- Product Details

- {{item.text}}

Quick Details

-

Application:

-

Textile Coating

-

Mixing ratio:

-

1:1

-

Hardness:

-

20 shore A

-

Color:

-

Transparent

-

HS code:

-

391000000

-

Shelf life:

-

12 months

-

MOQ:

-

100kg

-

Packaging:

-

5kg/25kg/200kg

-

Working time:

-

30-50 minutes

-

Setting time:

-

3-5 hours

Quick Details

-

Place of Origin:

-

GUA

-

Brand Name:

-

INIBABA

-

Model Number:

-

INI-4120

-

Application:

-

Textile Coating

-

Mixing ratio:

-

1:1

-

Hardness:

-

20 shore A

-

Color:

-

Transparent

-

HS code:

-

391000000

-

Shelf life:

-

12 months

-

MOQ:

-

100kg

-

Packaging:

-

5kg/25kg/200kg

-

Working time:

-

30-50 minutes

-

Setting time:

-

3-5 hours

Screen Printing & Heat Transfer

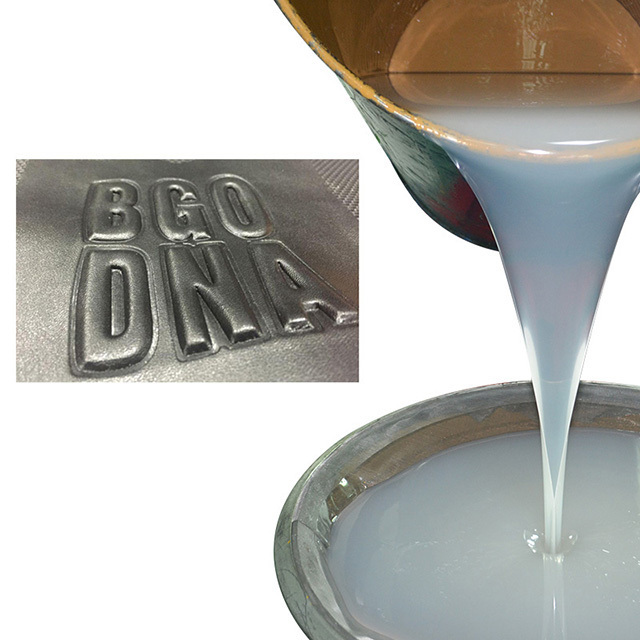

Printing & Embossing Silicone

INI-4120

Description

This silicone rubber can be firmly adhered to the surface of textiles by screen printing. Widely used in textile printing of clothing, socks, hats, gloves, etc. It ’ s platinum cure liquid silicone rubber, FDA food grade, non-toxic, odorless.

It can be operated more easily without additives , suitable for both manual and mechanized.

Application

This silicone rubber is widely used in garment factories; garment accessories factories; printing and embossing factories; hat factories; shoes factories; socks factories, bags and handbags factories; craft gifts factories; embroidery factories; marking and ribbon factories, etc.

Features & Advantages

-

Environmental protection/non-toxicity , FDA food grade silicone

-

High viscosity, not easy to penetrate textile

-

Can set color (multi-layer color), do not fall off when set color, pattern is not single, can form different patterns, silicone printing trend leads the fashion field.

-

Various effects can be printed (bright or matte, round or right-angled effect, thick or thin, large or small patterns ), strong stereoscopic effect, soft handle and strong adhesion

-

High wear resistance, brightness and washability

-

C an firmly adhere to the surface of textiles, non-woven fabrics, dermis, imitation leather and other materials.

-

The effect of wool pressing is good.

-

Solve the problem of firmness of leather and waterproof fabric effectively

-

Printing gloves, clothing, paper, sports goods, etc., cold and heat resistance, skid resistance, silk-printed patterns have a strong three-dimensional feel, and fee l soft, and complement each other with textiles or leather goods; silk-printed patterns also have excellent peeling strength, wear resistance, brightness; it also has water-proof, skid-proof, breathable, high resistance, low temperature. And good leveling.

-

Super elasticity, in the normal range of elasticity of the fabric does not fall off, cracking. P rinting patterns do not decolor, do not re-dye (not sublimate).

-

Good air permeability, outside water, oil and other pollutants can not enter, while the inside of the hot air can be permeable.

Operation instructions

-

Mix part A and pars B evenly with 1:1 mixing ratio exactly by electronic weight.

-

Vacuum pumping

Notes: 1) This step is not have to have, but it is best if there is one. It will discharge all air in the mixture successfully, so as to ensure that there

will be no bubbles in the finished product.

