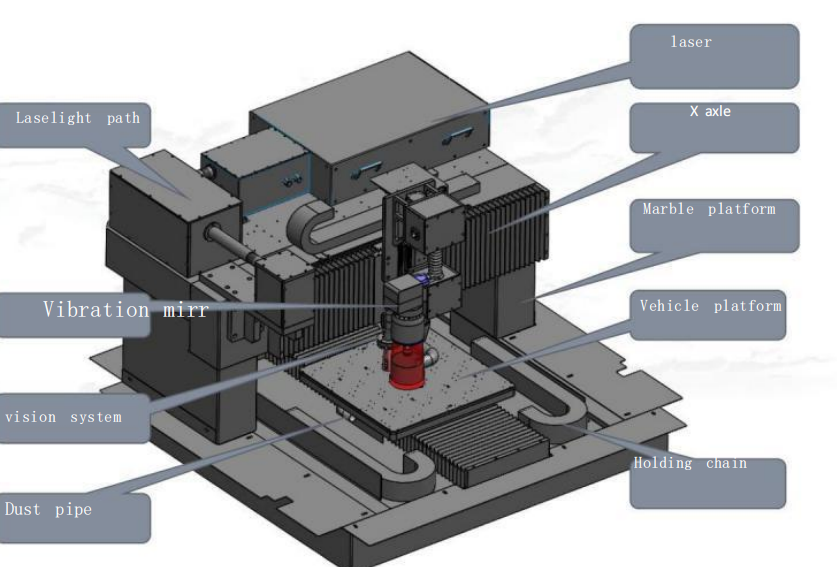

1. Put the product into the vehicle platform and position the product manually;

2. Automatically shift the product to the cutting position;

3. Automatic visual positioning of products;

4. Automatic cut the product;

5. The product of the vehicle shall be removed manually;

8. Repeat what has just happened;

- Product Details

- {{item.text}}

Quick Details

-

Cutting Area:

-

Other

-

Cutting Thickness:

-

< 1 .0 m m (recommended thickness)

-

Place of Origin:

-

Guangdong, China

-

Weight (KG):

-

1800 KG

-

Core Components:

-

laser

-

Galvo Resolution:

-

2μm

-

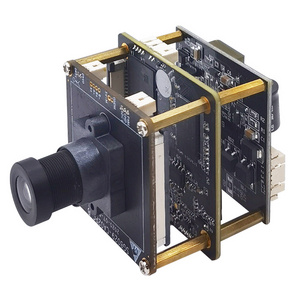

orientation system:

-

CCD + MARK localization

-

Product name:

-

Laser Cutter

-

scanning speed:

-

0-3000mm / s adjustable

-

X / Y movement speed:

-

Max 800mm /s

-

Laser point diameter:

-

0 .17mm

-

Visual positioning accuracy:

-

± 3 μ m

-

pulse length:

-

20ns

-

Pulse frequency:

-

30Hz-300KHz

Quick Details

-

Laser Type:

-

picosecond

-

Cutting Speed:

-

1000-26000mm/min

-

Cooling Mode:

-

WATER COOLING

-

Cutting Area:

-

Other

-

Cutting Thickness:

-

< 1 .0 m m (recommended thickness)

-

Place of Origin:

-

Guangdong, China

-

Weight (KG):

-

1800 KG

-

Core Components:

-

laser

-

Galvo Resolution:

-

2μm

-

orientation system:

-

CCD + MARK localization

-

Product name:

-

Laser Cutter

-

scanning speed:

-

0-3000mm / s adjustable

-

X / Y movement speed:

-

Max 800mm /s

-

Laser point diameter:

-

0 .17mm

-

Visual positioning accuracy:

-

± 3 μ m

-

pulse length:

-

20ns

-

Pulse frequency:

-

30Hz-300KHz

Laser Precision Cutting Machine

The equipment mainly consists of marble movement gantry module, 80 square meters. Through the frame sheet metal, vacuum adsorption platform, CCD visual positioning machine Structure, product placement vehicle, laser flight light path and fine close composition of the cutting software control system.

