- Product Details

- {{item.text}}

Quick Details

-

Bending tensile stress (MPa):

-

76

-

Flammability class:

-

HB

-

Melting point(℃):

-

220

-

Diameter(mm):

-

5~50

-

Color in Stock:

-

White, Blue or Customized

-

Temperature:

-

-269 ~ + 85 ℃

-

Application:

-

Buffer pads, gears, high impact wear etc.

-

Melting Point:

-

220℃

Quick Details

-

Place of Origin:

-

Jiangsu, China

-

Brand Name:

-

YINHE

-

Density (g/cm3):

-

1.14

-

Bending tensile stress (MPa):

-

76

-

Flammability class:

-

HB

-

Melting point(℃):

-

220

-

Diameter(mm):

-

5~50

-

Color in Stock:

-

White, Blue or Customized

-

Temperature:

-

-269 ~ + 85 ℃

-

Application:

-

Buffer pads, gears, high impact wear etc.

-

Melting Point:

-

220℃

Quick Details

Place of Origin: Jiangsu, China (Mainland)

Brand Name: Yinhe

Max Height: 2m

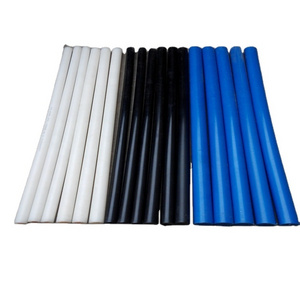

Color: white, black, blue, nature

Temperature: -269 ~ + 85 ℃

Application: Buffer pads, gears, high impact wear etc.

Rockwell Hardness: M85

Type: Cast, Extruded

Melting Point: 220℃

Density: 1.16 cm³

Tensile strength: 85 MPa

Description

China MC PA6 PA66 Nylon Rod made by Yinhe Plastic

1. What is Polyamide (PA) or Nylon?

- Polyamide (PA) is a kind of thermoplastic engineering plastic material, also can be called Nylon. It is the most important engineering plastic material in the world, and widely used in cars, machinery, electronics, communications-equipment, architecture.

- This material is a kind of transparent or semitransparent white crystalline polymer, and has a large range of usage temperature. There are PA6, PA66 for this material, and PA66 has better properties in mechanical strength, stiffness, heat and abrasion resistance, size stability, but impact strength is not very good.

- There is another material in Polyamide(PA) called MC Nylon, have much better properties in mechanical strength, stiffness, impact strength, it is suitable to make large product which can be extruded.

2. Features

PA6:

- Easy to dye, more readily fades;

- Higher impact resistance,

- More rapid moisture absorption,

- Greater elasticity and elastic recovery.

PA66:

- Pleats and creases can be heat-set at higher temperatures

- More compact molecular structure

- Better weathering properties; better sunlight resistance

- Higher melting point (256 °C/492.8 °F)

- Excellent abrasion resistance

MC Nylon:

- Better properties in mechanical strength, stiffness, impact strength

- Suitable to make large product which can be extruded.

3. Applications

- Transmission parts

- Home appliance parts

- Automotive parts

- Chemical equipment

- Electrical insulation parts

4. Specification

|

Item |

Color in Stock |

Diameter(mm) |

Length(mm) |

|

Nylon Rod |

White, Blue or Customized |

5~50 |

1000 |

|

2000 |

|||

|

or customized |

5. Technical Parameters

|

Item |

PA6 |

PA66 |

MC Nylon |

|

Density (g/cm³) |

1.14 |

1.14 |

1.15 |

|

Melting point(℃) |

220 |

225 |

220 |

|

Flammability class |

HB |

HB |

HB |

|

Bending tensile stress (MPa) |

76 |

90 |

85 |

|

Packaging |

1. Wooden case. |

|

|

2. According to customer’s requirement |

|

Delivery |

1. Stock size 1-3 working days. |

|

|

2. Custom size 10-15 working days. |