- Product Details

- {{item.text}}

Quick Details

-

Power:

-

35KW for extruder , 80kw for entire line

-

Weight:

-

3 tons

-

Dimension(L*W*H):

-

21*2.8*3.0 m for whole line

-

Warranty:

-

2 Years

-

Material:

-

Stainless Steel

-

Motor:

-

Simens

-

Inverter:

-

Delta, ABB, LG, FUJI,OMRON,customizable

-

Relays:

-

Weidmuller, Schneider, customizable

-

Experience of engineers:

-

15-20 years

-

Product name:

-

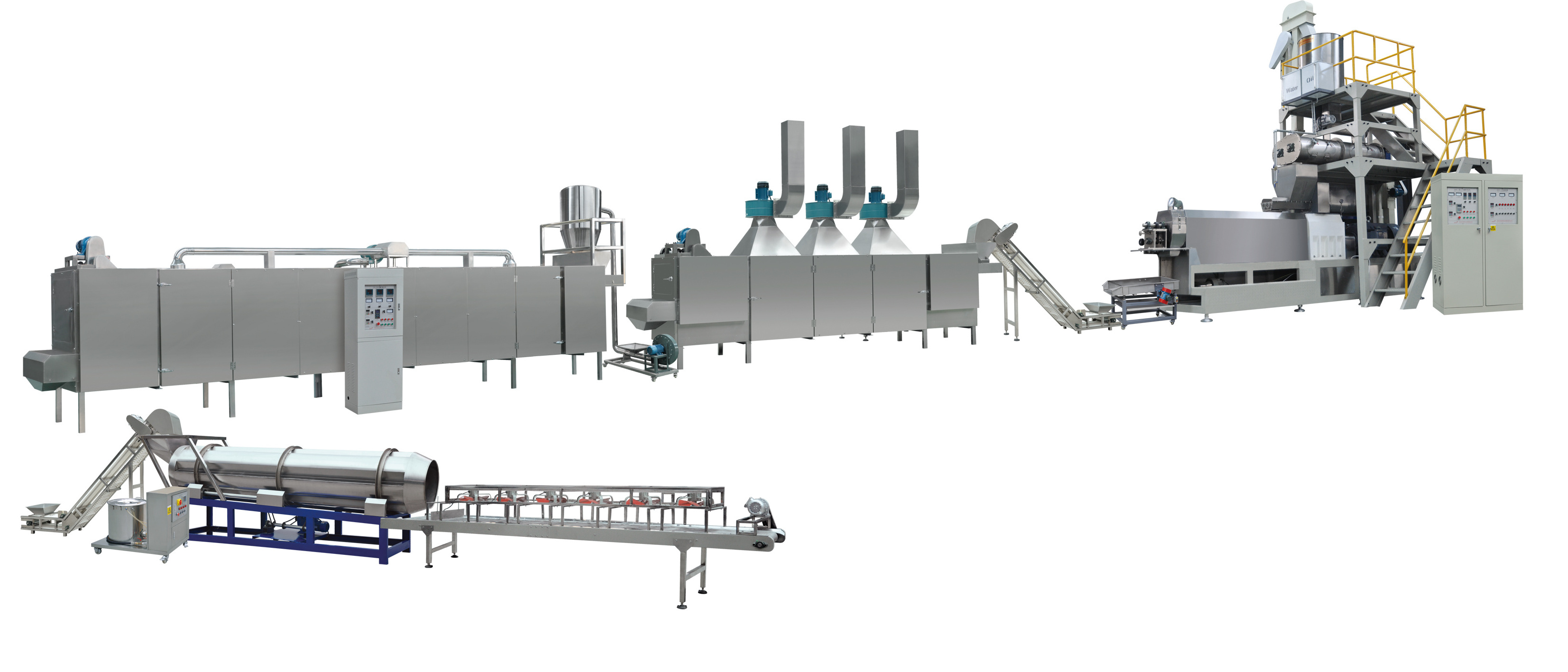

fish flake food making machine for sale

-

Origin:

