- Product Details

- {{item.text}}

Quick Details

-

Brand Name:

-

Robotphoenix

-

Weight:

-

1.5 KG

-

Product name:

-

bottle unscrambler machine,pet bottle with delta robot design

-

Keyword:

-

robotic bottle unscrambler

-

Speed:

-

60--200 bottles/min

-

bottle type:

-

consumer goods bottle

-

total power:

-

1.5 Kw

-

electric source:

-

380/220V, 50/60 Hz

-

customization:

-

available

Quick Details

-

Voltage:

-

380/220V, 50/60 Hz

-

Power:

-

1.5Kw

-

Place of Origin:

-

Shandong, China

-

Brand Name:

-

Robotphoenix

-

Weight:

-

1.5 KG

-

Product name:

-

bottle unscrambler machine,pet bottle with delta robot design

-

Keyword:

-

robotic bottle unscrambler

-

Speed:

-

60--200 bottles/min

-

bottle type:

-

consumer goods bottle

-

total power:

-

1.5 Kw

-

electric source:

-

380/220V, 50/60 Hz

-

customization:

-

available

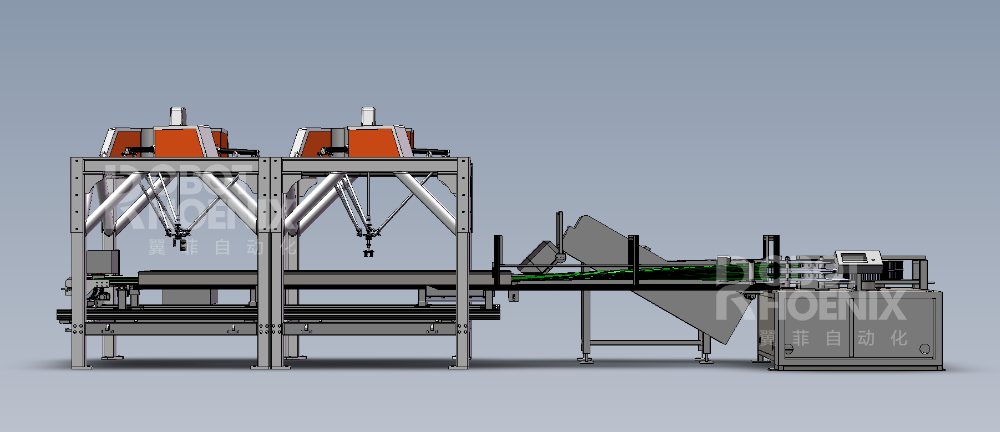

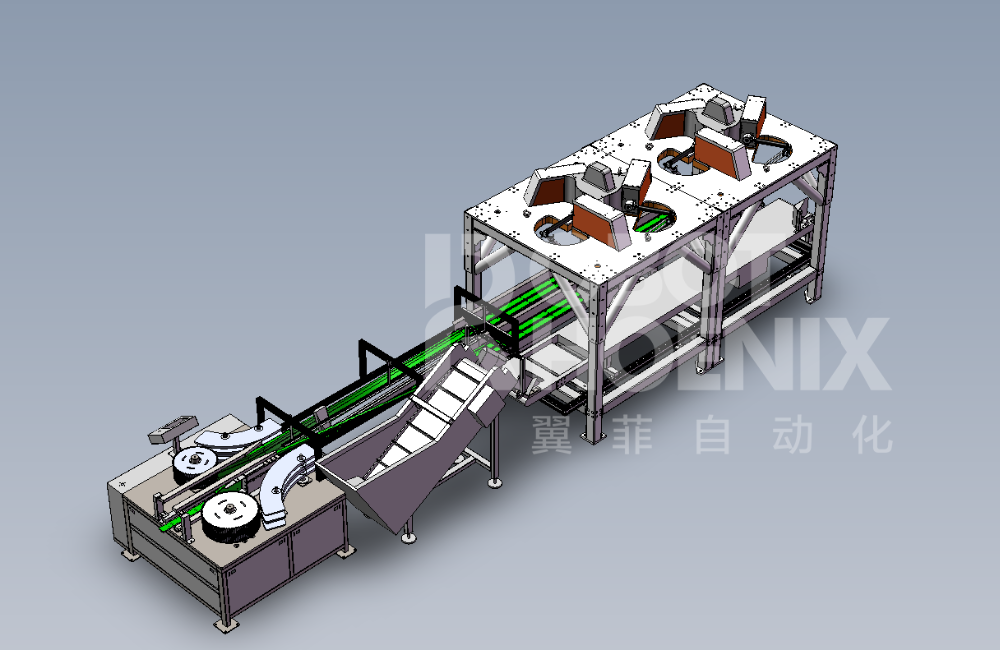

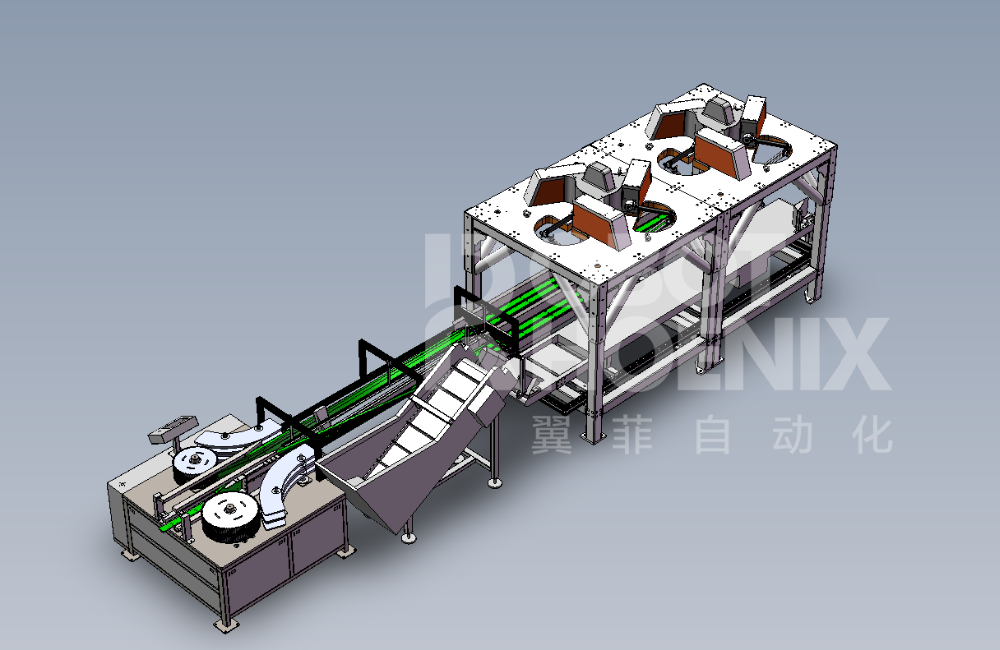

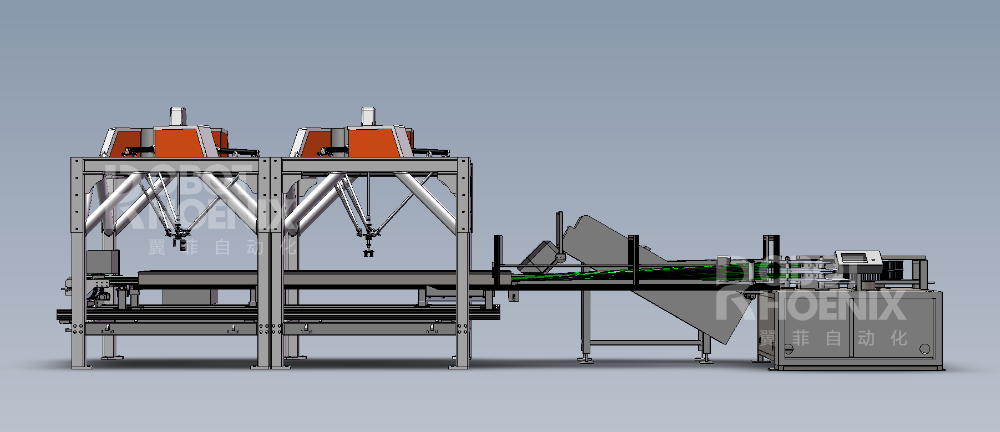

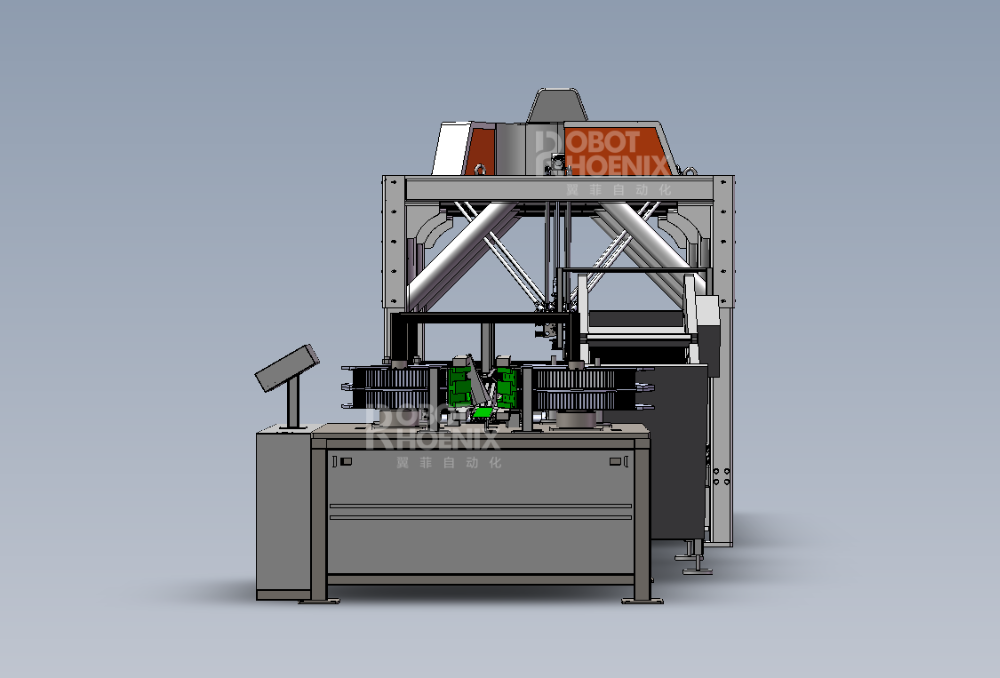

New 180ppm plastic chubby gorilla bottle robotic bottle unscrambler with delta robot design

The system, making use of

2D vision technology

, could inspect the front-back sides, types, angles, etc. Information of the unsorted incoming bottles. The machine, based on the information feedback signaled by the vision system, could select proper gripping position, rotate 90 degree angle, and place the bottle onto the conveyor according to the same principle. The maximum speed of the system could reach 150-180 pcs/min, 2

delta robots

work collaboratively to reduce manual workforce greatly. The system could widely used in daily chemical industry.

|

Number of robots

|

1,2,3 optional

|

|

Robot type

|

Delta robot

