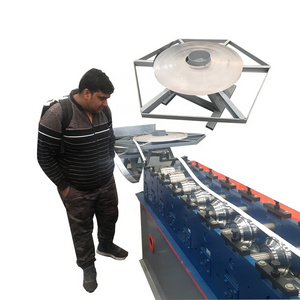

1 3TONS HYDRAULIC

DECOILER

1

2

FEEDING PLATFORM

1

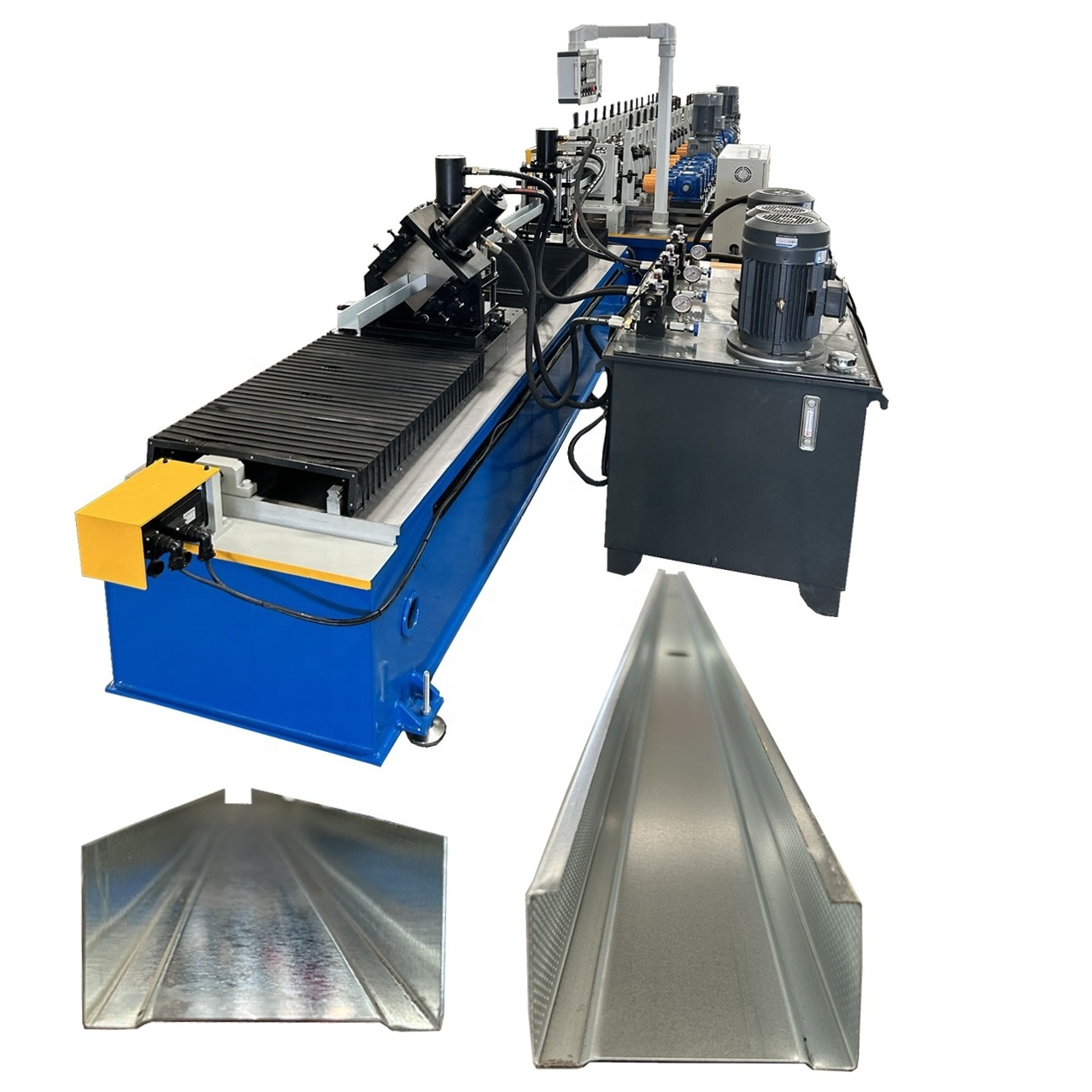