-

Jinan, China

-

Automatic:

-

high automatic

-

Feeding type:

-

various type pet food

-

Capacity:

-

100kg/h; 200kg/h; 300kg/h;500kg/h;1000kg/h

-

After Warranty Service:

-

Video technical support, Online support, Spare parts, Field maintenance and repair service

-

Local Service Location:

-

None

-

Certification:

-

CE BV TUV GOST

Quick Details

-

Place of Origin:

-

Shandong, China

-

Brand Name:

-

Zhuoheng

-

Voltage:

-

380V

-

Power:

-

35KW for extruder , 80kw for entire line

-

Weight:

-

3 tons

-

Dimension(L*W*H):

-

21*2.8*3.0 m for whole line

-

Warranty:

-

2 Years

-

Material:

-

Stainless Steel

-

Motor:

-

Simens

-

Inverter:

-

Delta, ABB, LG, FUJI,OMRON,customizable

-

Relays:

-

Weidmuller, Schneider, customizable

-

Experience of engineers:

-

15-20 years

-

Product name:

-

fish flake food making machine for sale

-

Origin:

-

Jinan, China

-

Automatic:

-

high automatic

-

Feeding type:

-

various type pet food

-

Capacity:

-

100kg/h; 200kg/h; 300kg/h;500kg/h;1000kg/h

-

After Warranty Service:

-

Video technical support, Online support, Spare parts, Field maintenance and repair service

-

Local Service Location:

-

None

-

Certification:

-

CE BV TUV GOST

Product Description

1). All fish food equipments are made of stainless steel.

2). The fish food whole line fully continuous and automatic.

3). Zhuoheng provide basic fish food formula according to your require.

4). The final fish food shapes and sizes can be various by changing the mould.

5). Supply different size mould free of charge.

6). Packing machine could be supplied to work with the fish feed production line (depending on your require)

2). The fish food whole line fully continuous and automatic.

3). Zhuoheng provide basic fish food formula according to your require.

4). The final fish food shapes and sizes can be various by changing the mould.

5). Supply different size mould free of charge.

6). Packing machine could be supplied to work with the fish feed production line (depending on your require)

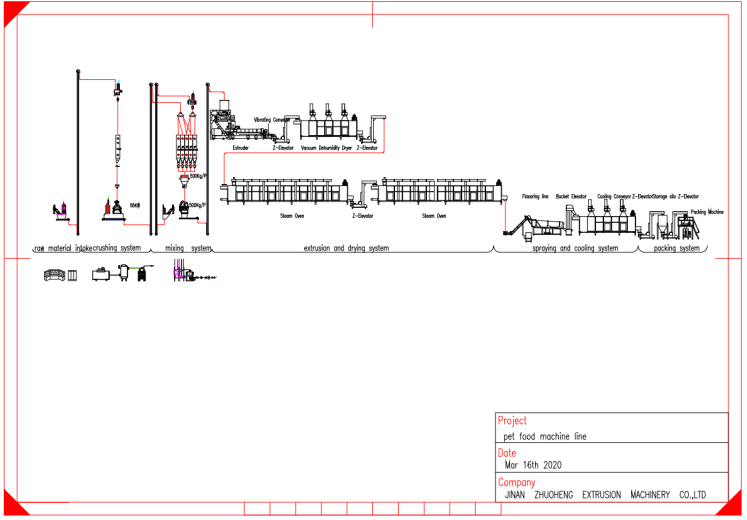

Flow Chart

.

Grinding→mixing→extruding→drying→flavoring→cooling→packaging

Our engineer could design the layout drawing according to your dimension of the factory for the fish feed machines.

Our engineer could design the layout drawing according to your dimension of the factory for the fish feed machines.

