Of course free for update whole life.

- Product Details

- {{item.text}}

Quick Details

-

Marketing Type:

-

New Product 2022

-

Application:

-

pre-sewing machine

-

Place of Origin:

-

Hubei, China

-

Brand Name:

-

YINENG TECH

-

Power:

-

25KW

-

Dimension(L*W*H):

-

5900*3250*2150

-

Weight:

-

4500 KG

-

Features:

-

computerized

-

Name:

-

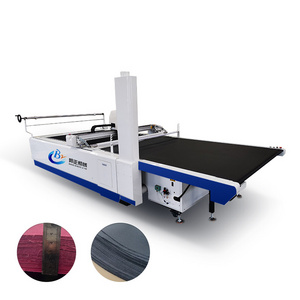

automatic fabric cutting machine

-

cutting speed:

-

70M/MIN

-

Functions:

-

auto cutting,feeding,picking

-

cutting method:

-

straight knife cutting

-

Usage:

-

pre-sewing machines

-

Power supply:

-

30KW

-

motors:

-

Panasonic servo motors & drivers

-

Feature:

-

high efficiency, more layers cut

-

Capacity:

-

60 sets per month

-

software:

-

CAD well compatible control system

Quick Details

-

Production Capacity:

-

50 sets per month

-

Voltage:

-

220V

-

Applicable Industries:

-

clothing, bags, shoes and hats, plush toys, car interior, home textiles, tents

-

Marketing Type:

-

New Product 2022

-

Application:

-

pre-sewing machine

-

Place of Origin:

-

Hubei, China

-

Brand Name:

-

YINENG TECH

-

Power:

-

25KW

-

Dimension(L*W*H):

-

5900*3250*2150

-

Weight:

-

4500 KG

-

Features:

-

computerized

-

Name:

-

automatic fabric cutting machine

-

cutting speed:

-

70M/MIN

-

Functions:

-

auto cutting,feeding,picking

-

cutting method:

-

straight knife cutting

-

Usage:

-

pre-sewing machines

-

Power supply:

-

30KW

-

motors:

-

Panasonic servo motors & drivers

-

Feature:

-

high efficiency, more layers cut

-

Capacity:

-

60 sets per month

-

software:

-

CAD well compatible control system

Product Description

Fully automatic professional fabric cutting machine non-woven cnc computer foam cutting machine

Auto cutting system & solution

Computerized automatic cutting system is specifically for the apparel, automotive interiors, home, bags, shoes, hats, home textiles, outdoor tents and other lager-scale production and processing enterprises that designed by our R& D team.The advantages of this equipment has solved high labor costs,material waste ,low productivity of the traditional cropping(hand shears, electric clippers), with computer typesetting automation, material saving ,high cutting precision, high productivity. This is a biggest change of the cloth industry history,this product has a significant role to enhance the strength of the company, improve work efficiency and cost savings.

Size Information

|

Model No.

|

KP-X1725

|

KP-X2025

|

KP-X2325

|

KP-X1733

|

KP-X2033

|

KP-X2333

|

|||||

|

Cutting

area

|

1700*2500

|

2000*2500

|

2300*2500

|

1700*3300

|

2000*3300

|

2300*3300

|

|||||

|

|

63"*98"

|

75"*98"

|

87"*98"

|

63"*130"

|

75"*130"

|

87"*130"

|

|||||

|

Cutting thickness

|

Max.70mm

|

|

|

|

|

|

|||||

|

Cutting materials

|

Garment cloth(knitted and woven),nonwoven fabric, plush toys, shoes, leather,sofa cushion,car interior decorative fabric, bras, composite fabric, car seat,ect.

