

Type:

-

diamond wheel

-

Place of Origin:

-

Hubei, China

-

Brand Name:

-

LK

-

Model Number:

-

LK-MLS

-

process:

-

Electroplated

-

Diameter:

-

125mm-300mm

-

hole:

-

16 25.4 25 50 mm

-

thickness:

-

10-300mm

-

type:

-

as you require

-

griniding object:

-

marble ,granite ,glass

-

Feature:

-

High Speed.Straight Smooth Edge

-

Material:

-

Diamond + Metal Powder

-

Package:

-

Carton Box

-

Machine:

-

CNC edge grinding machine

Diamond grinding disc for glass ,Marble, ceramic

Feature

1 .LK diamond grinding wheel is designed to grind special shape of glass edge used on building glass,automotive glass,furniture glass,electrical information and optical glass etc.

2. LK diamond grinding wheel is designed to grind special shape of Marble and ceramic

3.Efficient for trimming & grinding and shaping stone products.

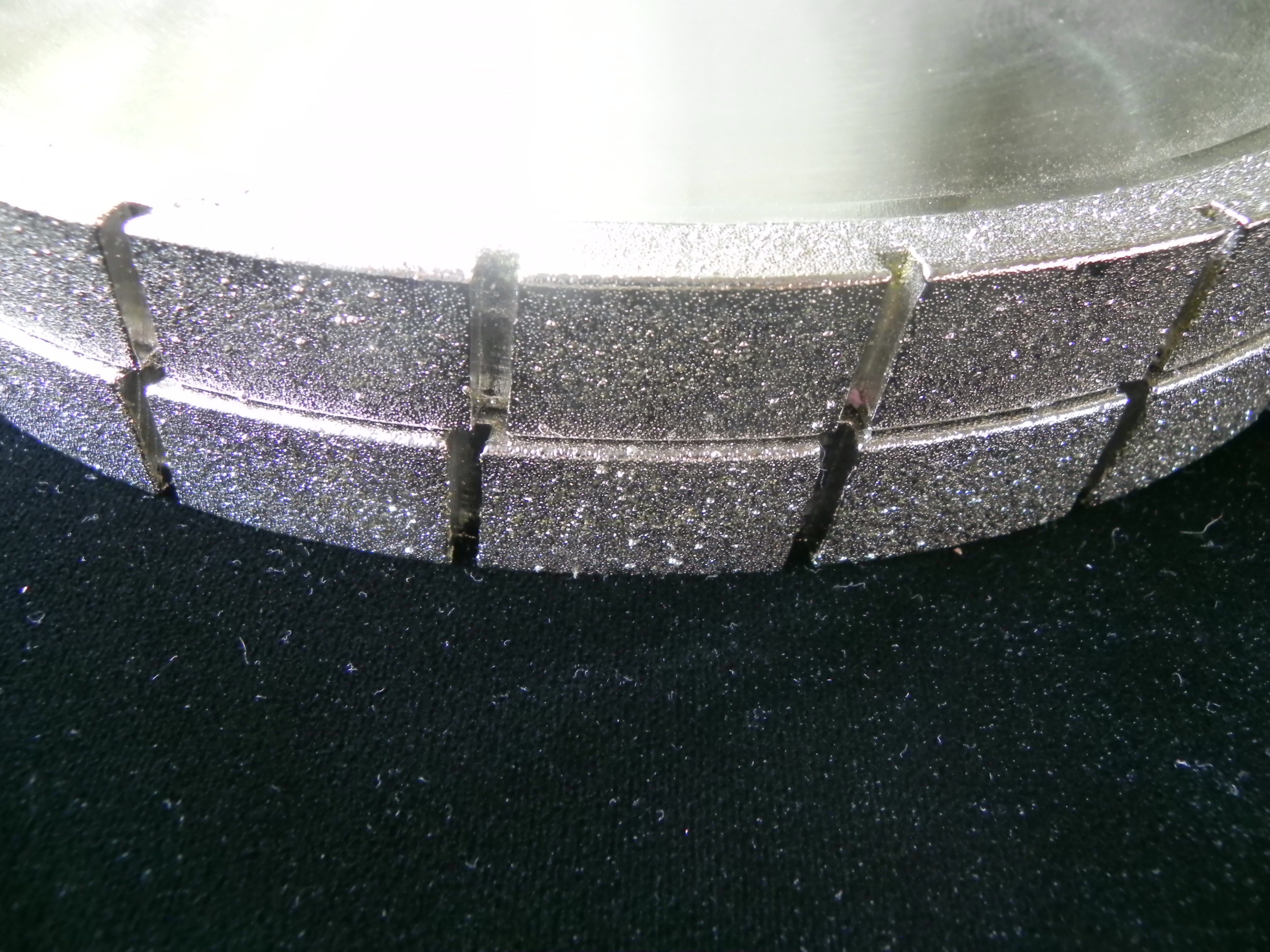

4.Good material,high content of diamond.

5. Each of LK New kinds of Diamond grinding wheel have been tested before launching it in the market

6.Our diamond grinding wheel have all kinds of Type, and competitive price

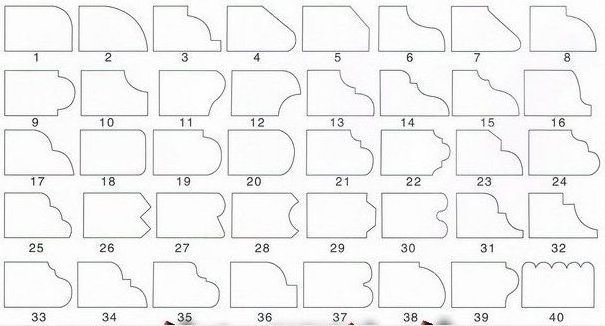

Drawing

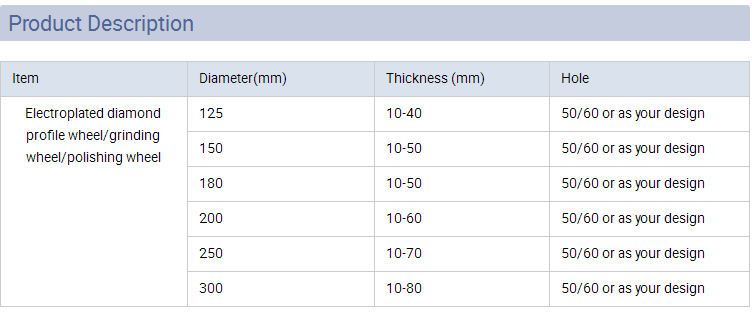

Electroplated diamond grinding /polishing wheel for stone,marble,granite,concrete,asphalt ,fiber glass ,ect.

Q1. Are you a manufacturer?

Yes. We have been a manufacturer of diamond products for over 17 years. We own our factory.

Q2. What do you mainly produce?

Our main products cover diamond saw blade, diamond grinding wheel, diamond polishing pad.

diamond drill bit

Q3. What is the difference between Electroplated and Sintered ?

Electroplated diamond tools have a single layer of diamond held onto the tool with a layer of nickel that is grown over the diamond in a plating tank. Once that layer of diamond is worn down, the tool is used up and it is time to purchase a new tool.

Sintered diamond tools , on the other hand, have diamond impregnated throughout the entire metal structure of the grinding part of the tool. Once a layer of diamond is worn down, you can use a dressing stick to drill, slice, or grind into and it will remove the topmost layer of diamond and expose new diamonds below. It becomes like a brand new tool!

Q4. What information should be provided if I want to get a quotation?

- Product specification(diameter, bore diameter, width, thickness, height )

- Process: electroplated, sintered or vacuum brazed

- Product application

- Drawings or pictures

- Diamond grit

- Quantity

Q5. Why should I choose you?

- We have rich experience in handling orders for heavy buyers with professional process

- stable raw material purchasing

- Favorable orders follow -up management

- laudable lead -time &shipment countrol

- Traceable quality evaluation

- Flexible payemnt terms

-

Remarkable after -sale service