- Product Details

- {{item.text}}

Quick Details

-

Model Number:

-

YF17021B

-

Drawing Format:

-

2D/(PDF/CAD)3D(IGES/STEP)

-

Tolerance:

-

0.02mm -0.05mm

-

Feature:

-

Design optimization for the products

-

Color:

-

Customer's Request

-

Mold Life:

-

30000~1000000 Shots

-

Mould material:

-

P20/718/738/NAK80/S136/2738/2316

-

Plastic parts material:

-

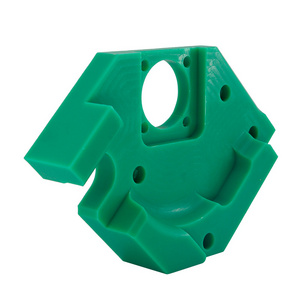

PP ABS PA POM PC PMMA PPS PEEK PPE SPS TPE TPU

-

Surface finish:

-

Custom Surface Texture

-

Product name:

-

Plastic Parts

-

Certification:

-

ISO9001:2015

Quick Details

-

Processing Service:

-

Injection molding production, Painting and assembly

-

Place of Origin:

-

Shenzhen

-

Brand Name:

-

YF

-

Model Number:

-

YF17021B

-

Drawing Format:

-

2D/(PDF/CAD)3D(IGES/STEP)

-

Tolerance:

-

0.02mm -0.05mm

-

Feature:

-

Design optimization for the products

-

Color:

-

Customer's Request

-

Mold Life:

-

30000~1000000 Shots

-

Mould material:

-

P20/718/738/NAK80/S136/2738/2316

-

Plastic parts material:

-

PP ABS PA POM PC PMMA PPS PEEK PPE SPS TPE TPU

-

Surface finish:

-

Custom Surface Texture

-

Product name:

-

Plastic Parts

-

Certification:

-

ISO9001:2015

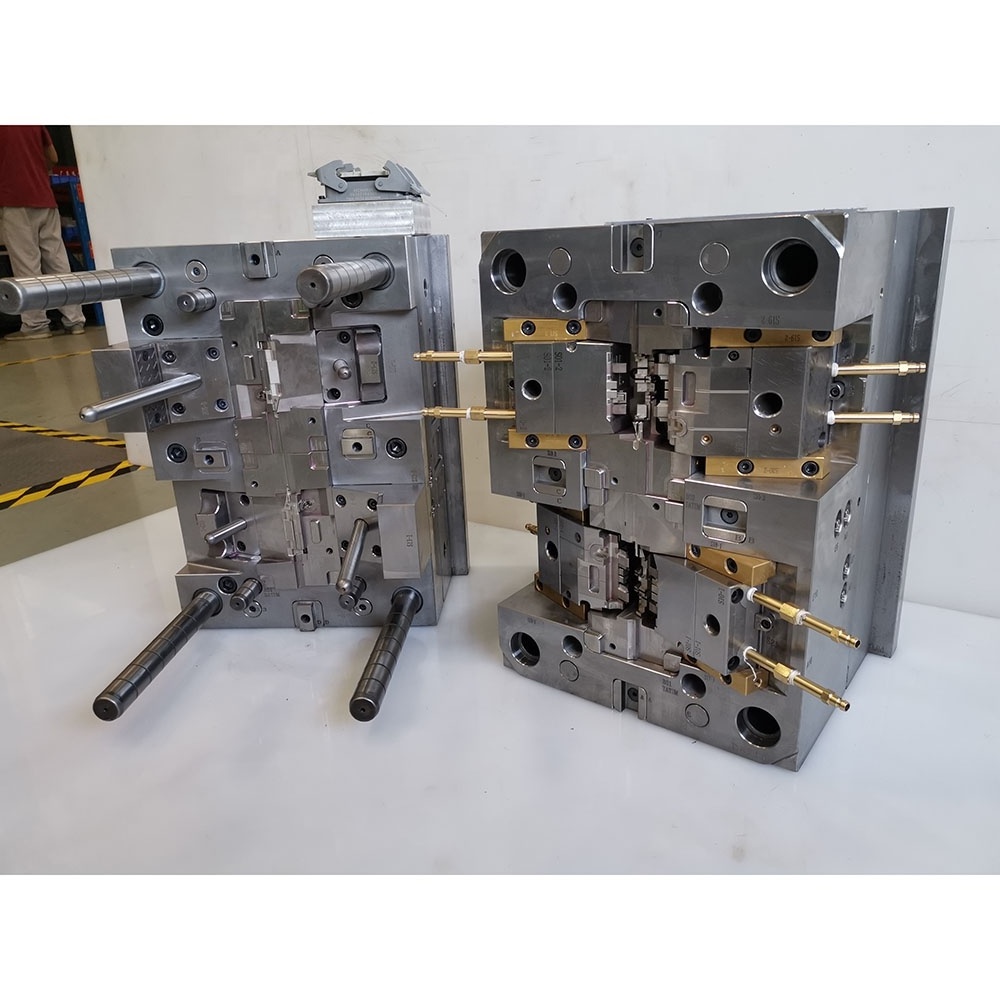

Plastic Injection molding service custom plastic parts

Product Description

Service include:Plastic part analysis and improvement

Mechanical design, Electronic design

Moldflow and mold design

Prototype mould

Injection mold making

Plastic parts molding production

Paiting, Printing, Assembly

Mechanical design, Electronic design

Moldflow and mold design

Prototype mould

Injection mold making

Plastic parts molding production

Paiting, Printing, Assembly

Mould Making Capabilities:

Plates and Mold Base Components: ± 0.013 mm (± 0.0005 in)

Cavity components: ± 0.005 mm (± 0.0002 in)

Cavity components: ± 0.005 mm (± 0.0002 in)

|

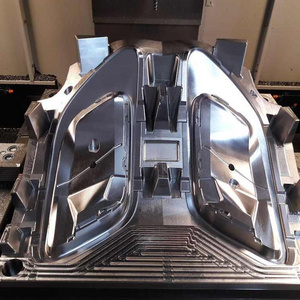

Application

|

Automotive, ATV, Mechanical equipment, Construction, Home appliance, Aviation,

Office facilities, Agriculture, etc. |

|

|

|

|||

|

Mold Base

|

LKM, HASCO, DME, etc.

|

|

|

|

|||

|

Mold Steel

|

NAK80, ASSAB8407, S136, 718H, 738H, etc.

|

|

|

|

|||

|

Mold Cavity

|

Single cavity mold or Multi cavities mold

|

|

|

|

|||

|

Tolerance

|

+/-0.005mm

|

|

|

|

|||

|

Surface Finish

|

Powder coating, Zinc coating, Galvanization, Electro-deposition coating, Chrome/zinc/nickel plating, Polishing, Silkscreen, Black oxide

|

|

|

|

|||

|

Sprue Gate

|

Hot runner, Cold runner, Tunnel gate, Pin point gate, sub-gate, etc.

|

|

|

|

|||

|

Product Resin

|

PC, ABS, PP, POM, PEEK, PPS, NYLON, PMMA, TPE, TPU, SAN, etc.

|

|

|

|

|||

|

Mold Life

|

100K - 1 million shots

|

|

|

|

|||

|

Process

|

Milling, Grinding, CNC machining, EDM Spark, Wire cut, Injection molding

|

|

|

|

|||

|

Certificate

|

ISO 9001:2015

|

|

|

|

|||

Company Introduction

YF mold has a series of advanced equipments including Fanuc CNC machines, Sodick EDM machines, Sodick wire cut machines, Okamoto grinding machines, Haitian Injection molding machines, Zeiss CMM, Easson 2D projector, and iMould Automatic System. We make full dimension measurements for all mould components, copper and parts.

Our Advantages

1. Own factory, ISO 9001 certified.

2. Build moulds in house and 80% of our businesses are export moulds.

3. The managements are technical people and always attach importance to quality and technological development.

4. YF has excellent advantage in Multi cavities moulds & Two shot moulds(with unscrew system)& insert molding with

2. Build moulds in house and 80% of our businesses are export moulds.

3. The managements are technical people and always attach importance to quality and technological development.

4. YF has excellent advantage in Multi cavities moulds & Two shot moulds(with unscrew system)& insert molding with

precision control process and know how to reach the CPK≥1.67.

5. Stability staff, we have many good employees and technicians worked in YF for more than 5 years.

6. Our engineers and project managers are rich experiences and good communication skill in English.

6. Our engineers and project managers are rich experiences and good communication skill in English.

Project Management

You will have dedicated project engineer manager service at YF mold.

The Project Manager is responsible for the project from initial discussions with customer representatives

The Project Manager is responsible for the project from initial discussions with customer representatives

until the project is successfully completed. For the customer this means: One Project – One Contact.