Product Paramenters

|

Model

|

Installed Power(kw)

|

Power Consumption (kw)

|

Capacity(kg/h)

|

Dimension(m)

|

|

ZH65

|

110kw

|

70kw

|

120-150

|

25*3*3

|

|

ZH70

|

138kw

|

95kw

|

200-250

|

28*3*3

|

|

ZH85

|

240kw

|

160kw

|

500

|

30*3*3

|

|

ZH95

|

330kw

|

230kw

|

1000-1200

|

50*3*3

|

|

ZH115

|

400kw

|

280kw

|

2000

|

60*6*15

|

|

ZH135

|

500kw

|

350kw

|

3000

|

60*6*20

|

Raw Material

Rice flour, corn flour, wheat flour, low temperature soya flakes meal, rice bran , wheat bran, fish powder, bone powder etc.

Fish feed samples made by our machines

fish feed pellet /color customized/floating and sinking type/length customized

diameter from 0.2mm to 20mm

diameter from 0.2mm to 20mm

Equipment list in the fish feed production line:

mixer→screw conveyor→twin screw extruder→air conveyor→dryer→hoister→flavoring drum and oil sprayer→cooling machine→packing machine

Blender Mixer

Blend Mixer is a high standard two-way ribbon mixing machine. It includes material tank, screw mixing paddles and drive parts.

Screw

mixing paddles are the double deck structure or three-tier structure. Outside of the screw paddles collecting and mixing the raw

materials flour from two borders area to the center area. Meanwhile, the inside of the screw mixing paddles conveying and mixing the flour materials from center to the borders. Then it makes the convective mixing to ensure the flour materials mixing evenly with high efficiency.

Double screw extruder

Double Screw Extruder Unit is the high standard and professional extrusion machinery unit. It’s consist of bucket elevator, Storage Silo, material conveyor, conditioner, feeder,extruder, electric controller and operation platform. The extruder includes drive system, extrusion system, cutting system,heating system, lubricating system and extraction steam system. Conditioner is designed as the advanced technology biaxial differential modulator. It can higher the materials temperature,make flour materials softer, lower the materials’ friction . Thus reducing the extrusion power consumption, increasing the

output, improving the stability of the extruder operation, prolonging life of t the whole extruder unit.

output, improving the stability of the extruder operation, prolonging life of t the whole extruder unit.

Hot Air criculation Baking oven

Heat With Infrared Ray Heating Tube, Raise And Lower Down Temperature Quickly, Small Heat Inertia And High Heat Efficiency.

Adjustable Transit Speed Of Net Belt With Accurate Temperature Control Device. Sliding Board Bottom Of Dryer For Easy Cleaning. Hot Wind Cycle Device Makes Heating Energy Equally In The Dryer

Double-Roller Chain And Chain Drive Make Stable And Smooth Running.

Adjustable Transit Speed Of Net Belt With Accurate Temperature Control Device. Sliding Board Bottom Of Dryer For Easy Cleaning. Hot Wind Cycle Device Makes Heating Energy Equally In The Dryer

Double-Roller Chain And Chain Drive Make Stable And Smooth Running.

Single drum flavoring line

It’s consist of hoistor, drum machine, flavoring machine and oil sprayer.

The oil sprayer sprinkle the atomized oil to the products in the drum.By continuous rolling material, the drum will make oil and seasoner evenly adhere to the surface of products. To prevent feed leakage, the hoister is used wavy baffle belt.The oil sprayer can bear high temperature and pressure. Safe and durable. Mixing atomized oil and

The oil sprayer sprinkle the atomized oil to the products in the drum.By continuous rolling material, the drum will make oil and seasoner evenly adhere to the surface of products. To prevent feed leakage, the hoister is used wavy baffle belt.The oil sprayer can bear high temperature and pressure. Safe and durable. Mixing atomized oil and

products evenly in the flavoring drum.

Inverter to adjust the speed of spices. Easy to control.