2) This step is less than 10 minutes. Otherwise, it

Will cause cross-linking reaction, and no more

further steps will be available.

3.1 Screen printing to get a flat pattern.

3.2 Embossing. Pour the mixed materials into the mould and molded into a three-dimensional pattern on the surface of the textile.

4. Vulcanization molding

According to the actual needs, heat and dry the printed products.

Typical properties INI-4120

|

Properties I ndex |

Test Report |

|

|

Before Curing |

Appearance |

Transparent fluid |

|

Viscosity(cps) |

80000 ± 50000 (Adjustable) |

|

|

O perati ng |

Mixing Ratio (By weight) |

1 : 1 or 10 : 1 |

|

Operating Time( hours, 2 3 ℃) |

1 ~ 48 (Adjustable) |

|

|

Curing time ( seconds, 125℃ ) |

10~150 (Adjustable) |

|

|

After Curing |

Hardness (shore A) |

20 ± 2 |

|

Tear strength (kN/m) |

18 ± 4 |

|

|

Tensile strength (Mpa) |

5 ± 1 |

|

|

Elongation (%) |

470~600 |

|

|

Density (g/cm) |

1. 02 |

|

Handing and Storage

-

Precautions for safe handling:

Protective measures: Training should be provided to anyone working with or near this material. Training should cover potential health effects and proper handling techniques. Avoid contact with eyes, skin and clothing. Avoid ingestion and inhalation.

Measure to protect the environment: Do not allow this products to be released to the environment

without proper treatment.

Advice on general occupational hygiene: Eating, drinking and smoking should be prohibited in

areas where this material is handled, stored and processed.

-

Conditions for safe storage, including any incompatibilities:

Technical measures and storage conditions: Store

in a cool, dry, well-ventilated area away from

incompatible substances, feeds tuffs, beverages and foods. Treat carefully, avoid physical damage to containers. The storage area should be equipped with the corresponding species and quantity of emergency equipment, spills emergency treatment equipment and appropriate storage material.

Requirements for storage rooms and vessels: Keep container tightly sealed .

P ackage

5KG, 20KG, 25KG and 200KG per drum.

(There are metal drum and plastic drum for your choice for 5KG and 20KG)

S helf life

Twelve(12) months when stored under dry and cool place by original package under 25℃.

Advantages of Hong Ye Silicone

-

21 years rtv2 silicone factory

-

Return and exchange are accepted while quality problems occurred

-

Exported since 2006

-

Exports to 138 countries

-

15 years on alibaba.com, 13 years on made-in-china.com, a trustworthy company

-

12 professional experts of R&D, QC staffs

-

6000 square meter factory

-

Manufacturer direct deal, support guarantee

-

Free training of silicone technique

-

Free silicone samples

Our Company:

INIBABA is a silicone rubber manufacturer in China that has ability to manufacture electric power water proof polymer, rtv2 silicone rubber, liquid silicone rubber, silicone potting, silicone gel, sticky silicone, silicone glue, silicone elastomer, platinum cured silicone rubber , tin cured silicone rubber.

According to the wide application, we can provide electronic potting silicone, mold making silicone, food grade silicone, pad printing silicone, coating silicone for textile and fiberglass, special effects silicone, silicone for military and high-tech, medical silicone, silicone for making sex toys, shoe insoles, printing roller, silicone badge, silicone toys, tattoo practices skins, medical educational supplies, suture pad, scar treatment patch and so on.

With advanced the technology of silicone production and high tech equipment, the silicone rubber provided by INIBABA has excellent quality without shrinkage problem, oily problem and implete curing problem. Through the control of multiple processes, INIBABA silicone gel is more delicate, so it has higher tear resistance and tensile performance, and the molds and products are more flexible and durable.

WHY CHOOSE INIBABA:

1. As a manufacturer, after-sales service and technical support are guaranteed, once you meet problem during using silicone, INIBABA will provide effective solution in the first time.

2. One to one service, guaranteed to teach you how to use silicone. If you are a beginner in silicone application, INIBABA team will be at your service.

3. The quality of silicone products is leading the world level with advanced technology and 50 production processes for quality protection by supervised by professional doctoral team.

Fast delivery by 1-3 days, with many high-end equipment, the production capacity is several times than most of manufactures in the same industry.

Package details:

5kg/20kg/25kg/200kg

Shelf life:

Twelve(12) months when stored under dry and cool place by original package under 25℃

This kind of product is non-dangerous product, which could be transported as general chemicals.

Payment Terms:

1. We accept T/T,L/C for big amount.

2. For small amount, you can pay us by Paypal.

For trial order, please contact Mr Joe whatsapp/cellphone: +86 17384217441