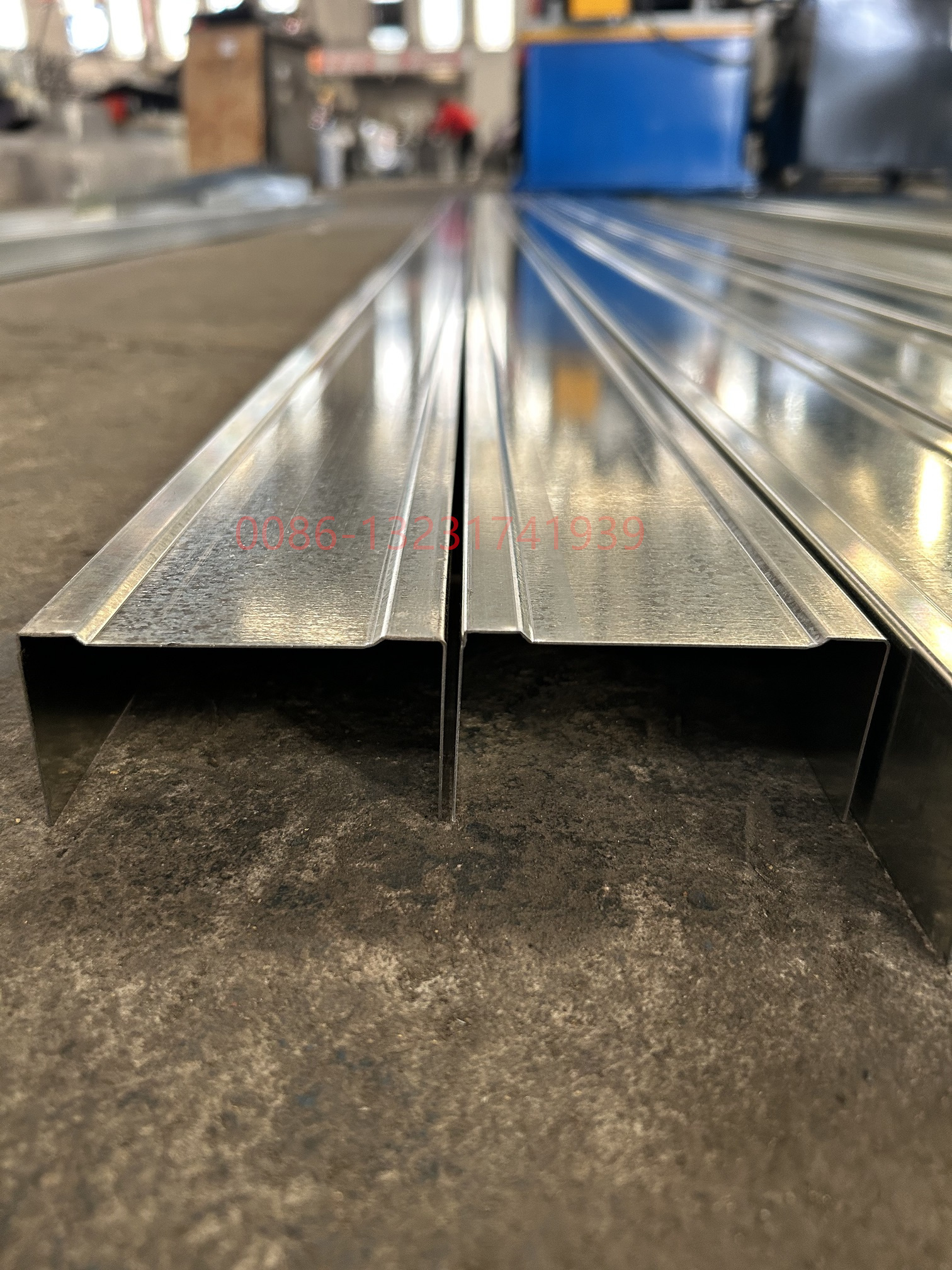

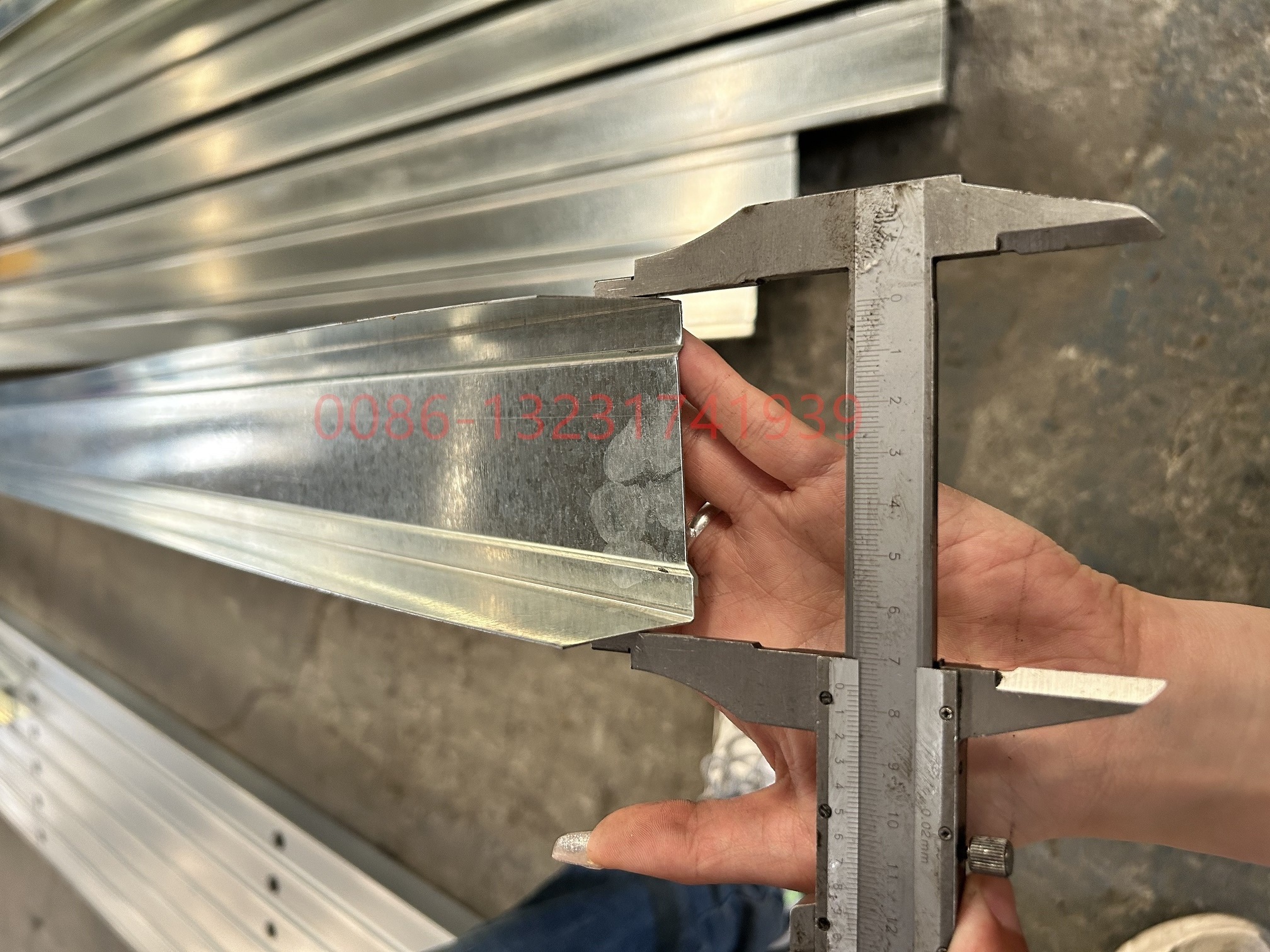

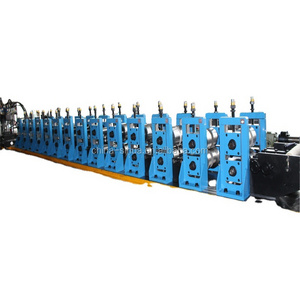

