- Product Details

- {{item.text}}

Quick Details

-

Machinery Capacity:

-

pressure cooker

-

Machinery Function:

-

electric pressure cooker

-

Usage:

-

Pneumatic Pressure Cooking Kettle with basket

-

Materials::

-

SS304,SS316L

-

Application:

-

pressure Cooking Kettle with basket

-

Capacity:

-

100-5000L(as your requirement)

-

Heating method:

-

steam, electric heating and heat guiding oil

-

Heating and cooloing:

-

Full jacket, semi-tube, coil structure etc.

-

Mixer:

-

with or with out

-

Advantage:

-

anti-acid, anti-high-temperature, anti-abrasion and anti-corrosion

-

Machine type:

-

food cooking kettle machine

-

Product Type:

-

pressure cooker stainless steel kettle

Quick Details

-

Weight (KG):

-

1000

-

Place of Origin:

-

Zhejiang, China

-

Brand Name:

-

L&B

-

Machinery Capacity:

-

pressure cooker

-

Machinery Function:

-

electric pressure cooker

-

Usage:

-

Pneumatic Pressure Cooking Kettle with basket

-

Materials::

-

SS304,SS316L

-

Application:

-

pressure Cooking Kettle with basket

-

Capacity:

-

100-5000L(as your requirement)

-

Heating method:

-

steam, electric heating and heat guiding oil

-

Heating and cooloing:

-

Full jacket, semi-tube, coil structure etc.

-

Mixer:

-

with or with out

-

Advantage:

-

anti-acid, anti-high-temperature, anti-abrasion and anti-corrosion

-

Machine type:

-

food cooking kettle machine

-

Product Type:

-

pressure cooker stainless steel kettle

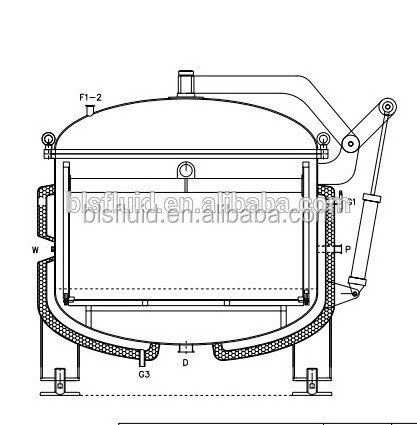

Automatic Chicken Mutton Vacuum Marinating Machine/steel pneumatic jacketed steel electrical Meat Marinator pressure cooker

Cooking boiler, also called high pressure cooking tank, sealed cooking tank.

Cooking pot is widely used in the processing of candy, pharmacy, dairy, alcohol, cakes, candied fruit, beverage, canned food, lo mei and so on. It can also be used for tea leaching and other pre-cooking, heating and mixing. With a large heating area, high thermal efficiency, uniform heating, liquid boiling short time, easy to control heating temperature and so on.

Reference parameters:

1, the volume: 100-10000L.

2, the structure: tilting, vertical structure, according to the process needs to be used with stirring without mixing.

3, pot body material: both inside and outside the whole stainless steel SS304 or SS36L.

4, the heating method: electric heating or steam heating.

5, with mixing device pot body: the top center of the mixing, reducer output shaft and stirrup shaft with Looper connection, easy disassembly and cleaning.

6, stirring speed: 36r / min (according to customer requirements to select a certain speed); stirring paddle form: ordinary mixing (anchor) and scraping bottom stirring.

7, the foot form: ① vertical pot: three pyramidal form, tube type; ② tilting pot: groove bracket.

8, equipment configuration: basket filter, thermometer, pressure gauge, steam inlet, outlet and so on.

