- Product Details

- {{item.text}}

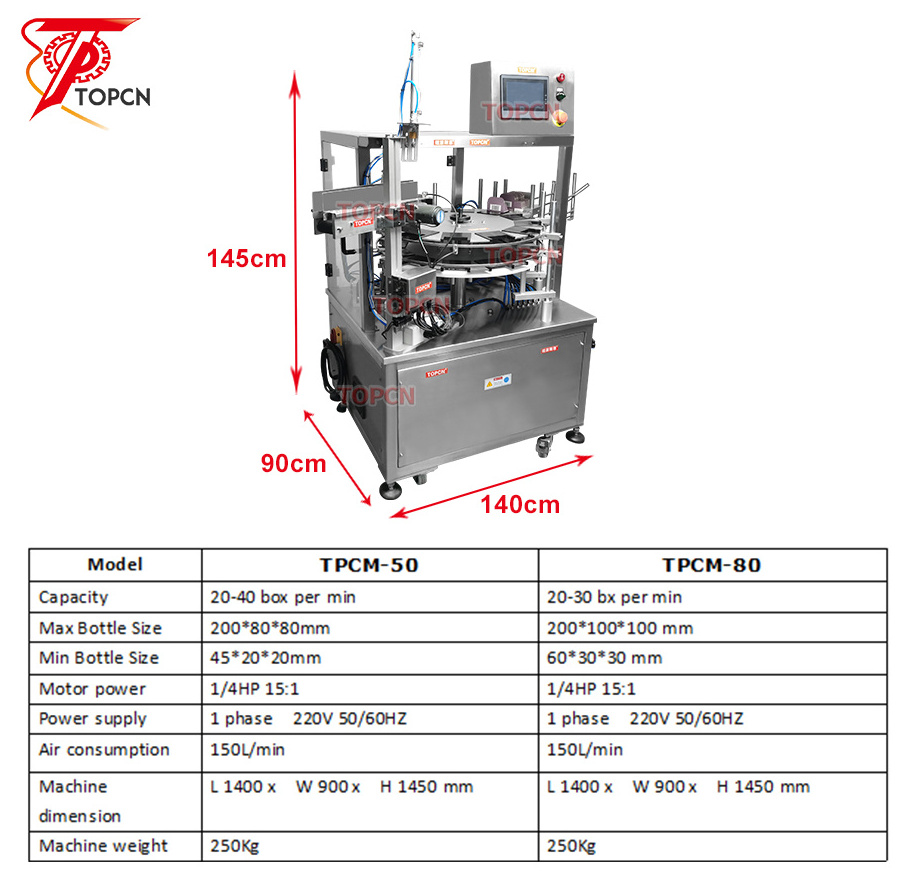

Quick Details

-

Place of Origin:

-

Guangdong, China

-

Dimension(L*W*H):

-

140*90*145cm

-

Weight:

-

250 KG

-

Core Components:

-

Others

-

After-sales Service Provided1:

-

Engineers available to service machinery overseas

-

After-sales Service Provided2:

-

Field installation, commissioning and training

-

After-sales Service Provided4:

-

Video technical support

-

After-sales Service Provided5:

-

Online support

-

Product name:

-

Vertical Box Packing Machine

-

Production Capacity:

-

20-40 box per min

-

Motor power:

-

1/4HP 15:1

-

Air consumption:

-

150L/min

-

Max Bottle Size:

-

200*80*80mm

-

Min Bottle Size:

-

45*20*20mm

Quick Details

-

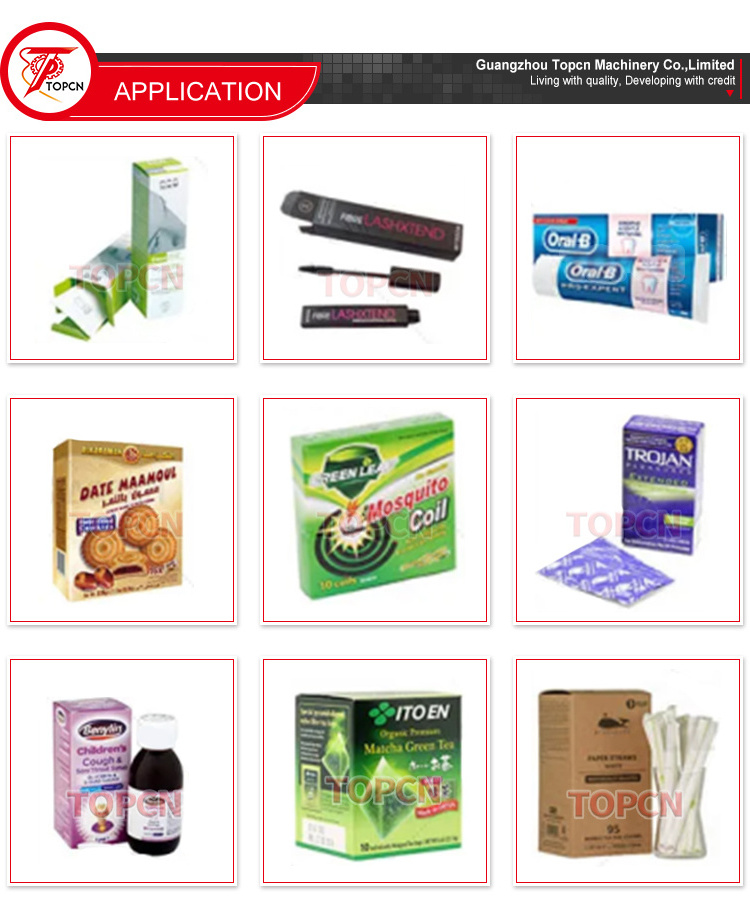

Application:

-

Food, Medical, Chemical, Cigarettes

-

Packaging Material:

-

Paper

-

Voltage:

-

220V/110V

-

Place of Origin:

-

Guangdong, China

-

Dimension(L*W*H):

-

140*90*145cm

-

Weight:

-

250 KG

-

Core Components:

-

Others

-

After-sales Service Provided1:

-

Engineers available to service machinery overseas

-

After-sales Service Provided2:

-

Field installation, commissioning and training

-

After-sales Service Provided4:

-

Video technical support

-

After-sales Service Provided5:

-

Online support

-

Product name:

-

Vertical Box Packing Machine

-

Production Capacity:

-

20-40 box per min

-

Motor power:

-

1/4HP 15:1

-

Air consumption:

-

150L/min

-

Max Bottle Size:

-

200*80*80mm

-

Min Bottle Size:

-

45*20*20mm

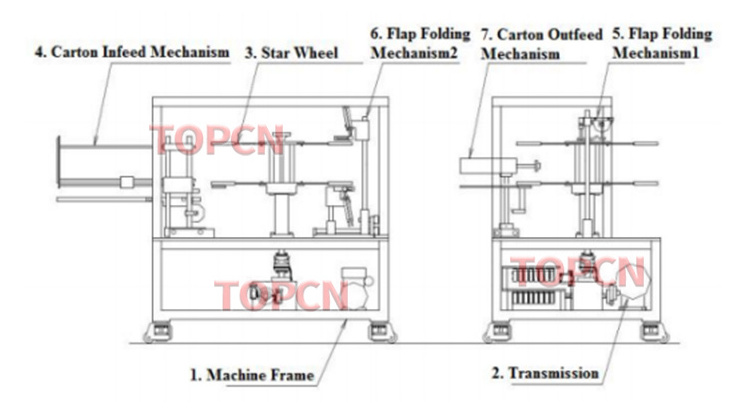

Products Description

Fully Automatic Cosmetic Facial Cream Ointment Round Jars Bottle Small Carton Packing Vertical Cartoning Machine will suck carton, feed the carton into the star wheel, and the carton will be rotated by the star wheel to the printer position to print the code, then the worker will put the product into the carton, then the carton will be rotated by the star wheel to the flap folding mechanism to finish the flaps folding, then the star wheel will rotate the carton to the carton out feed mechanism to discharge.

Machine mainly consists of:

1. Machine Frame

2. Transmission

3. Star Wheel

4. Carton In feed Mechanism

5. Flap Folding Mechanism1

6. Flap Folding Mechanism2

7. Carton Out feed Mechanism

|

Model

|

TPCM-50

|

TPCM-80

|

|

|

||

|

Capacity

|

20-40 box per min

|

20-30 bx per min

|

|

|

||

|

Max Bottle Size

|

200*80*80mm

|

200*100*100 mm

|

|

|

||

|

Min Bottle Size

|

45*20*20mm

|

60*30*30 mm

|

|

|

||

|

Motor power

|

1/4HP 15:1

|

1/4HP 15:1

|

|

|

||

|

Power supply

|

1 phase 220V 50/60HZ

|

1 phase 220V 50/60HZ

|

|

|

||

|

Air consumption

|

150L/min

|

150L/min

|

|

|

||

|

Machine dimension

|

L 1400 x W 900 x H 1450 mm

|

L 1400 x W 900 x H 1450 mm

|

|

|

||

|

Machine weight

|

250Kg

|

250Kg

|

|

|

||

1. The carton will be sucked by the vacuum box sucking device on the carton in feed mechanism, and it will be fed into the mould of the star wheel, then the bottom cylinder will fold the small bottom flaps.

2. Print the batch number on the carton.

3. Put the product into the carton.

4. The rotary cylinder coupling with the flap folding rod on the flap folding mechanism1 will fold the small top flaps.

5. When the carton goes into this station, the flap blocking cylinder on the flap folding mechanism2 will block the big flap, the flap folding cylinder will fold the big flap into the carton, then the flap pressing cylinder will flatten the big flap.

6. When the carton goes to this station after flap folding finished, the box pushing cylinder will push the finished product out of the star wheel.

Vertical cartoning machine advanced PLC control system combined with 5.7 color touch screen control panel can easily set and change packaging parameters.

Bottle Carton Packing Machine with the long boxes' feeding shelf design, you can place up to 1000 pcs boxes, the machine will alarm and stop automatically when the boxes are going to running out.

Miain turntable for running the turret and deliver the carton to different working station

Folded paper insert into the box.

Design different feeding type for different products.

Related Products

Full Automatic Production Line

* Can automatically

filling liquid

, capping bottle caps and labeling stickers at the same time.

* With conveyor, it can help to save a lot of labor.

Our Services

■

1. A step-by-step free English manual and operation video to easily know how to operate the machine.

■

2. Our senior engineers are skillful and fluent in English. They have rich oversea experiences and are available to oversea services. Below with some pictures our engineers trained customers how to install and operate the machines.

Customer Evaluation

Hot Searches