- Product Details

- {{item.text}}

Quick Details

-

Power:

-

180kw

-

Dimension(L*W*H):

-

4140*2280*2425 mm

-

Weight:

-

10.3 t

-

After-sales Service Provided:

-

No after-sales service, Free spare parts, Field installation, commissioning and training

-

Application:

-

Quarry

-

Product name:

-

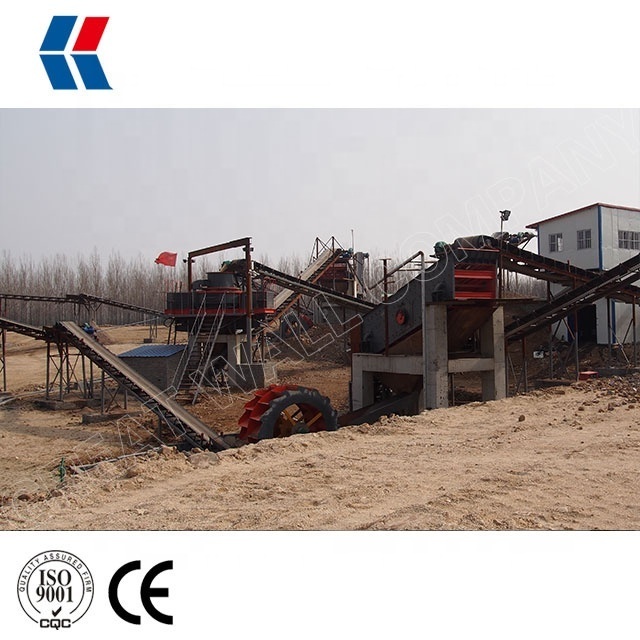

Silica Sand Production Line

-

Color:

-

Small VSI Sand Making Equipment Quartz Sand Processing Plant

-

The Machines classification:

-

Silica Sand Production Line

-

Spare Parts Supply:

-

Life Long Provide

-

Processed Materials:

-

Limestone, granite, marble

-

Max Feed Size:

-

35mm

-

Output Size:

-

<5mm

-

Model:

-

VSI-8518

-

Certification:

-

CE&ISO9001:2015

Quick Details

-

Place of Origin:

-

Henan, China

-

Brand Name:

-

Great Wall VSI Sand Making

-

Voltage:

-

380v, 50hz, 3phase

-

Power:

-

180kw

-

Dimension(L*W*H):

-

4140*2280*2425 mm

-

Weight:

-

10.3 t

-

After-sales Service Provided:

-

No after-sales service, Free spare parts, Field installation, commissioning and training

-

Application:

-

Quarry

-

Product name:

-

Silica Sand Production Line

-

Color:

-

Small VSI Sand Making Equipment Quartz Sand Processing Plant

-

The Machines classification:

-

Silica Sand Production Line

-

Spare Parts Supply:

-

Life Long Provide

-

Processed Materials:

-

Limestone, granite, marble

-

Max Feed Size:

-

35mm

-

Output Size:

-

<5mm

-

Model:

-

VSI-8518

-

Certification:

-

CE&ISO9001:2015

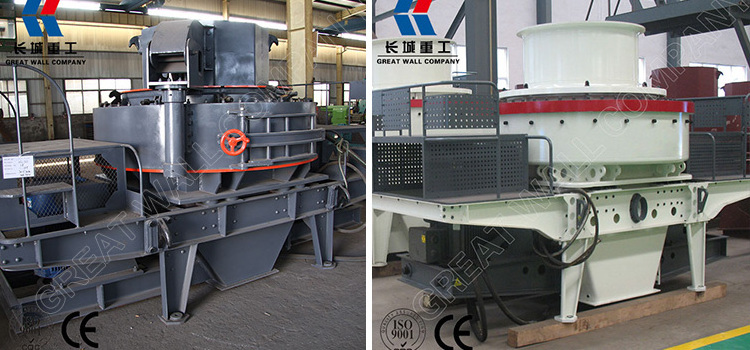

Price VSI Sand Making Equipment Quartz Sand Processing Plant

"Great Wall Make Great Machine"

