- Product Details

- {{item.text}}

Quick Details

-

Power:

-

depend

-

Dimension(L*W*H):

-

depend

-

Weight:

-

800 KG

-

Material:

-

SS304 / SS316

-

Heat Type:

-

Steam / Electricity / Direct Dire

-

Control system:

-

PLC

-

Thickness of Tanks:

-

Inner 3mm External 2mm

-

Insulation material:

-

Rockwool

-

Cladding:

-

SUS304 / Red Copper

-

Usage:

-

Brewery Pub Hotel

-

After Warranty Service:

-

Field maintenance and repair service

-

Local Service Location:

-

Turkey

-

After-sales Service Provided:

-

Field installation, commissioning and training

Quick Details

-

Place of Origin:

-

Shandong, China

-

Brand Name:

-

Tonsen

-

Voltage:

-

220V, 400V or customized

-

Power:

-

depend

-

Dimension(L*W*H):

-

depend

-

Weight:

-

800 KG

-

Material:

-

SS304 / SS316

-

Heat Type:

-

Steam / Electricity / Direct Dire

-

Control system:

-

PLC

-

Thickness of Tanks:

-

Inner 3mm External 2mm

-

Insulation material:

-

Rockwool

-

Cladding:

-

SUS304 / Red Copper

-

Usage:

-

Brewery Pub Hotel

-

After Warranty Service:

-

Field maintenance and repair service

-

Local Service Location:

-

Turkey

-

After-sales Service Provided:

-

Field installation, commissioning and training

Shandong Tonsen Equipment Co., Ltd. is an international comprehensive enterprise specializing in R&D,production,technical support and services for beer equipment and wine equipment .

We provide complete beer brewing solutions that include: malt handling system, brew house system, beer fermenting/storage system, cooling system, cleaning system, control system, package line.

Tonsen brewing equipment has been exported to more than 30 countries, which include USA, Canada, Australia, Japan, UK, France, Germany, Denmark,Norway,Agentina,Russia etc.

Tonsen Tu

rnkey Brewery Eu

ipment

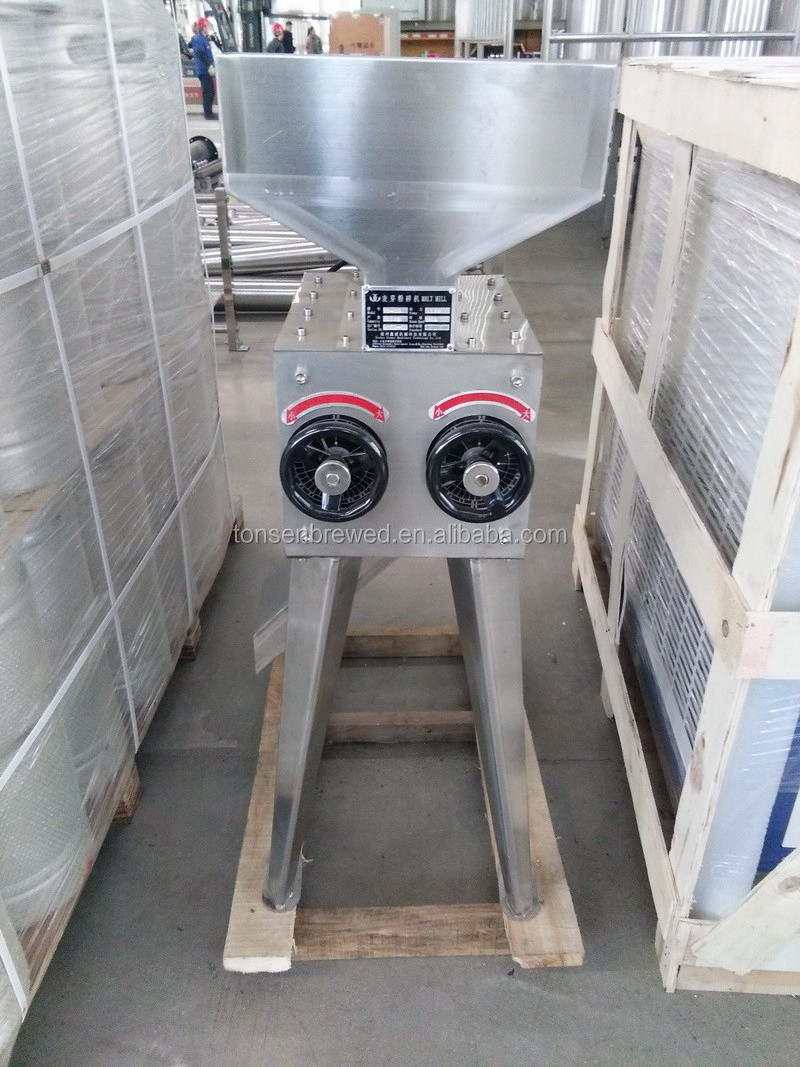

Description: CE or UL listed Motor, Double roller, distance adjustable, stainelss steel 304 material.

2----Brew House System

2-4 vessles or combined system.

-Capacity 100L-5000L, 1bbl-40bbl.

- Steam heated, electrical heated or natural gas

-Mash tun with mixer, steam jacket, VFD motor, insulated 80mm. Stainelsss steel 304.

-Lauter tun with rake system, milled false bottom, sparging spray ring,VFD motor, insulated 80mm.

-Boiling kettle with steam jacket, inner heated option, insulated 80mm. Stainelsss steel 304.

-Whirlpool with Tangential whirlpool inlet. insulated 80mm. Stainelsss steel 304.

-Insulated HLT and CLT with the pipelines and pumps

-External grant, hops back, heat exchanger.Wort oxygenation system, working platform.

-All the necessary pipelines and pumps

3--- -Fermenter&BBT System

-Interior shell thickness 3-6mm, Exterior shell=2mm

-100% TIG welding with pure argon gas shield

-Interior finish: pickled and passivated, external polished, 80mm insulated

-Test pressure 3 bar, working pressure 1.5 bar

-Glycol zones (Both on side and concial/bottom)

-60°conical bottom for Fermener, Shadow less side man way

-Racking arm, Sample valve, Pressure relief valve on the top, Dry hopping on the top

-Mechanical relief valve 3 bar on CIP arm with pressure gauge

4.----Cooling System

Description: Air type chiller + Ice water tank or Glycol tank

Capacity: 3HP, 5HP, 7HP, 10HP, 15HP, 20HP, 30HP+ 500L-20000L tank

Brand: Copeland, SANYO

5----Control System

-PID or PLC system

-SIEMENS program S7-200, Siemens touch screen.

-Penumatic valves for optional

5----Canning line, Kegging line

-Double station Kegging line.

-Small capacity Canning line.

1) All tanks will be packed with soft protection material and mounted on steel frame

2) All accessories and spare parts will be packed with soft protection material and then put into iron box

3) After loaded into containers, all equipment will be fixed to the containers.