- Product Details

- {{item.text}}

Quick Details

-

Power:

-

According to filter size

-

Weight:

-

700000 kg

-

Dimension(L*W*H):

-

According to filter size

-

Name:

-

HVPF vertical automatic press filter

-

Capacity:

-

Customized

-

Certification:

-

CE, ISO 9001, IS0 14001

-

Application:

-

Solid-liquid separation

-

Material:

-

Carbon steel, stainless steel or others

-

Packing:

-

Seaworthy package

-

Life:

-

More than 30 years

-

After Warranty Service 1:

-

Spare parts

-

After Warranty Service 2:

-

Field maintenance and repair service

Quick Details

-

Place of Origin:

-

Shandong, China, Shandong, China (Mainland)

-

Brand Name:

-

Toncin

-

Voltage:

-

According to filter size

-

Power:

-

According to filter size

-

Weight:

-

700000 kg

-

Dimension(L*W*H):

-

According to filter size

-

Name:

-

HVPF vertical automatic press filter

-

Capacity:

-

Customized

-

Certification:

-

CE, ISO 9001, IS0 14001

-

Application:

-

Solid-liquid separation

-

Material:

-

Carbon steel, stainless steel or others

-

Packing:

-

Seaworthy package

-

Life:

-

More than 30 years

-

After Warranty Service 1:

-

Spare parts

-

After Warranty Service 2:

-

Field maintenance and repair service

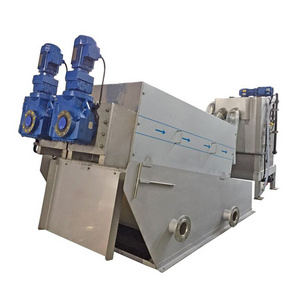

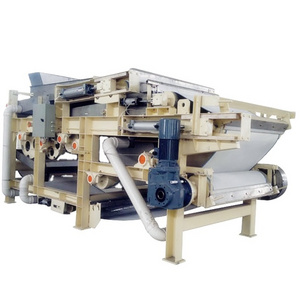

HVPF Vertical Automatic Tower Press Filter

HVPF vertical automatic press filter is the most advanced filter that the world has ever get. Vacuum has a limit, but Pressure not. HVPF vertical automatic press filter use air or water to form a huge pressure difference on both sides of filter cloth to achieve very efficient separation of solid and liquid. As filter plate is closed, slurry is pumped into filter chamber through slurry pipes. Part of filtrate then enter the filtrate chamber through filter cloth because of gravity. Then high pressure water force rubber diaphragm to extrude filtrate from filter cake. When these process is finished, the driver run filter clothes and filter cakes is discharged from both sides of filter cloth.

|

Model

|

Filtrating Area(m2) |

Overall Dimension m (L×W×H) |

Filtrating Plate Quantity |

Volume(m3)