Inverter to adjust the speed of spices. Easy to control.

Our Compnay

Jinan Zhuoheng Extrusion Machinery Co.,LTD established in 2008, has always been the professional manufacturer and the leader for

advanced and high efficient extrusion food machinery in this field all over the world.

advanced and high efficient extrusion food machinery in this field all over the world.

Our Service

1)Provide factory layout according to your factory size in advance;

2)Provide the basic formula;

3)Inspect the machine before leaving the factory;Oversea installation and commissioning equipment;

4)Technician will work with your workers together and teach your workers how to install machines,

how to operate machines, how to maintain machines during daily working;

5)Our engineers will teach your workers how to clean the extruder, how to change the screw,

how to change barrel etc, and provide technology support with you forever;

6)Provide English Version of Installation / Operation / Service / Maintenance Manual.

2)Provide the basic formula;

3)Inspect the machine before leaving the factory;Oversea installation and commissioning equipment;

4)Technician will work with your workers together and teach your workers how to install machines,

how to operate machines, how to maintain machines during daily working;

5)Our engineers will teach your workers how to clean the extruder, how to change the screw,

how to change barrel etc, and provide technology support with you forever;

6)Provide English Version of Installation / Operation / Service / Maintenance Manual.

Before -sale service

Our company could support the layout of machine lines according the size of your warehouse ,we also could give you our suggestion

Sale service

we would like to show the real details to our customer and try our best to make them understood our machine technology

After-sale service

Our team could support 24hourse service ,and we could arrange engineer come to fix the problem you have .

Packing&Delivery

• Inside package is plastic film, outside is wooden or plywood case(based on the customers'

need).

• Only plastic film nude packing with wooden pallet.

• We can supply fumigation package and certificate.

• Shipping, train, express or upon clients' demands.

need).

• Only plastic film nude packing with wooden pallet.

• We can supply fumigation package and certificate.

• Shipping, train, express or upon clients' demands.

Certifications

we could support SGS,CE,BV ,TUV certificate,also could support the files you required

FAQ

Q: Are you a trade company or a manufacturer?

A: we are a manufacturer, welcome to visit our factory and check the machines.

Q: How long is your delivery time?

A: Generally it is 5-10 days if the goods are in stock. or it is 20-35 days if the goods are not in stock, we could discuss before contract.

Q: Could you supply all the parameters about the machines?

A: Yes, we will supply all the parameters, price, layout drawing, factory design etc.

Q: What is your terms of payment ?

A: 30% T/T in advance , 70% balance before shippment after inspection.

Q: How about the after-service?

A: We will send 1-2 engineer to the buyer's factory for 7-15 days period installation and training to the operators.

Q:do you supply any formula to buyer?

A: yes, we supply formulas to buyer.

A: we are a manufacturer, welcome to visit our factory and check the machines.

Q: How long is your delivery time?

A: Generally it is 5-10 days if the goods are in stock. or it is 20-35 days if the goods are not in stock, we could discuss before contract.

Q: Could you supply all the parameters about the machines?

A: Yes, we will supply all the parameters, price, layout drawing, factory design etc.

Q: What is your terms of payment ?

A: 30% T/T in advance , 70% balance before shippment after inspection.

Q: How about the after-service?

A: We will send 1-2 engineer to the buyer's factory for 7-15 days period installation and training to the operators.

Q:do you supply any formula to buyer?

A: yes, we supply formulas to buyer.

Product Description

1). All fish food equipments are made of stainless steel.

2). The fish food whole line fully continuous and automatic.

3). Zhuoheng provide basic fish food formula according to your require.

4). The final fish food shapes and sizes can be various by changing the mould.

5). Supply different size mould free of charge.

6). Packing machine could be supplied to work with the fish feed production line (depending on your require)

2). The fish food whole line fully continuous and automatic.

3). Zhuoheng provide basic fish food formula according to your require.