|

|

Speed rate

|

100 - 180 pieces per minute

|

|

Interface

|

Panel PC 18,53''

|

|

Bottle Material

|

Plastic

|

|

Bottle Dimension

|

from 20 ml up to 5 L

|

|

Bottle feeding system

|

in bulk

|

|

Feeding through

|

hopper feeder

|

|

Hopper Feeder Volume

|

from 300 up to 1000 litres

|

1.Little damage to the bottle bodies

2.Convenient operation for changeover in a short time, less in 2 hours.

3.Tailor-made for shampoo, sauce and other daily consumer goods.

4.Humanized HMI design, operation easy to learn.

5.Save up to 5 workers.

6.Capable of running 24/7.

7.Customization accepted

.

Our Package Advantage:

1.Our wooden case is after fumigation treatment.Needn't timber inspection,saving shipping time.

2.All the spare parts of the machine were covered by some soft materials,mainly using pearl wool.

Avoiding all damages that could happen in the delivery process.Then we'll covered plastic wrap out it tightly,make sure intact of the covered soft materials,also avoiding Waterproof and rust proof.

3.The outmost is wooden case with fixed formwork.

4.The bottom of the wooden case has firm iron jack,convenient to Handling and transport.

Robot Phoenix LLC, founded in 2012, is a robotics company headquartered in Jinan, China, with branches located in Shenzhen, Shanghai. As the market leader for industrial automation in China, our products and services include high-performance industrial robot development, turn-key industrial automation systems, equipment manufacturing, robotics and computer vision system development and all related services. Our flagship product-BAT series robots-have been widely used in food, pharmaceutical, photovoltaic, electronics, daily chemical and logistics industries, to reduce cost in sorting, handling, packaging, coating, palleting, etc.. The