|

|

|

|

|

|

|||||

|

Max cutting speed

|

70m/min(according cutting materials)

|

|

|

|

|

|

|||||

|

Cutting accuracy

|

≤±1mm

|

|

|

|

|

|

|||||

|

Power

|

30KW

|

|

|

|

|

|

|||||

|

Max speed

|

4500rpm/min

|

|

|

|

|

|

|||||

|

Cutting style

|

Straight Knife Continous Up-down Cutting

|

|

|

|

|

|

|||||

|

Cooling System

|

Auto Air Cooling System

|

|

|

|

|

|

|||||

|

Control System

|

Cutting control system Cut V4.0, well compatibility with any version CAD software

|

|

|

|

|

|

|||||

|

Software

|

YINENG Cutting program, multi-language software, auto change

|

|

|

|

|

|

|||||

|

Sharpen way

|

Sharpening stone System

|

|

|

|

|

|

|||||

|

Air pressure supply

|

0.55MPa 160L/min

|

|

|

|

|

|

|||||

|

Motor/driver

|

Japanese Panasonic Servo motors & Drivers

|

|

|

|

|

|

|||||

|

Machine power

|

AC380V/50HZ

|

|

|

|

|

|

|||||

|

Weight(kgs)

|

4.2T

|

4.5T

|

4.8T

|

4.8T

|

5T

|

5.5T

|

|||||

|

Machine out size(mm)

|

5900*2950*2150

|

5900*3250*2150

|

5900*3550*2150

|

7500*2950*2150

|

7500*3250*2150

|

7500*3550*2150

|

|||||

Machine Details

Control system cut V4.0 independently developed by Yinengtech support the mutual conversion of I notch and V notch. Easy operation and could connect with 98% CAD.

Electrical System:

The electrical system of the whole machine adopts an automatic control system , which effectively protects the stable operation of

the equipment through a large number of imported components, and ensures the cutting accuracy with high-precision and high- speed servo drive system.

the equipment through a large number of imported components, and ensures the cutting accuracy with high-precision and high- speed servo drive system.

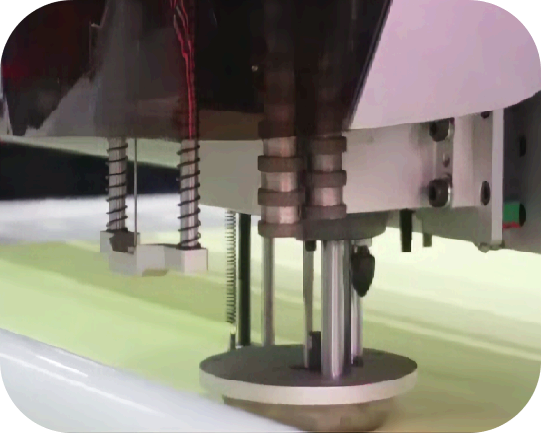

Machine head:

The cutting head is derived from the Japanese principle. The core components of the machine head have high hardness, light weight,long service life, high stability, and

effectively guarantee the cutting accuracy during high- speed operation.

effectively guarantee the cutting accuracy during high- speed operation.

Transmission system:

The transmission mode adopts high-precision rack and gear transmission system, which has high transmission accuracy, stable start

and stop, and long service life.

and stop, and long service life.

Whole structure machine body , strong for long life, annealing and stress-relieving treatment can ensure the body will not deform,

with stronger wear resistance and higher precision.

with stronger wear resistance and higher precision.

Company Introduction

YINENG TECH is an up-to-date industrial company, constantly oriented to the new technologies and able to provide cutting system for companies manufacturing apparel, technical fabric and composites. Founded in 2002, we become a leader in cutting machine market shortly. Company covers 70000 square meters and the fixed asset is RMB10 million CNY. Over 200 employees, more than 30 technicians serves here, over 100 sets of various manufacturing equipment, including: large scale forcing press machine, digital lathe, digital wire-electrode cutting equipment, various processing machines and equipment, etc.

YINENG Company owns national patents and proprietary technology with independent intellectual property right. We have a full set of manufacturing techniques and complete quality control devices. We can offer a complete suite of cutting solutions, always evolving, in order to increase efficiency and productivity, timely responding to the market changes and the new needs and requests. Nowadays, the main products include fabric automatic cutting machines, spreading machines, oscillating knife cutting machines, laser cutting machines and etc. Factory capacity reaches to 100 sets monthly, where the manufacturing process requires cutting of various amounts of layers and vagarious types of materials.

