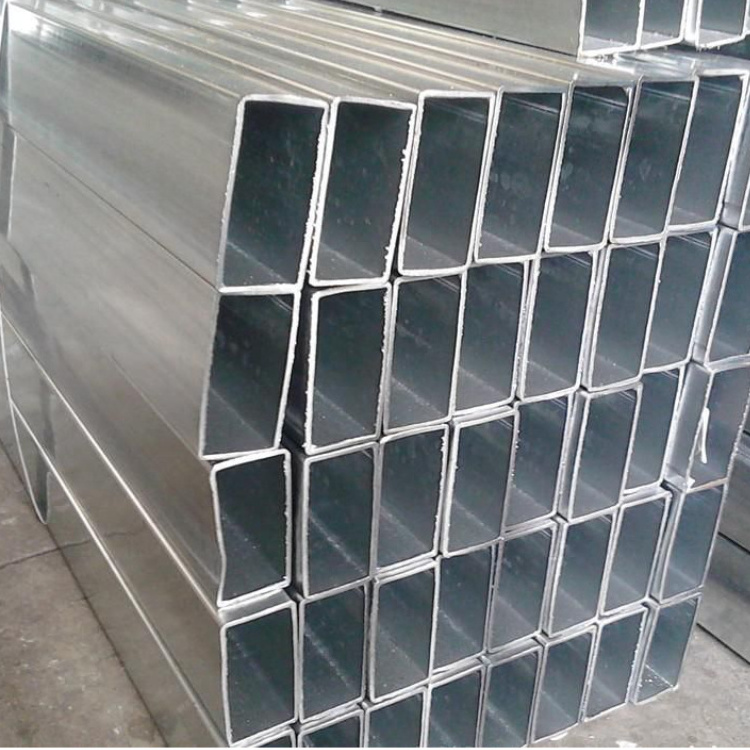

* Process:

Pre-galvanized steel pipes are galvanized before they are formed into the final product. The galvanization process

typically involves coating the steel with a layer of zinc through either a hot-dip process or an electroplating process.

* Appearance:

Pre-galvanized pipes have a smoother and more even zinc coating. The surface is usually shinier and has a uniform appearance.

* Application:

Pre-galvanized pipes are often used in applications where the final appearance is important, such as in outdoor structures, fencing, and decorative applications.

- Product Details

- {{item.text}}

Quick Details

-

Oiled or Non-oiled:

-

Non-oiled

-

Invoicing:

-

by actual weight

-

Place of Origin:

-

China

-

Thickness:

-

0.7mm~6mm, Request

-

Grade:

-

Q195/Q215/Q235/Q345

-

Delivery Time:

-

3-30days

-

Product name:

-

Welded Steel Pipe

-

Type:

-

Straight Seam

-

Surface:

-

Zinc Coating

-

Shape:

-

Square. Rectangular.Round

-

Material:

-

Carbon Steel Grade B

-

Keyword:

-

Galvanized SHS

-

Usage:

-

Building Construction

-

Packing:

-

Sea Worthy Packing

Quick Details

-

Section Shape:

-

Square

-

Surface Treatment:

-

Hot Rolled

-

Tolerance:

-

±1%

-

Oiled or Non-oiled:

-

Non-oiled

-

Invoicing:

-

by actual weight

-

Place of Origin:

-

China

-

Thickness:

-

0.7mm~6mm, Request

-

Grade:

-

Q195/Q215/Q235/Q345

-

Delivery Time:

-

3-30days

-

Product name:

-

Welded Steel Pipe

-

Type:

-

Straight Seam

-

Surface:

-

Zinc Coating

-

Shape:

-

Square. Rectangular.Round

-

Material:

-

Carbon Steel Grade B

-

Keyword:

-

Galvanized SHS

-

Usage:

-

Building Construction

-

Packing:

-

Sea Worthy Packing

Product Description

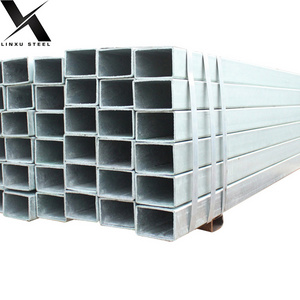

PRE-GALVANIZED STEEL SQUARE/

RECTANGLE

TUBE

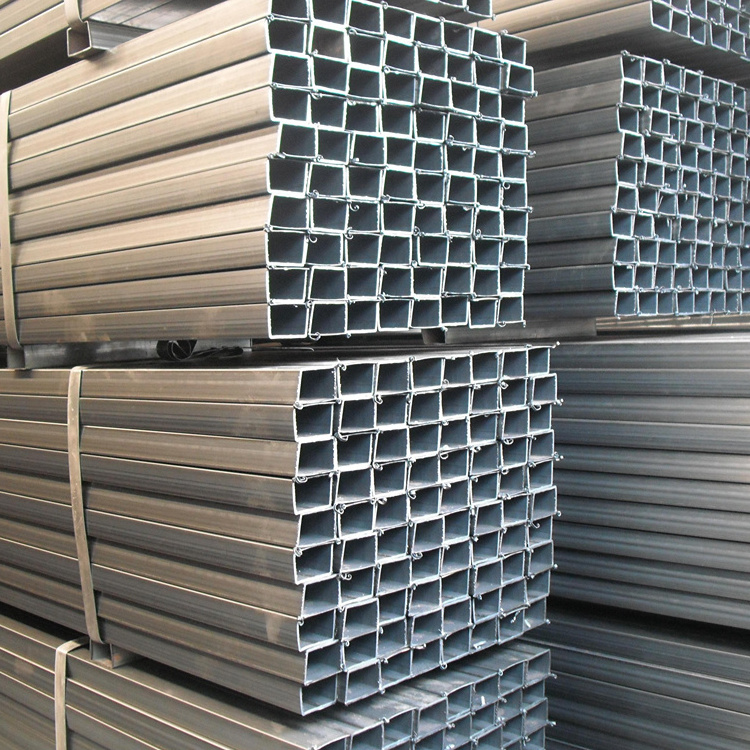

HOT-DIP STEEL SQUARE/RECTANGLE TUBE

* Process:

Hot-dip galvanized steel pipes are formed first and then immersed in a molten bath of zinc. The immersion process results in a thicker and more durable zinc coating compared to pre-galvanized pipes.

* Appearance: Hot-dip galvanized pipes may have a rougher surface compared to pre-galvanized pipes due to the thicker zinc coating. The coating is usually more uneven, but it provides greater protection against corrosion.

* Application: Hot-dip galvanized pipes are commonly used in applications where corrosion resistance is a critical factor, such

as in water pipelines, construction, and outdoor structures exposed to harsh environments.

* Appearance: Hot-dip galvanized pipes may have a rougher surface compared to pre-galvanized pipes due to the thicker zinc coating. The coating is usually more uneven, but it provides greater protection against corrosion.

* Application: Hot-dip galvanized pipes are commonly used in applications where corrosion resistance is a critical factor, such

as in water pipelines, construction, and outdoor structures exposed to harsh environments.

Our Advantange:

1.100% after-sales quality and quantity assurance.

2. Professional sales manager quickly reply within 24 hours.

3. Large Stock for regular sizes.

4. Free sample 20cm high quality.

5. Strong produce capability and capital flow.

Strict Quality Control:

1) During and after production, 4 QC staffs with more than 5 years experience inspect products in random.

1) During and after production, 4 QC staffs with more than 5 years experience inspect products in random.

2) National accredited laboratory with CNAS certificates

3) Acceptable inspection from third party appointed/paid by buyer, such as SGS, BV.

4) Approved by Malaysia, Indonesia, Singapore, Philippines, Australia, Peru and UK.

3) Acceptable inspection from third party appointed/paid by buyer, such as SGS, BV.

4) Approved by Malaysia, Indonesia, Singapore, Philippines, Australia, Peru and UK.