CONTACT:

Queena's Whatsapp/wechat:(86)14707395870

Product Description

Equipment action process description:

Equipment industry application

Precision cutting machine developed for 3C electronics industry. Using the original imported laser, reasonable and excellent.

The chemical light road focus structure is combined with the linear motor motion platform, and it is equipped with the ideal electronic control system and the professional visual counterpoint cutting control software.

Industry applications are embodied in the following aspects:

1.PCB thin hard cutting (including assembled circuit board);

2. Cover the film window, just scratch the circuit board uncovers the cover, shape cutting;

3. Fine cutting, depth digging, drilling of the circuit board of FPC, FR

4, camera module, flexible circuit board, covering film, Micro SD (TF)card, etc.

Advantages:

1. Special vehicles with laser processing, even if the components are very close from the cutting path, there is no stress influence; 2. According to different thermal impact requirements, select suitable laser types, and cooperate with suitable laser processing parameters to minimize the thermal impact; 3. Adopt marble precision platform for stable bearing capacity and corrosion resistance; 4. Use linear motor with optical ruler full closed-loop drive processing platform, which is easy to maintain, long life and high precision; 5. Imported high-power laser, fast processing speed, high stability and long service life; 6. Imported vibrator scanning head, long-term use of temperature drift, stable accuracy; 7. Adopt high negative pressure air machine adsorption products to ensure positioning stability; 8. Built-in power supply regulator, safety protection equipment and electrical appliances, stable and reliable; 9. Configuration of self-contained, motion-opposite CCD and visual lens, which can accurately identify various Mark points; 10. Professional cutting software, easy to learn and easy to use; simple operation; 11. Automation: open ports are reserved for all kinds of automation needs;

1. Special vehicles with laser processing, even if the components are very close from the cutting path, there is no stress influence; 2. According to different thermal impact requirements, select suitable laser types, and cooperate with suitable laser processing parameters to minimize the thermal impact; 3. Adopt marble precision platform for stable bearing capacity and corrosion resistance; 4. Use linear motor with optical ruler full closed-loop drive processing platform, which is easy to maintain, long life and high precision; 5. Imported high-power laser, fast processing speed, high stability and long service life; 6. Imported vibrator scanning head, long-term use of temperature drift, stable accuracy; 7. Adopt high negative pressure air machine adsorption products to ensure positioning stability; 8. Built-in power supply regulator, safety protection equipment and electrical appliances, stable and reliable; 9. Configuration of self-contained, motion-opposite CCD and visual lens, which can accurately identify various Mark points; 10. Professional cutting software, easy to learn and easy to use; simple operation; 11. Automation: open ports are reserved for all kinds of automation needs;

Specification

|

cooling-down method:

|

Water-cooling

|

|

Galvo Resolution:

|

2μm

|

|

Focus:

|

telecentric mirror

|

|

Focus on the spot:

|

≤ Ф 30um

|

|

scanning speed:

|

0-3000mm/s adjustable

|

|

ambient temperature:

|

22℃±2 ℃(71 .6 ℉±2 ℉)

|

|

CCD :

|

1 / 2 " Gray-scale CCD

|

|

Visual positioning accuracy:

|

± 3 μ m

|

Product packaging

*After placing an orderthe delivery lead time is usually within 10 working days

Our Services

After-sales services

*Engineers available to service machinery overseas;

*Training how to install and use the machine;

*Free parts;

Pre-sales services

*Inquiring and consulting support;

*Sample testing support;

*Visiting our factory;

*Inquiring and consulting support;

*Sample testing support;

*Visiting our factory;

After-sales services

*Engineers available to service machinery overseas;

*Training how to install and use the machine;

*Free parts;

Payment:

Alibaba Assurance Order payment link; TT; LC; Western Union; Paypal

Alibaba Assurance Order payment link; TT; LC; Western Union; Paypal

Packing :

Depends on different situation (weight, volume, country...), the shipping method could be different and its negotiable.

Depends on different situation (weight, volume, country...), the shipping method could be different and its negotiable.

Hot Searches