- Product Details

- {{item.text}}

Quick Details

-

Brand Name:

-

Locking Wheel Nuts

-

Model Number:

-

Locking Wheel Nuts

Quick Details

-

Size:

-

Various

-

Car Make:

-

Universal

-

Place of Origin:

-

Taiwan, China

-

Brand Name:

-

Locking Wheel Nuts

-

Model Number:

-

Locking Wheel Nuts

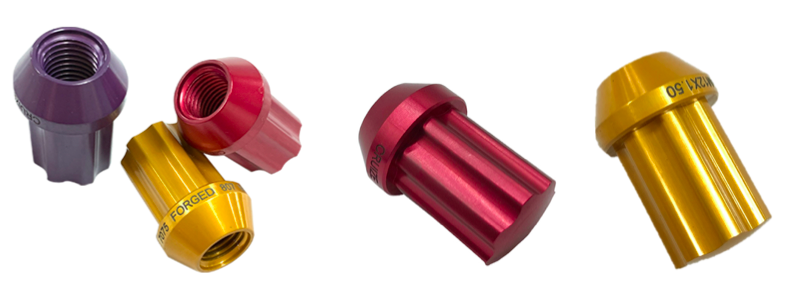

Automotive Locking Wheel Nuts of Precision Parts

|

19HEX close-end

Shape: 60-degree Taper Material:7075 Forged Aluminum T6 |

|||

| Item NO. |

Total Length |

Pitch | Color |

|

M12 9HEX 28mm |

1.25 |

Chrome |

|

| A05602904 |

M12 19HEX 28mm |

1.5 | Chrome |

|

M12 19HEX 35mm |

1.25 |

Chrome, Red |

|

|

M12 19HEX 35mm |

1.5 |

Chrome, Purple |

|

|

M12 19HEX 40mm |

1.25 |

Chrome, Red | |

| A05602701 | M12 19HEX 40mm |

1.5 |

Chrome, Yellow |

|

M14 19HEX 35mm |

1.5 |

Chrome, Blue, Red | |

| M14 19HEX 40mm | 1.5 | Chrome | |

|

LOCK7

Shape: 60-degree Taper Material:7075 Forged Aluminum T6 |

|||

| Item NO. | Total Length | Pitch | Color |

|

M12 LOCK7 28mm |

1.25 |

Chrome | |

| M12 LOCK7 35mm | 1.5 | Red, Yellow, Purple | |

| M12 LOCK7 28mm | 1.5 | Chrome | |

| M14 LOCK7 35mm | 1.5 | Chrome, Red | |

| M12 LOCK7 35mm | 1.25 | Chrome | |

| Car Mark | |

| Size | Car Brand |

| M12xP1.5 |

TOYOTA, for honda, MITSUBISHI, MAZDA, DAIHATSU |

| M12xP1.25 | SUBARU, SUZUKI |

| M14xP1.5 | TOYOTA LAND CRUISER(100/200 SERIES), LEXUS(LS460/600h/500), for honda LEGEND(KB1, FK2, FK8), NISSAN GT-R |

|

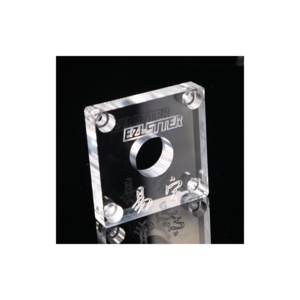

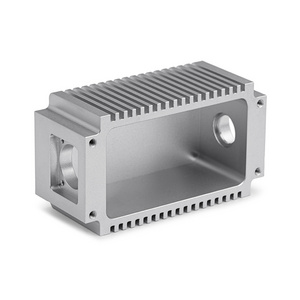

Our in-house Capabilities Includes

|

|

|

Our More Facilities |

|

|

|

About Us

KK TECH INC. Taiwan has been specializing custom CNC machine components for over 25 years, supplying high quality and high-performance CNC machine components and assemblies. Our manufacturing ranges from large CNC machine parts to dedicated ones such as auto parts, bicycle parts, pneumatic tools.

| Q1: What's your main products and market? |

|

A1-1:

We are specializing custom CNC Milling, CNC Turning. With our experienced teams and advanced facilities enable us to produce custom production parts according a client's demand. Our mainly product ranges are from Racing Auto Parts (ex.: Connecting Rod, Wheel Nuts, Oil Cap, Camshafts…), Bicycle (ex.: Hub, Bike Tools), Pneumatic Tools (ex.: Piston, Cylinder, Firing Pin) and Bone Plate for Trauma Treatment.

A1-2: Our products have been sold to worldwide such as USA, EU, Middle East, Japan, China and other countries. |

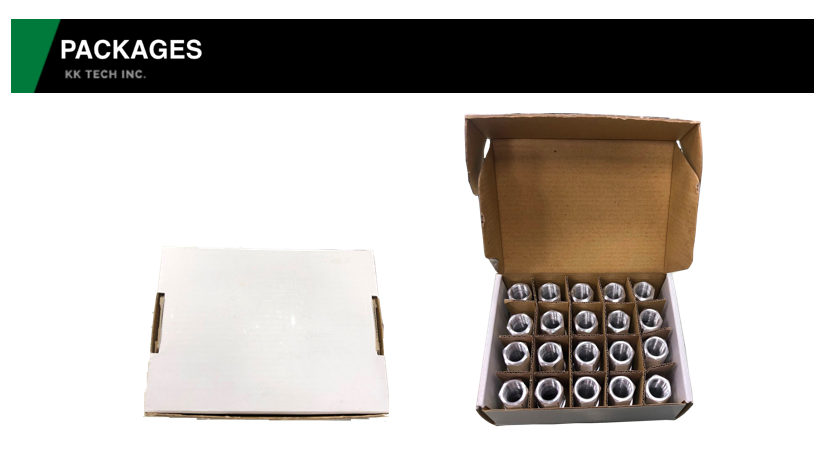

| Q2. What is the minimum order quantity and packing? |

|

A

2-1:

MOQ is subject to products' manufacturing process. However, a client may choose our standing parts with low MOQ.

A2-2: We provide alternative packing method for which products could packed by our standard packing method or packed as a client's requested. |

| Q3 : What is your payment method? |

| A3 : We offer T/T payment |

| Q4 : What is order lead time? |

| A4 : An order lead time is about 15-30 days after receiving deposit of down payment of an order. |

| Q5 : What material can you make? |

| A5 : Metal, Non-Metal, Plastic and so on |

| Q6 : What file can you accept? |

| A6 : PDF, JPG, DWG, IGES, STEP and so on |

| Q7 : What is the delivery time for the sample? |

| A7 : Sample is subject to the availability of sample, usually it is 5 to 25 days. |

| Q8 : Do you have machining center? |

| A8 : Yes, we have 3-axis milling, 4-axis milling and 5-axis milling |

| Q9 : What surface finish can you make? |

| A9 : Nickel plating, zinc plating, stoving varnish, anodic treatment and so on. |