YINENG have been involved in a number of high profile cutting projects over the past 48 months including the China market and oversea market in Rwanda, Costa Rica, Argentina, Italy, Germany, Romania, Czech Republic, Slovakia, Vietnam, Turkey, Ukraine and etc.

Our Services

1) Training to install:

A.We will supply the machine with user manual in English for installing, operation, maintenance and trouble-shooting, and shall give technical guide by e-mail, fax, telephone/What’s App/ WeChat TeamViewer and so on when you meet some problems of installation, operation or adjusting.

B.You can come to YINENG factory for training. YINENG will offer professional guidance. Direct and face-to-face training. Here we have assembled equipment, all sorts of tools and testing facility. Training Time: 3 - 5 days ( The training for operation only. This does not means you can install the machine without our engineers on your factory site)

C.Our engineer will do a door-to-door instruction training service at your local site. We need your help to deal with the visa formality, prepaid traveling expenses and accommodation to us during the business trip and service period before their dispatch. It's better to arrange a translator for both of our engineers during the training period.

Installation,commissioning & Training Time: 12 -15 working days Remark: The charge of air ticket, accommodation expenses in your country will burden by your side.

2) Sales service management system, Standardized service management system, including: customer contact management, customer troubleshooting management, customer equipment regular maintenance, inspections management, customer records management and other accessories reviews.

Application

Exhibition

Packing & Shipping

Package Details

: Cutting Machine with water-proof film and standard wooden case

Port

: Shanghai

, Shenzhen, Ningbo.

Lead Time

: within 30 working days after deposit.

After Sales Service

1. Pre-sales service -- professional individual consultation

A.Free sample making: For free sample making/testing, please send your samples or products CAD Graphics to our company in China.Try before you buy.

B. Progressing solution design According to customer’s product processing requirement, we can design the unique solution that supports higher manufacturing efficiency and better processing quality for customer.

2. After-sales service – professional qualification and training

One-year after-sales service includes:

A. We will offer some of the parts for free in the first year.

B. In the first year, if the buyer needs our engineers to come to the local to fix some problems of the machine that they cannot fix by themselves; we will send our engineers for free. The buyer needs to pay the flights, housing and meals for the engineers in the local.

C. We will offer our service through email and phones and online service if the buyer needs any help on technical problems.

3. Installation and technical training includes:

A: We will send our engineers to customer’s factory for the local training and the installation, and this is free. The buyer needs to pay hotel and meals for the engineers in the local.

B: In-time golden services Responsive within 24 hours technical support provided for peace of mind.

4. Customer-orient maintenance cost control guide

A. Parts supply in time

we produce on order, Parts in warehouse for over 30 sets to guarantee the delivery of order and maintenance.

B. Release clients worry about big equipment service; supply the part with bare cost.

5. Sales service management system

Standardized service management system, including: customer contact management, customer troubleshooting management, customer equipment regular maintenance, inspections management, customer records management and other accessories reviews.

B. Progressing solution design According to customer’s product processing requirement, we can design the unique solution that supports higher manufacturing efficiency and better processing quality for customer.

2. After-sales service – professional qualification and training

One-year after-sales service includes:

A. We will offer some of the parts for free in the first year.

B. In the first year, if the buyer needs our engineers to come to the local to fix some problems of the machine that they cannot fix by themselves; we will send our engineers for free. The buyer needs to pay the flights, housing and meals for the engineers in the local.

C. We will offer our service through email and phones and online service if the buyer needs any help on technical problems.

3. Installation and technical training includes:

A: We will send our engineers to customer’s factory for the local training and the installation, and this is free. The buyer needs to pay hotel and meals for the engineers in the local.

B: In-time golden services Responsive within 24 hours technical support provided for peace of mind.

4. Customer-orient maintenance cost control guide

A. Parts supply in time

we produce on order, Parts in warehouse for over 30 sets to guarantee the delivery of order and maintenance.

B. Release clients worry about big equipment service; supply the part with bare cost.

5. Sales service management system

Standardized service management system, including: customer contact management, customer troubleshooting management, customer equipment regular maintenance, inspections management, customer records management and other accessories reviews.

automatic fabric flower pattern cutting machine for garment industry

Hot Searches