standard machine--wet wipe lid application machine, after years experience in this field, takes the largest domestic market share in the market up to today. Robotphoenix's experienced research and development team are here to provide our customers with top-quality and affordable industrial automation solutions and services.

Q: I knew nothing about this machine, what kind of machine I should choose?

A: Just tell us what you want to do with the automation production line, we will give you perfect solutions and suggestions and take care of all your needs.

Q: What is the lead time?

A: 30-60 working days after receiving advance payment.

Q: What about the payment?

A: 30% down payment of total value along with the order by T/T

70% balance payable before shipment by T/T or L/C

Q: What about the shipment?

A: By sea/air from the QINGDAO Port (Shandong China) or customer designated ports in China.

Q: When I got this machine, but I don't know how to use it. What should I do?

A: We are responsible for the installation and training of the new machine, at customer site. At the same time, video and English manual will be delivered together with the machine.

Q: What's your Warranty date?

A: 12 months from the date of shipment. Also professional engineer is available in case of any machine break down.

Q: If some problems happen to this machine during warranty period, what should I do?

A: We will supply free parts during machine warranty period if machine have some problems. While we also supply free life long after-sales service, 24/7. So any doubts, just let us know, our professional engineers will respond to your question with no delay.

Q: How can I make sure the machine is ok before delivery?

A: We will film the machine operation video for you to check, and adjust the machine till you are satisfied.