If you have any special specification, please message us directly.

|

COMMODITY NAME

|

Square and Rectangular Hollow Section Welded Steel Pipe

|

|

|

|

|

SIZE RANGE

|

20x20MM-600x600MM ; THICKNESS: 0.70MM--20.0MM

|

|

|

|

|

MATERIAL GRADE

|

Q195 = S195 / A53 Grade A

Q235 = S235 / A53 Grade B / A500 Grade A / STK400 / SS400 / ST42.2 Q355 = S355JR / A500 Grade B Grade C |

|

|

|

|

STANDARD

|

ASTM A53 ( sch10; SCH40), ASTM A500, BS1387, EN39, BS1139, ISO65

GB/T3091, GB/T13793 |

|

|

|

|

Surface

|

1) Natural Black

2) Oiled 3) Color Painted 4) Galvanized (zinc coating 30-500g/m2) |

|

|

|

|

DELIVERY TIME

|

7-10 days after receiving advanced payment

|

|

|

|

|

Pre-galvanized

- Square and Rectangular Steel Pipe size chart

|

|

|

||

|

Square Hollow Section

|

Rectangular Hollow Section

|

Wall Thickness

|

||

|

15*15

|

10*20

|

0.7mm~1.5mm

|

||

|

20*20

|

/

|

0.7mm~2mm

|

||

|

25*25

|

20*30 15*30

|

0.7mm~2.3mm

|

||

|

30*30 40*40 50*50 60*60 80*80 50*100 100*100

|

20*40 30*40 35*55 30*50 30*60 37*57 37*77 40*60 40*80 50*70 60*80 60*120

|

0.7mm~2.5mm

|

||

|

37*37

|

27*47 25*50

|

0.7mm~2.3mm

|

||

|

If you have other specification request,please message us.

|

|

|

||

|

Hot Dip Galvanized

- Square and Rectangular Steel Pipe size chart

|

HOT DIP GALVANIZED-Square and Rectangular Steel Pipe size chart

|

|

|

|||

|

Square Hollow Section

|

Wall Thickness

|

Rectangular Hollow Section

|

Wall Thickness

|

|||

|

20*20

|

1.5mm~2mm

|

20*40

|

1.5mm~3mm

|

|||

|

25*25

|

1.5mm~2mm

|

30*40

|

1.5mm~3mm

|

|||

|

30*30

|

1.5mm~2.75mm

|

30*50

|

1.5mm~3.75mm

|

|||

|

40*40

|

1.5mm~3.75mm

|

40*60

|

1.5mm~3.75mm

|

|||

|

50*50

|

1.5mm~3mm

|

40*80

|

1.5mm~4.75mm

|

|||

|

60*60

|

2.5mm~3.75mm

|

50*70

|

1.5mm~3.75mm

|

|||

|

80*80

|

1.7mm~4.75mm

|

50*100

|

1.5mm~5.75mm

|

|||

|

100*100

|

1.7mm~4.75mm

|

|

|

|||

|

120*120

|

2.5mm~5.75mm

|

|

|

|||

|

150*150

|

2.5mm~7.75mm

|

|

|

|||

|

200*200

|

2.5mm~9.75mm

|

|

|

|||

|

If you have other specification request,please message us.