9, tilting cooking pot the maximum tilting 90 °, tilting the way for manual or electric.

|

Volume (L)

|

Dimension D*h (mm*mm)

|

Height (mm)

|

In/Outlet diameter (mm)

|

Heat preservation layer

|

|

1000

|

1060*1220

|

2550

|

51

|

60

|

|

1500

|

1160*1500

|

2850

|

51

|

60

|

|

2000

|

1340*1500

|

2900

|

51

|

60

|

|

3000

|

1410*2000

|

3400

|

51

|

60

|

|

4000

|

1620*2000

|

3450

|

51

|

60

|

|

5000

|

1810*2000

|

3500

|

51

|

60

|

|

6000

|

1930*2000

|

3550

|

51

|

60

|

|

7000

|

1930*2440

|

4000

|

51

|

60

|

|

8000

|

2060*2440

|

4000

|

51

|

60

|

|

9000

|

2180*2440

|

4050

|

51

|

60

|

|

10000

|

2300*2440

|

4050

|

51

|

60

|

|

12000

|

2270*3000

|

4600

|

51

|

60

|

|

15000

|

2530*3000

|

4700

|

51

|

60

|

|

20000

|

2640*3660

|

5400

|

51

|

60

|

Quality stainless steel

1.SS304 and SS316 sanitary stainless steel

2. sanitary polishing, 3A standard

3. adopt rapid installation type connection form, with convenient assembly, disassembly and cleaning.

Surface treatment

1. Flange shell cover and Inner surface: polished

2. Tank body Outer surface: Sandblast

Pneumatic open cover

Be provided with pneumatic cylinder, easy to open cover

2. Manual or electric control cover open and close

SUS control panel

thermometer

show the inside tank feeding material temperature

Optional parts:

Stainless steel basket filter

Electric heating:

Drain valve

Ball valve, can get rid of extra water inside interlining

Bolted Flange shell cover

Zhejiang L&B Fluid Equipment co., Ltd

a modern enterprise which combine the ability of design, development, manufacturing, engineering, installation, technical services, has special technology to design and exploit by CAD software and computer and is a outstanding leader among valve fields.

We have advanced CNC lathes imported from Japan.We can manufacture the valves and fitting according to ISO, DIN, IDF, SMS, 3A, while we can produce the products per as the requirement from the clients(non-standard).

We are specialized in producing different kinds of valves, pipe fitting, tubes, manhole covers, pumps, tanks etc for many years. We can design the products according to your special request. OEM is welcome too.

Q1. What is your terms of packing?

A: Generally, we pack our goods in plywood case or carton package for small parts.

If you have legally registered patent, we can pack the goods in your branded boxes after getting your authorization letters.

Q2. What is your terms of payment?

A: T/T in advance, 30% as deposit, and finish 70% balance payment before delivery.

We'll show you the photos of the products and packages before you pay the balance.

Q3. What is your terms of delivery?

A: EXW, FOB, CIF, DDU.

Q4. How about your delivery time?

A: Generally, it will take 3 to 4 weeks after receiving your advance payment. The specific delivery time depends

on the items and the quantity of your order.

Q5. Can you produce according to the samples?

A: Yes, we can produce by your samples or technical drawings.

Q6.Do you test all your goods before delivery?

A: Yes, we have 100% test before delivery

Q7: How do you make our business long-term and good relationship?

A:1. We keep good quality and competitive price to ensure our customers benefit ;

2. We respect every customer as our friend and we sincerely do business and make friends with them, no matter where they come from.

|

Please contact our After-sales service department in time within 30days after you received the cargo.

|

|

|

|

Tel: 86-577-86821328 Time: 9:00 a.m.- 6:00 p.m. (Beijing time)

|

|

|

|

Process

|

Please provide the copy of Sales Contract and describe the problems appeared.

|

|

|

Problems confrimation:

|

|

|

|

Slight problem:

|

Please send the proof to our After-Sales Department, we will reply within two days.

|

|

|

Serious problem:

|

|

|

|

a

|

We will dispatch our Quality and Problems Appraisers to make a confirmation.

|

|

|

b

|

Have a negotiation of the compensation and sign agreements

|

|

|

c

|

Our After-Sales Department will perform the duties as the agreements

|

|