The Project Engineer is responsible for the technical side of each project. He delegates the work to the different departments and is in close contact with the Project Manager.

The Project Engineer is responsible for the technical side of each project. He delegates the work to the different departments and is in close contact with the Project Manager.

The customer gets weekly updates about the project status.

Order Process

RFQ -> Mold flow -> DFM analysis-> Mold design-> Design validation-> Tolerance analysis->

Mold making(full dimension measurement)->Mold trial(free samples, FAI, CPK)->

4hours running before mold delivery.

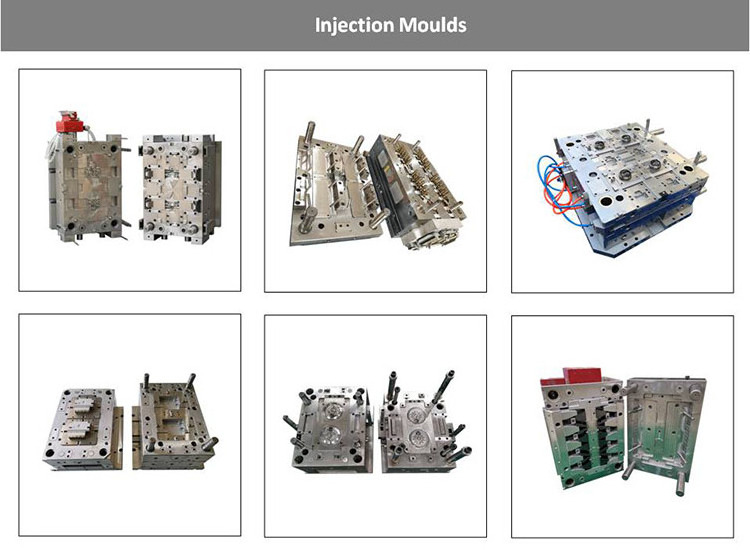

Related Products

Packing&Shipping

We will pack the products according to the shipping way, d

ifferent packaging details for sea, air and land transportation.

FAQ

Q1. Are you a factory or trade company?

We are a factory located in No.5, Guihua Road, Tangxia Yong Community, Songgang Town, Baoan District, Shenzhen. China. Welcome toour factory for inspection.

We are a factory located in No.5, Guihua Road, Tangxia Yong Community, Songgang Town, Baoan District, Shenzhen. China. Welcome toour factory for inspection.

Q2. What kind of production service do you provide?

We provide all services for plastic injection mold making included part analysis, moldflow, mold design, mold manufacturing, plastic injection molding, etc.

We provide all services for plastic injection mold making included part analysis, moldflow, mold design, mold manufacturing, plastic injection molding, etc.

Q3. What type of mold do you make?

We can make different kind of molds like single cavity, multi cavity mold, two shot mold, overmould, insert molding, etc.

We can make different kind of molds like single cavity, multi cavity mold, two shot mold, overmould, insert molding, etc.

Q4. How about the lead time?

Molds : 3-6 weeks

Molding : 1-4 weeks

Molds : 3-6 weeks

Molding : 1-4 weeks

Q5. What documents or data are required for a quote?

It’s better please provide 3D files of the plastic product, resin, quantity of the injection parts, color and surface treatment

customer need.

It’s better please provide 3D files of the plastic product, resin, quantity of the injection parts, color and surface treatment

customer need.

Q6. How long should we take for a quotation?

This is depending by the mold quantities, normally for 1 mold, we are able to quote within 24 hours.

This is depending by the mold quantities, normally for 1 mold, we are able to quote within 24 hours.

Q7. What is payment term in YF mold?

Mould: 40% prepaid, 30% after the first trial sample is confirmed receipt, 30% balance before mold shipping or the mould is

finished.

Molding parts: 30% prepaid, balance T/T before shipment.

Mould: 40% prepaid, 30% after the first trial sample is confirmed receipt, 30% balance before mold shipping or the mould is

finished.

Molding parts: 30% prepaid, balance T/T before shipment.

For more informations, please feel free to contact Yoyo Tang, Thanks!

WhatsApp/WeChat: 13798257041

Company name: Guangdong Yuanfang Technology Industry Co., Ltd.

WhatsApp/WeChat: 13798257041

Company name: Guangdong Yuanfang Technology Industry Co., Ltd.

Email: yoyo“@”

hanking-mould.com

Hot Searches