|

|

|

|

|||

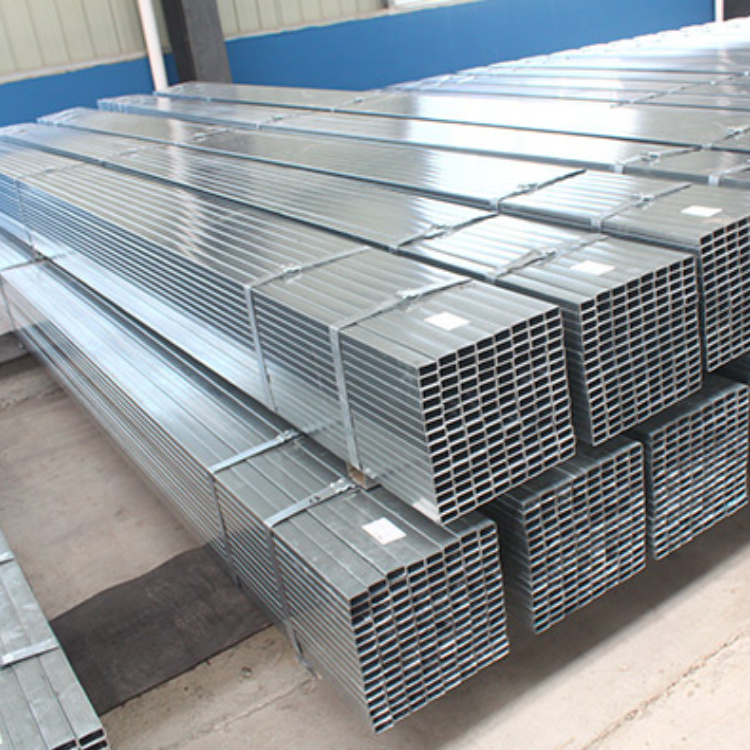

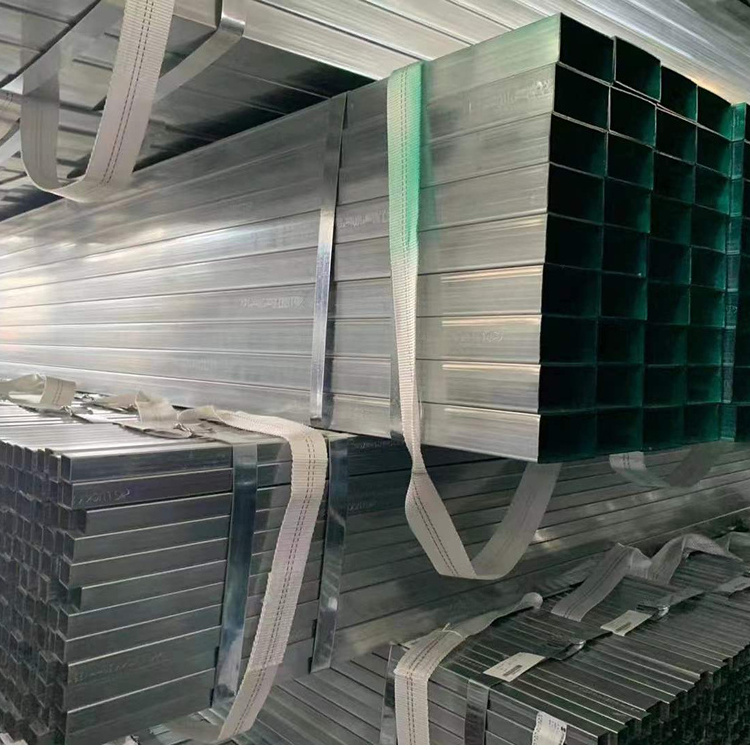

galvanized square steel tube

A galvanized square steel tube is a type of hollow structural section made from steel that has been coated with a layer of zinc through a process called galvanization. Galvanization involves applying a protective zinc coating to the steel to prevent corrosion and rust. This makes the steel more durable and resistant to the elements.

The square shape of the tube makes it suitable for various applications where square or rectangular profiles are needed, such as in construction, infrastructure, and manufacturing. Galvanized steel tubes are commonly used in outdoor and corrosive environments where the protective zinc coating helps extend the life of the material.

Here are some key features and applications of galvanized square steel tubes:

Corrosion Resistance: The zinc coating provides excellent corrosion resistance, making galvanized steel tubes suitable for outdoor applications and environments with high moisture levels.

Structural Strength: Galvanized square steel tubes are often used in structural applications due to their strength and durability.

Versatility: These tubes are versatile and find applications in various industries, including construction, fencing, handrails, agricultural equipment, and more.

Easy Fabrication: Galvanized steel tubes are relatively easy to work with, allowing for cutting, welding, and other fabrication processes.

Longevity: The galvanized coating enhances the lifespan of the steel, making it a cost-effective choice for projects that require durable materials.

Appearance: The galvanized coating gives the steel a characteristic silver-gray appearance.