|

Weight (T) |

Hydraulic power (KW) |

Filter plate specification (mm) |

Width of filter cloth |

|

HVPF-1 |

1 |

2.5×1.5×2.0 |

2 |

0.05 |

8 |

7.5 |

1000*550 |

0.7 |

|

HVPF-2 |

2 |

2.5×1.5×2.2 |

4 |

0.09 |

9 |

7.5 |

||

|

HVPF-3 |

3 |

3.5×2.5×2.2 |

2 |

0.16 |

14 |

11 |

1750*900 |

1.05 |

|

HVPF-4 |

4 |

3.5×2.5×2.3 |

4 |

0.27 |

15 |

11 |

||

|

HVPF-9 |

9 |

3.5×2.5×2.5 |

6 |

0.41 |

16 |

11 |

||

|

HVPF-12 |

12 |

3.5×2.5×2.7 |

8 |

0.54 |

17 |

11 |

||

|

HVPF-15 |

15 |

3.5×2.5×2.9 |

10 |

0.68 |

18 |

11 |

||

|

HVPF-18 |

18 |

3.5×2.5×3.1 |

12 |

0.81 |

19 |

11 |

||

|

HVPF-21 |

21 |

3.5×2.5×3.3 |

14 |

0.95 |

21 |

11 |

||

|

HVPF-24 |

24 |

3.5×2.5×3.4 |

16 |

1.08 |

22 |

11 |

||

|

HVPF-27 |

27 |

3.5×2.5×3.6 |

18 |

1.22 |

23 |

11 |

||

|

HVPF-15 |

15 |

5.1×3.7×3.3 |

6 |

0.68 |

37 |

22 |

2500*1020 |

1.15 |

|

HVPF-20 |

20 |

5.1×3.7×3.6 |

8 |

0.9 |

39 |

22 |

||

|

HVPF-25 |

25 |

5.1×3.7×3.9 |

10 |

1.13 |

42 |

22 |

||

|

HVPF-30 |

30 |

5.1×3.7×4.2 |

12 |

1.35 |

43 |

22 |

||

|

HVPF-35 |

35 |

5.1×3.7×4.5 |

14 |

1.58 |

44 |

22 |

||

|

HVPF-40 |

40 |

5.1×3.7×4.8 |

16 |

1.8 |

45 |

22 |

||

|

HVPF-45 |

45 |

5.1×3.7×5.1 |

18 |

2.03 |

46 |

22 |

||

|

HVPF-50 |

50 |

5.1×3.7×5.4 |

20 |

2.25 |

48 |

22 |

||

|

HVPF-60 |

60 |

6.9×4.5×5.4 |

10 |

2.7 |

97 |

37 |

4010*1500 |

1.7 |

|

HVPF-72 |

72 |

6.9×4.5×5.8 |

12 |

3.24 |

100 |

37 |

||

|

HVPF-84 |

84 |

6.9×4.5×6.2 |

14 |

3.78 |

104 |

37 |

||

|

HVPF-96 |

96 |

6.9×4.5×6.5 |

16 |

4.32 |

110 |

37 |

||

|

HVPF-108 |

108 |

6.9×4.5×6.9 |

18 |

4.86 |

112 |

37 |

||

|

HVPF-120 |

120 |

6.9×4.5×7.2 |

20 |

5.4 |

118 |

37 |

||

|

HVPF-132 |

132 |

6.9×4.5×7.6 |

22 |

5.94 |

120 |

37 |

||

|

HVPF-144 |

144 |

6.9×4.5×7.9 |

24 |

6.48 |

123 |

37 |

||

|

HVPF-156 |

156 |

6.9×4.5×8.3 |

26 |

7.02 |

126 |

37 |

||

|

HVPF-168 |

168 |

6.9×4.5×8.6 |

28 |

7.56 |

130 |

37 |

||

|

HVPF-144 |

144 |

9.2×5.5×6.8 |

18 |

6.48 |

142 |

67 |

6020*1500 |

1.7 |

|

HVPF-162 |

162 |

9.2×5.5×7.2 |

18 |

7.29 |

147 |

67 |

||

|

HVPF-180 |

180 |

9.2×5.5×7.5 |

20 |

8.1 |

150 |

67 |

||

|

HVPF-198 |

198 |

9.2×5.5×7.8 |

22 |

8.91 |

160 |

67 |

||

|

HVPF-216 |

216 |

9.2×5.5×8.2 |

24 |

9.72 |

166 |

67 |

||

|

HVPF-234 |

234 |

9.2×5.5×8.5 |

26 |

10.53 |

172 |

67 |

||

|

HVPF-252 |

252 |

9.2×5.5×8.8 |

28 |

11.34 |

180 |

67 |

||

|

HVPF-270 |

270 |

9.2×5.5×9.2 |

30 |

12.15 |

190 |

67 |

Work Principle

(1) Filtering stage: when the filter plate closed, the slurry is pumped into filter chamber through slurry pipe. The filtrate enter into the filtrate chamber through filter cloth, and get into filtrate manifold through filtrate tube, meanwhile, the filter cake is formed in the filter chamber.

(2) Extrusion: the high pressure water enters into membrane through the tube and make the membrane extrudes towards filter cake to make the filtrate of the filter cake extrude out.

(3) Cake w ashing : the washing water is pumped into filter chamber by slurry pipe, after washing the cake and through cloth flow into the discharge pipes.

(4) Air drying: the air flow with water go through the filter cake, which can reduce the moisture of filter cake to the maximum and empty the filtrate chamber at the same time.

(5) Filter cake discharge : when the drying process finished, the driving parts drive the filter cloth to run and the filter cake discharges from both sides of filter cloth.

(1) The structure of filter plate adopts guide device to make sure the smoothly running.

(2) It can continuously automatically realize the operation in the process of filtering, extrusion, washing, drying, discharging and filter cloth regeneration.

(3) The filter pressure can reach 2.0 Mpa. Especially have good effect on various sticky tiny materials and low moisture of filter cake.

(4) the key point of this type of equipment is no matter how much pressure it can get but safety. Hydraulic pressure system is adopted just to make sure every plate locks well. Every nozzle and diaphragm are designed and inspected very carefully to keep the equipment safe when high pressure water gets into chambers.

(5) The equipment adopts PLC + touch screen + automatic valves, and labor input is lower..

(6) Compact structure covers less floor area

HVPF vertical automatic press filter can be applied in mining, metallurgy, chemical industry, pharmacy and food industries. It is a kind of high capacity, energy-saving, automatic solid-liquid separation machine.

Supply Range and Requirements on Local Installation :

(1) It consists of host, hydraulic station, water station, cleaning system and control system.

(2) This machine must be installed on solid flat reinforced concrete, or steel rack. Consult foundation size and related dimension to installation sketch map and foundation chart. The depth of groundwork is determined by customers according to real conditions. Host should be suspended by professional technicians, avoid the equipment from impacting or scratching. Utilize grad enter to adjust the host during installation, then install other equipments during fastening the host.

(3) A ir supply : granule less than 5 um, pressure 0.5-0.6MPa, Air Volume: take assemble chart as reference

(4) Water supply: max. solid contents 5ppm, solid granule less than 50um, pressure 3.5-6bar, take assemble chart as reference for supply volume

(5) Power supply: 3 phase/380V±5%, single phase/220V±5%,50Hz

(6) Working Environment: working environment requirements for this machine , not freeze.