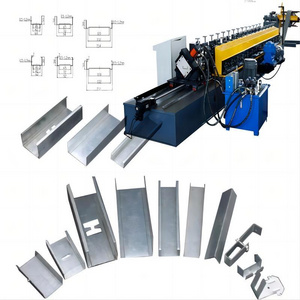

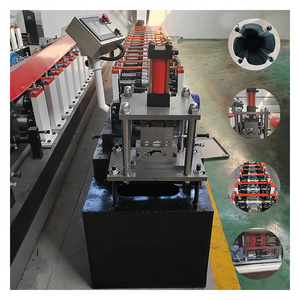

3 FORMING PART 1

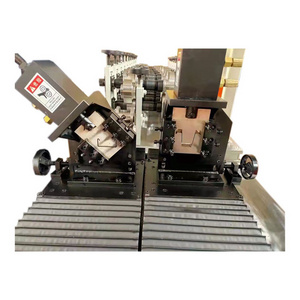

4 NONE STOP PUNCHING PART 2

5 NONE-STOP CUTTING PART 1

6 ELECTRIC CONTROL CABINET 1

7 HYDRAULIC PUMP STATION 1

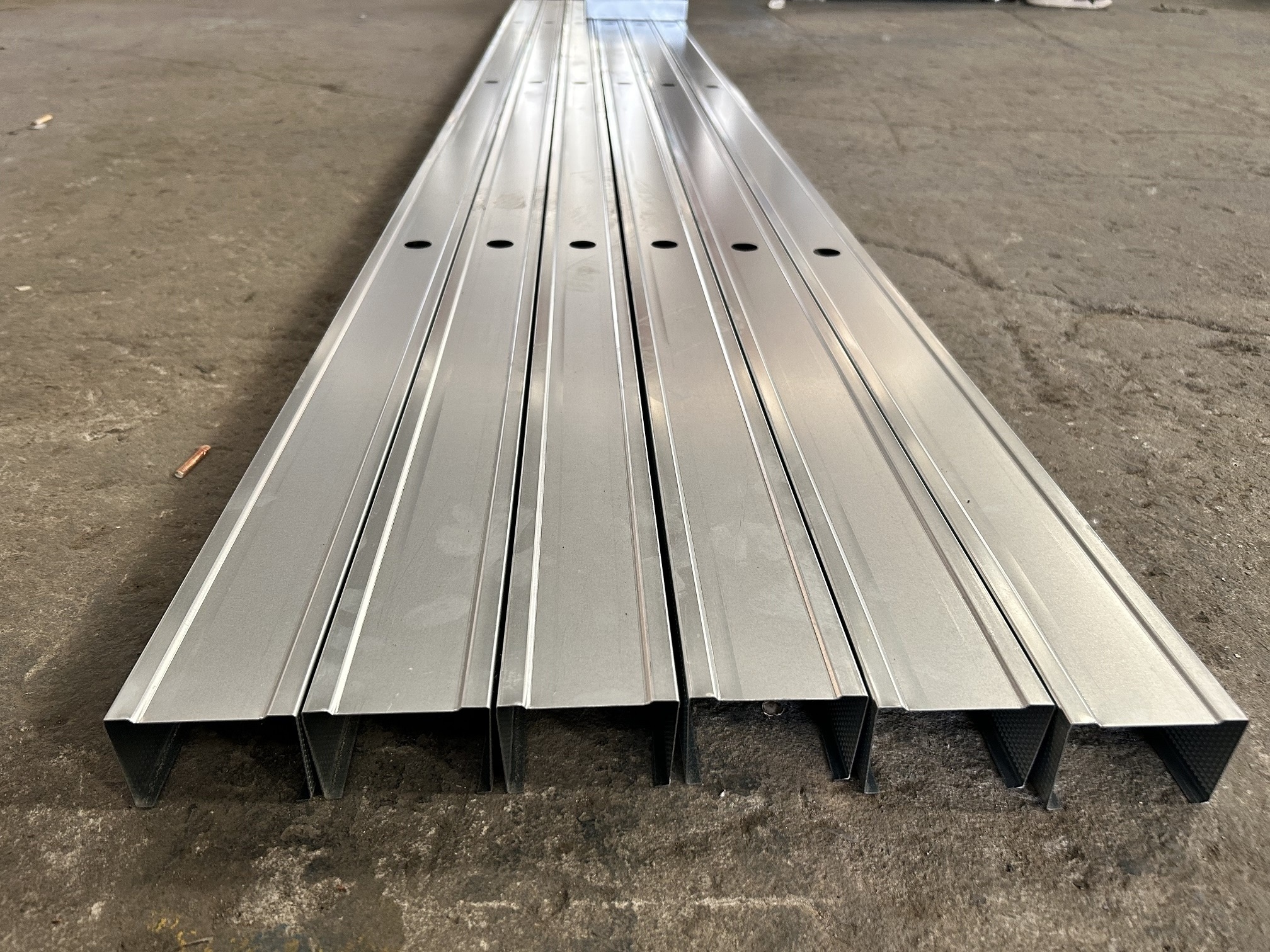

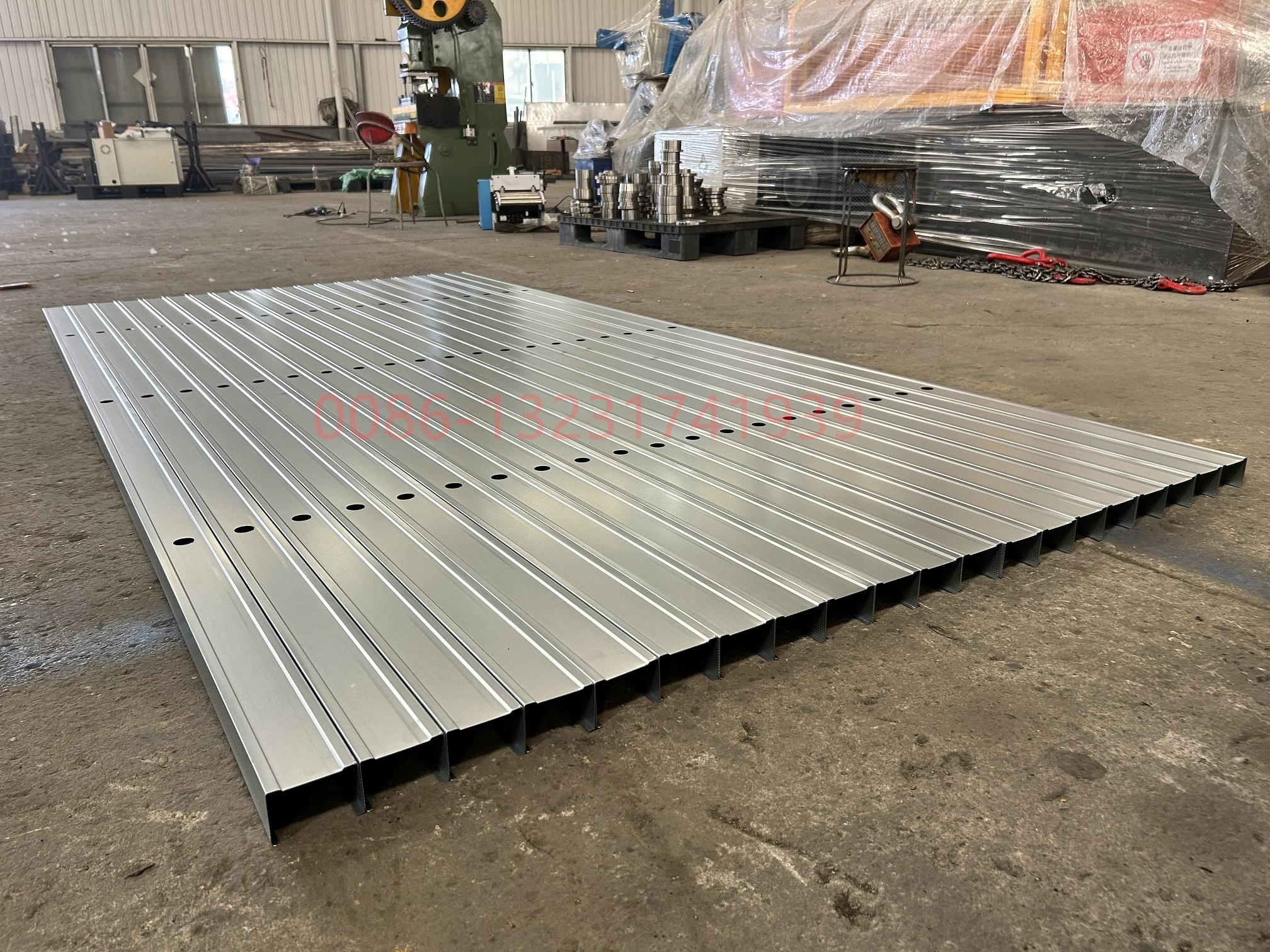

8 RUN OUT TABLE 1

9 ACCESSORIES 1

10 SERVO NON-STOP PUNCHING MOTOR 1