Before using galvanized square steel tubes, it's essential to consider factors such as load-bearing requirements, environmental conditions, and the specific needs of the project. Additionally, proper handling and installation practices should be followed to maintain the integrity of the galvanized coating.

For galvanized square steel tubes, common specifications can vary based on different standards and requirements. Here are some typical specifications, but it's important to note that actual specifications may vary depending on the manufacturer, regional standards, and specific project needs:

Dimensional Specifications:

Outer Diameter: For example, 15mm, 20mm, 25mm, 50mm, etc.

Wall Thickness: For example, 1mm, 1.5mm, 2mm, etc.

Length: Typically measured in meters, such as 6 meters, 12 meters, etc.

Steel Grade or Material:

Q195, Q235, Q345, etc.: These are common steel grades representing different strengths and chemical compositions.

Zinc Coating Weight:

Usually measured in grams per square meter (g/m²) or ounces per square foot (oz/ft²): For example, 200g/m², 300g/m², etc.

Surface Treatment and Appearance:

Bright Surface, Aluminum Coating, etc.

Standards and Certifications:

ASTM A500, GB/T 6728-2002, etc.: These are standards related to square steel tubes, and the appropriate standard can be selected based on project requirements.

Details Images

Different Surfaces

Normal spangle

Through addition of certain heavy metal element into molten zinc bath, regular spangle pattern is produced on Hot-dip zinc-coated steel sheet.

Minimized spangle

The zinc layer(coating) does Not contain Lead(Pb), which complies with EU WEEE and RoHS directives. This is a non-toxic and environmental friendly material.

Spangle-free

During hot-dip galvanizing, only a certain amount of aluminum is added to the zinc solution, and lead-free, antimony, and tin are not added to produce spangle-free products.

Main Features of Galvanized Steel

Anticorrosive

: 13 years in heavy industrial areas, 50 years in the ocean, 104 years in the suburbs and 30 years in cities.

Cheap : The cost of hot-dip galvanizing is lower than that of other coatings.

Reliable : The zinc coating is metallurgically bonded to the steel and forms part of the steel surface,so the coating is more

durable.

Strong toughness : The galvanized steel sheet layer forms a special metallurgical structure that can withstand mechanical damage during transportation and use.

Comprehensive protection : Every part of the plated piece can be galvanized, and is fully protected even in depressions,sharp corners,and hidden places.

Save time and energy : Galvanizing process is faster than other coating methods.

Cheap : The cost of hot-dip galvanizing is lower than that of other coatings.

Reliable : The zinc coating is metallurgically bonded to the steel and forms part of the steel surface,so the coating is more

durable.

Strong toughness : The galvanized steel sheet layer forms a special metallurgical structure that can withstand mechanical damage during transportation and use.

Comprehensive protection : Every part of the plated piece can be galvanized, and is fully protected even in depressions,sharp corners,and hidden places.

Save time and energy : Galvanizing process is faster than other coating methods.