4). The final fish food shapes and sizes can be various by changing the mould.

5). Supply different size mould free of charge.

6). Packing machine could be supplied to work with the fish feed production line (depending on your require)

Flow Chart

.

Grinding→mixing→extruding→drying→flavoring→cooling→packaging

Our engineer could design the layout drawing according to your dimension of the factory for the fish feed machines.

Our engineer could design the layout drawing according to your dimension of the factory for the fish feed machines.

Product Paramenters

|

Model

|

Installed Power(kw)

|

Power Consumption (kw)

|

Capacity(kg/h)

|

Dimension(m)

|

|

ZH65

|

110kw

|

70kw

|

120-150

|

25*3*3

|

|

ZH70

|

138kw

|

95kw

|

200-250

|

28*3*3

|

|

ZH85

|

240kw

|

160kw

|

500

|

30*3*3

|

|

ZH95

|

330kw

|

230kw

|

1000-1200

|

50*3*3

|

|

ZH115

|

400kw

|

280kw

|

2000

|

60*6*15

|

|

ZH135

|

500kw

|

350kw

|

3000

|

60*6*20

|

Raw Material

Rice flour, corn flour, wheat flour, low temperature soya flakes meal, rice bran , wheat bran, fish powder, bone powder etc.

Fish feed samples made by our machines

fish feed pellet /color customized/floating and sinking type/length customized

diameter from 0.2mm to 20mm

diameter from 0.2mm to 20mm

Equipment list in the fish feed production line:

mixer→screw conveyor→twin screw extruder→air conveyor→dryer→hoister→flavoring drum and oil sprayer→cooling machine→packing machine

Blender Mixer

Blend Mixer is a high standard two-way ribbon mixing machine. It includes material tank, screw mixing paddles and drive parts.

Screw

mixing paddles are the double deck structure or three-tier structure. Outside of the screw paddles collecting and mixing the raw

materials flour from two borders area to the center area. Meanwhile, the inside of the screw mixing paddles conveying and mixing the flour materials from center to the borders. Then it makes the convective mixing to ensure the flour materials mixing evenly with high efficiency.

Double screw extruder

Double Screw Extruder Unit is the high standard and professional extrusion machinery unit. It’s consist of bucket elevator, Storage Silo, material conveyor, conditioner, feeder,extruder, electric controller and operation platform. The extruder includes drive system, extrusion system, cutting system,heating system, lubricating system and extraction steam system. Conditioner is designed as the advanced technology biaxial differential modulator. It can higher the materials temperature,make flour materials softer, lower the materials’ friction . Thus reducing the extrusion power consumption, increasing the

output, improving the stability of the extruder operation, prolonging life of t the whole extruder unit.

output, improving the stability of the extruder operation, prolonging life of t the whole extruder unit.

Hot Air criculation Baking oven

Heat With Infrared Ray Heating Tube, Raise And Lower Down Temperature Quickly, Small Heat Inertia And High Heat Efficiency.

Adjustable Transit Speed Of Net Belt With Accurate Temperature Control Device. Sliding Board Bottom Of Dryer For Easy Cleaning. Hot Wind Cycle Device Makes Heating Energy Equally In The Dryer

Double-Roller Chain And Chain Drive Make Stable And Smooth Running.

Adjustable Transit Speed Of Net Belt With Accurate Temperature Control Device. Sliding Board Bottom Of Dryer For Easy Cleaning. Hot Wind Cycle Device Makes Heating Energy Equally In The Dryer

Double-Roller Chain And Chain Drive Make Stable And Smooth Running.

Single drum flavoring line

It’s consist of hoistor, drum machine, flavoring machine and oil sprayer.