Price VSI Sand Making Equipment Quartz Sand Processing Plant

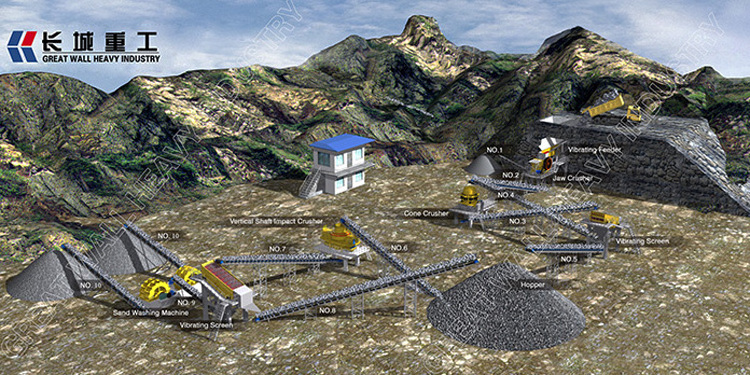

| Usage and Application Price Small VSI Sand Making Equipment Quartz Sand Processing Plant |

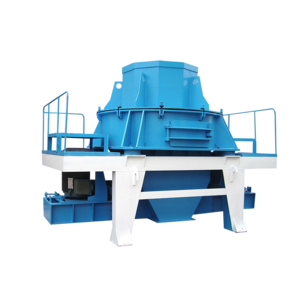

The Vertical Shaft Impact Crusher is an advanced and high-efficiency equipment. It is the latest researched results basing on Germany technology. The machine is professional in producing qualified sand and stone for highway, high-speed railway, high building, city project, hydropower dam constructions, and concrete mixing plant. It is the best choice for sand making and stone reshaping industry.

| Working Principle Price Small VSI Sand Making Equipment Quartz Sand Processing Plant |

Entire Center Feeding: Materials fall into the hopper of VSI, then get into the high speed rotating wheelie through center feeding hole. Materials are speed up rapidly in the wheelie, the speed can be dozens of times of gravity acceleration, then shoot out at high speed and hit against the materials falling free after being rebounded, then they are all impacted to the liner layer of materials to strike against each other, or to the counterattack board to be bounded oblique upward to the top of the eddy current cavity, then change their heading, deflect and move downward, then strike against the materials shot out from the impeller passage, which forms continuous material flow. So the materials are hit, rubbed and grinded for two or more times in the eddy current crushing cavity. The crushed materials are discharged from the lower outlet.

| Features Price Small VSI Sand Making Equipment Quartz Sand Processing Plant |

1.Oil supplied by two oil pumps, stops automatically if there is no oil; cooled by water, heating the motor firstly if start the machine in winter.

2.Hydraulic lifting when changing or checking the spare parts which makes it easy and convenient in maintenance.

3.Famous brand SKF or TIMKEN of the bearing makes the machine work well and few problems.

4.Vibrating alarm device; if the crusher works abnormally, alarm will sound to make the machine stop working so as to protect the crusher.

5.Special feeding structure; rock on rock, and rock on iron in the crusher making the stone to be crushed and reshaped.

6.Unique dustproof seal system, protects the lubrications parts from the dust outside.

7.Perfect design on material bumping angle reduces the friction between raw material and quick-wear parts, prolongs the service time of quick-wear parts and cuts the cost.

| Model | VSI-7611 | VSI-8518 | VSI-9526 | VSI-1140 | ||

|

Capacity

(t/h) |

Center and Sides Feeding | 120-180 | 200-260 | 300-380 | 450-520 | |

| Center Feeding | 60-90 | 100-130 | 150-190 | 225-260 | ||

| Max. Feeding Size (mm) | Soft Material | 35 | 40 | 45 | 50 | |

| Hard Material | 30 | 35 | 40 | 45 | ||

| Rotation Speed(rpm) | 1700-1890 | 1520-1690 | 1360-1510 | 1180-1310 | ||

| Double Motor Power (kW) | 110 | 180 | 264 | 400 | ||

|

Overall Dimension

L×W×H (mm) |

3700×2150×2100 | 4140×2280×2425 | 4560×2447×2778 | 5000×2700×3300 | ||

| Weight (t) | 7.8 | 10.3 | 16 | 25.6 | ||

| Vibration Sensor | Inspection scope: 0.1-20mm/s continual adjustment | |||||

| Hydraulic oil pump | Motor Power of Double Oil Pump(kw) | 2×0.31 | ||||

|

Overall Dimension

L×W×H (mm) |

820×520×1270 | |||||

| Power of Oil Tank Heater(kW) | 2 | |||||

| Zhengzhou Great Wall Heavy Industry Machinery Co., Ltd |

|

Tel: 0086-371-63769782

Fax:

0086-371-63769781

|