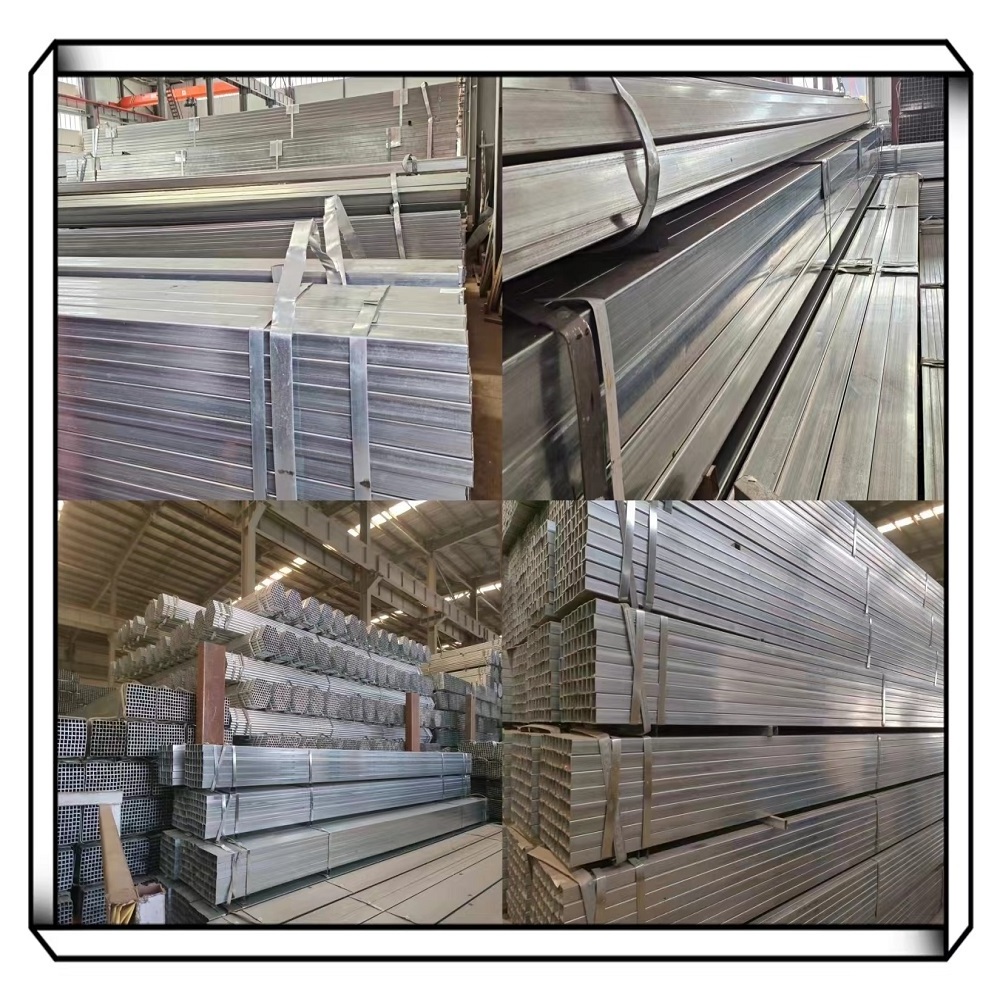

Company Introduction

Packing&Shipping

PACKING AND DELIVERY:

1. 25~28 tons/container and 5 tons/size for a trial order;

2. For 20" container the max length is 5.8m;

3. For 40" container the max length is 11.8m.

2. For 20" container the max length is 5.8m;

3. For 40" container the max length is 11.8m.

Related Products

FAQ

Q:Can you send samples?

A:Of course, we can send samples to all parts of the world, our samples are free, but customers need to bear the courier costs.

Q:What product information do I need to provide?

A:You need to provide the grade, width, thickness, coating and the number of tons you need to purchase.

Q:About product prices?

A:Prices vary from period to period due to cyclical changes in the price of raw materials.

Q:What are the certifications for your products?

A:We have ISO 9001, SGS, EWC and other certifications.

Q:How long does your delivery time take?

A:In general, our delivery time is within 7-10 days, and may be delayed if the demand is extremely large or special circumstances occur.

Q:Can I go to your factory to visit?

A:Of course, we welcome customers from all over the world to visit our factory.

Q:Does the product have quality inspection before loading?

A:All our products are strictly tested for quality before packaging, and unqualified products will be destroyed.

A:Of course, we can send samples to all parts of the world, our samples are free, but customers need to bear the courier costs.

Q:What product information do I need to provide?

A:You need to provide the grade, width, thickness, coating and the number of tons you need to purchase.

Q:About product prices?

A:Prices vary from period to period due to cyclical changes in the price of raw materials.

Q:What are the certifications for your products?

A:We have ISO 9001, SGS, EWC and other certifications.

Q:How long does your delivery time take?

A:In general, our delivery time is within 7-10 days, and may be delayed if the demand is extremely large or special circumstances occur.

Q:Can I go to your factory to visit?

A:Of course, we welcome customers from all over the world to visit our factory.

Q:Does the product have quality inspection before loading?

A:All our products are strictly tested for quality before packaging, and unqualified products will be destroyed.

Hot Searches