- Product Details

- {{item.text}}

Quick Details

-

Voltage:

-

380V

-

Weight (T):

-

0.2 T

-

Power (kW):

-

Customized

-

Aluminum Melting:

-

Cost-effective

Quick Details

-

Place of Origin:

-

Liaoning, China

-

Marketing Type:

-

Hot Product 2023

-

Brand Name:

-

Mingcheng

-

Voltage:

-

380V

-

Weight (T):

-

0.2 T

-

Power (kW):

-

Customized

-

Aluminum Melting:

-

Cost-effective

Contacts: Mark Liu

Tel: +86-411-82766928

Fax: +86-411-39015062

Email: Liu@weldcnc.com

Mob/Whatsapp: +86 133 9411 0095

Products Description

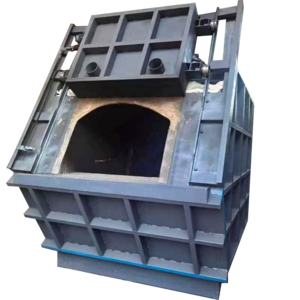

Aluminum Melting Furnace/Aluminum Alloy Rapidly Melting Furnace

Aluminum Melting Furnace

Features

1. With renewable biomass pellet fuel as an energy source, the use cost is low. 2. Semi-gasification combined combustion with tangential swirl air distribution design, low-temperature stage combustion, and burnout rate of more than 98%. 3. Micro-positive pressure operation, no tempering, and defining phenomenon. 4. Low emission of soot, sulfur, and nitrogen. 5. Adopt air-cooled protection, simple refitting, automatic feeding, and simple operation.

Aluminum Alloy Rapidly Melting Furnace

1. No crucible design, more energy saving, and environmental protection; 2. High-alumina anti-penetration refractory material is used, which does not occupy slag or hang slag, and the service life of the furnace lining is about five years; 3. Using microporous nano-insulation board and aluminum fiber insulation material, the average temperature rise of the furnace wall is low; 4. The control system adopts PLC mode, which makes the operation of the equipment safer and more reliable. We can adopt different man-machine interfaces according to user needs; 5. Using high wind pressure direct flame burner, the comprehensive burning loss of materials is less than 1.5%; 6. Dissolving capacity: 250kg/h-3000kg/h 7. Fuels with different properties and calorific values can be selected, such as light oil, liquefied petroleum gas, natural gas, city gas, etc.

Aluminum Melting Furnace

Brand: MC

Original: China

Brand: MC

Original: China

Common aluminum melting furnace types are mostly rectangular or garden-shaped two structural forms, reasonable aluminum melting furnace structure design can significantly improve the furnace heat transfer effect, improve melting capacity, and reduce energy consumption.

It can achieve the effect of reducing consumption, reducing burning, improving product quality, reducing labor intensity, improving working conditions, and improving production efficiency, suitable for intermittent operations, with more smelting of gold and return materials.

Aluminum Alloy Rapidly Melting Furnace

Brand: MC

Original: China

The aluminum alloy rapidly melting furnace is a new type of high-efficiency and energy-saving aluminum melting furnace developed according to the aluminum smelting process. It is mainly used for smelting and heat preservation of aluminum ingots, which can well meet the aluminum smelting process. The furnace is designed without a crucible for longer service life and less material damage.

Natural Gas Regenerative Burner for Aluminum Melting Furnace

The regenerative burner can heat the air at normal temperature in a very short time. It has the advantage of saving energy in alternate working states of heat storage and heat release.

The regenerative burner heats the air at normal temperature in a very short time. After the heated high-temperature air enters the furnace, it entrains the flue gas in the surrounding furnace to form a thin and oxygen-poor high-temperature airflow with low oxygen content, and at the same time, it flows into the thin air. The fuel is injected near the high-temperature air, and the fuel is burned in an oxygen-depleted state.

Product Paramenters

|

SPECIFICATIONS FOR ALUMINUM ALLOY RAPIDLY MELTING FURNACE

|

|

|

|

|

|

|

|

|||||||

|

Model

|

Melting Quantity (kg/h)

|

Burner Capacity

|

|

Bath Capacity (kg)

|

Outline Dimension

|

Outline Dimension

|

|

|||||||

|

|

|

Melting Burners

(kcal/ h)

|

Heat-insulating Burner

(kcal/ h) |

|

Overall Length

(mm)

|

Overall Bandwidth

(mm) |

Total Height

(mm) |

|||||||

|

FRM-300

|

300

|

20×10

4

|

20×10

4

|

1000

|

5300

|

2900

|

5500

|

|||||||

|

FRM-500

|

500

|

20×10

4

|

20×10

4

|

1500

|

5600

|

3500

|

6500

|

|||||||

|

FRM-750

|

750

|

30×10

4

|

30×10

4

|

2000

|

6000

|

3850

|

6700

|

|||||||

|

FRM-1000

|

1000

|

30×10

4

×2

|

40×10

4

|

2400

|

6100

|

4300

|

7150

|

|||||||

|

FRM-1500

|

1500

|

30×10

4

×2

|

60×10

4

|

3000

|

6350

|

4400

|

7200

|

|||||||

|

FRM-2000

|

2000

|

40×10

4

×3

|

60×10

4

|

5000

|

8000

|

4600

|

7500

|

|||||||

Recommend Products

Hot Searches