- Product Details

- {{item.text}}

Quick Details

-

Brand Name:

-

Dafu

-

Voltage:

-

Local Requirement

-

Power:

-

85-365 Kw

-

Dimension(L*W*H):

-

25*12*6m

-

Weight:

-

120000 kg

-

Features:

-

Environmental

-

Warranty:

-

12 Months

-

Advantages:

-

Low price, high efficiency , long service time

-

Technical support:

-

All round technical support and one stop services

-

Fuel:

-

Oil Gas Coal etc.

-

Final Product:

-

High quality, high stability

-

Installation:

-

Engineers approved

-

Calcination system:

-

Fulidized Furnace

-

Calcination temperature:

-

160-220

-

Calcination time:

-

40 minutes

-

Manufacturer:

-

Good price

Quick Details

-

Marketing Type:

-

New Product

-

Application:

-

Gypsum Powder Production, Making plaster of paris

-

Place of Origin:

-

Henan, China

-

Brand Name:

-

Dafu

-

Voltage:

-

Local Requirement

-

Power:

-

85-365 Kw

-

Dimension(L*W*H):

-

25*12*6m

-

Weight:

-

120000 kg

-

Features:

-

Environmental

-

Warranty:

-

12 Months

-

Advantages:

-

Low price, high efficiency , long service time

-

Technical support:

-

All round technical support and one stop services

-

Fuel:

-

Oil Gas Coal etc.

-

Final Product:

-

High quality, high stability

-

Installation:

-

Engineers approved

-

Calcination system:

-

Fulidized Furnace

-

Calcination temperature:

-

160-220

-

Calcination time:

-

40 minutes

-

Manufacturer:

-

Good price

Widely Used Quality Assurance Gypsum powder production plant

Intr oduction:

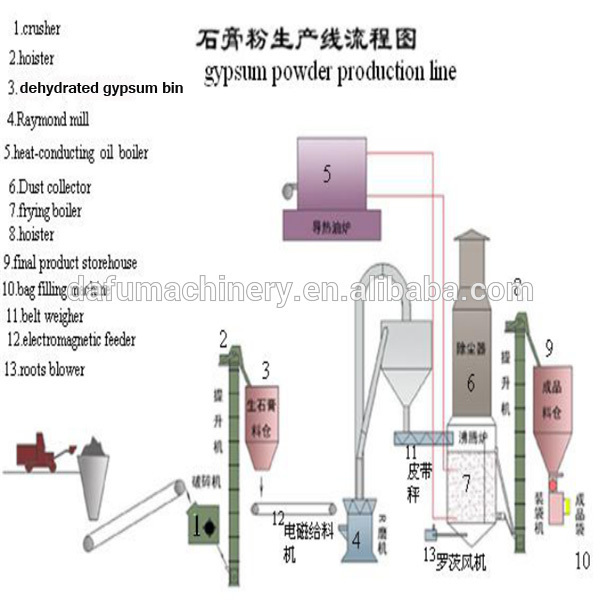

Gypsum ore →first breaking →second breaking →grinding →calcining →aging →finished products(CaSO4·1/2H2O )

With the development of gypsum industry, there is a large demand for quantity and high quality of gypsum powder.Therefore, high level of gypsum powder production technology is required. In the process of gypsum powder production, drying and dewatering is the key link, which is

also the most difficult one to control. In order to solve this problem, we develop a new type

of drying and dewatering equipment---ebullience calciner,which is produced based on the exploring of the gypsum production filed. Following is the brief introduction of the gypsum

production technology and ebullience calciner working principle.

Characteristics:

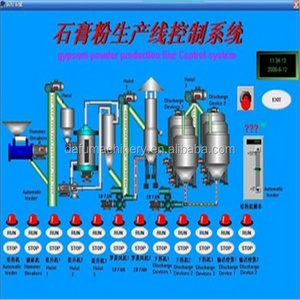

It adopts the advanced hot oil drying system and PLC electrical controlling system. The daily output is from 50 tons to 500 tons,and the products are of high quality and wide usages:making the gypsum board, the gypsum block or applied in the medicine. We can make out a whole set

of equipment with the best quality and practicality, the most reasonable price and according to the customers requirements, and give you a satisfactory turn-key project.

Concept of technique

Crusher grinds large gypsum into small granules less than25mm.After storage and measurementwith weigh

belt,transfer them into Raymond mill for milling.Transfer qualified calcined gypsumpowder to clinker bin for

storage or to board-manufacturing workshop for usage.

Specifications of the gypsum powder line

|

Capacity T/year |

Ton/hour |

Raw gypsum rock consumption T/year |

Heat supplying way |

Boiling furnace size |

|

20,000 |

2.7 |

24,000 |

Heat conductive oil or steam

|

4.5M×1.0M×1.2M |

|

30,000 |

4.2 |

36,000 |

4.5M×1.2M×1.4M |

|

|

50,000 |

6.9 |

60,000 |

4.5M×1.4M×1.6M |

|

|

60,000 |

8.3 |

72,000 |

4.5M×1.6M×1.8M |

|

|

80,000 |

11.11 |

96,000 |

4.5M×1.8M×2.0M |

|

|

100,000 |

13.88 |

120,000 |

4.5 M×2.0 M×2.2 M |

|

|

150,000 |

20.83 |

180,000 |

4.5 M×2.2 M×2.4 M |

|

|

200,000 |

27.77 |

240,000 |

4.5 M×2.4 M×2.6 M |

|

|

300,000 |

41.66 |

360,000 |

4.5 M×2.6 M×2 |

Note: The specifications above is just for your reference, pls kindly tell us your capacity, so we can customize it for you!

Ebullience calciner(including Roots blower )

Electrostatic dust collector

Heat-conducting oil boiler

B esides the equipment mentioned above, design for the entire production line and auxiliary equipment election are provided, and technical engineers would be sent to the customer’s site for installation and debugging machine to guarantee qualified product.

How to decide the size/type of machinewe need?

Kindly tell us the following information if you are interested in our machine:

1. The daily output capacity or daily output capacity you need?

2. The fuel used in gypsum powder production line?

We can manufacture customized output capacity gypsum board prodcution line for the clients.

welcom to customize