The oil sprayer sprinkle the atomized oil to the products in the drum.By continuous rolling material, the drum will make oil and seasoner evenly adhere to the surface of products. To prevent feed leakage, the hoister is used wavy baffle belt.The oil sprayer can bear high temperature and pressure. Safe and durable. Mixing atomized oil and

The oil sprayer sprinkle the atomized oil to the products in the drum.By continuous rolling material, the drum will make oil and seasoner evenly adhere to the surface of products. To prevent feed leakage, the hoister is used wavy baffle belt.The oil sprayer can bear high temperature and pressure. Safe and durable. Mixing atomized oil and

products evenly in the flavoring drum.

Inverter to adjust the speed of spices. Easy to control.

Inverter to adjust the speed of spices. Easy to control.

Our Compnay

Jinan Zhuoheng Extrusion Machinery Co.,LTD established in 2008, has always been the professional manufacturer and the leader for

advanced and high efficient extrusion food machinery in this field all over the world.

advanced and high efficient extrusion food machinery in this field all over the world.

Our Service

1)Provide factory layout according to your factory size in advance;

2)Provide the basic formula;

3)Inspect the machine before leaving the factory;Oversea installation and commissioning equipment;

4)Technician will work with your workers together and teach your workers how to install machines,

how to operate machines, how to maintain machines during daily working;

5)Our engineers will teach your workers how to clean the extruder, how to change the screw,

how to change barrel etc, and provide technology support with you forever;

6)Provide English Version of Installation / Operation / Service / Maintenance Manual.

2)Provide the basic formula;

3)Inspect the machine before leaving the factory;Oversea installation and commissioning equipment;

4)Technician will work with your workers together and teach your workers how to install machines,

how to operate machines, how to maintain machines during daily working;

5)Our engineers will teach your workers how to clean the extruder, how to change the screw,

how to change barrel etc, and provide technology support with you forever;

6)Provide English Version of Installation / Operation / Service / Maintenance Manual.

Before -sale service

Our company could support the layout of machine lines according the size of your warehouse ,we also could give you our suggestion

Sale service

we would like to show the real details to our customer and try our best to make them understood our machine technology

After-sale service

Our team could support 24hourse service ,and we could arrange engineer come to fix the problem you have .

Packing&Delivery

• Inside package is plastic film, outside is wooden or plywood case(based on the customers'

need).

• Only plastic film nude packing with wooden pallet.

• We can supply fumigation package and certificate.

• Shipping, train, express or upon clients' demands.

need).

• Only plastic film nude packing with wooden pallet.

• We can supply fumigation package and certificate.

• Shipping, train, express or upon clients' demands.

Certifications

we could support SGS,CE,BV ,TUV certificate,also could support the files you required

FAQ

Q: Are you a trade company or a manufacturer?

A: we are a manufacturer, welcome to visit our factory and check the machines.

Q: How long is your delivery time?

A: Generally it is 5-10 days if the goods are in stock. or it is 20-35 days if the goods are not in stock, we could discuss before contract.

Q: Could you supply all the parameters about the machines?

A: Yes, we will supply all the parameters, price, layout drawing, factory design etc.

Q: What is your terms of payment ?

A: 30% T/T in advance , 70% balance before shippment after inspection.

Q: How about the after-service?

A: We will send 1-2 engineer to the buyer's factory for 7-15 days period installation and training to the operators.

Q:do you supply any formula to buyer?

A: yes, we supply formulas to buyer.

A: we are a manufacturer, welcome to visit our factory and check the machines.

Q: How long is your delivery time?

A: Generally it is 5-10 days if the goods are in stock. or it is 20-35 days if the goods are not in stock, we could discuss before contract.

Q: Could you supply all the parameters about the machines?

A: Yes, we will supply all the parameters, price, layout drawing, factory design etc.

Q: What is your terms of payment ?

A: 30% T/T in advance , 70% balance before shippment after inspection.

Q: How about the after-service?

A: We will send 1-2 engineer to the buyer's factory for 7-15 days period installation and training to the operators.

Q:do you supply any formula to buyer?

A: yes, we supply formulas to buyer.

Hot Searches