- Product Details

- {{item.text}}

Quick Details

-

Screw Speed (rpm):

-

600 rpm

-

Place of Origin:

-

Jiangsu, China

-

Brand Name:

-

Haisi

-

Voltage:

-

220V/380V

-

Dimension(L*W*H):

-

CAPACITY

-

Power (kW):

-

132

-

Weight:

-

3000 KG

-

After-sales Service Provided:

-

Engineers available to service machinery overseas

-

Output:

-

Around 500kg/h

-

Plastic Pellet:

-

3*3mm

-

Cutter tooth number:

-

32 strand

-

Motor:

-

1.5kw /3kw

-

Usage:

-

Cut plastics filling strand

-

Cutter Dimension:

-

65mm

-

Other name:

-

bio plastic pelletizing line

-

Output (kg/h):

-

350 - 550

-

Certification:

-

ISO9001

Quick Details

-

Screw Design:

-

Double-screw

-

Screw L/D Ratio:

-

32-64

-

Screw diameter (mm):

-

62.4 mm

-

Screw Speed (rpm):

-

600 rpm

-

Place of Origin:

-

Jiangsu, China

-

Brand Name:

-

Haisi

-

Voltage:

-

220V/380V

-

Dimension(L*W*H):

-

CAPACITY

-

Power (kW):

-

132

-

Weight:

-

3000 KG

-

After-sales Service Provided:

-

Engineers available to service machinery overseas

-

Output:

-

Around 500kg/h

-

Plastic Pellet:

-

3*3mm

-

Cutter tooth number:

-

32 strand

-

Motor:

-

1.5kw /3kw

-

Usage:

-

Cut plastics filling strand

-

Cutter Dimension:

-

65mm

-

Other name:

-

bio plastic pelletizing line

-

Output (kg/h):

-

350 - 550

-

Certification:

-

ISO9001

Bio Plastic Pellets Machine / Co-rotating Plastic Granules Twin Screw Extruder

1.Technical Data

| Mode |

Diameter(mm) |

L/D |

speed(r/min) |

Motor power(kw) |

Torque(N.m) |

Capacity(kg/h) |

| TSE-20 | 22 | 32-44 | 600 | 5.5 | 43 | 0.5-10 |

| TSE-30B | 31 | 32-48 | 600 | 15 | 119 | 5-40 |

| TSH-35B | 35.6 | 32-52 | 600-800 | 15-22 | 119 | 30-70 |

| TSE-40B | 41 | 32-52 | 600 | 45-55 | 437 | 90-150 |

| TSH-40B | 41 | 32-52 | 600 | 45-55 | 437 | 150-220 |

| TSE-5 0 B | 50.5 | 32-52 | 500 | 45-55 | 430 | 180-270 |

| TSH-52B | 51.5 | 32-60 | 600 | 90-132 | 682 | 270-400 |

| TSE-65B | 62.4 | 32-64 | 600 | 90 | 716 | 250-360 |

| TSH-65B | 62.4 | 32-64 | 600-800 | 110-160 | 875 | 350-500 |

| TSE-75B | 71 | 32-64 | 600 | 132 | 1050 | 350-500 |

| TS H -75 B | 71 | 32-64 | 600-800 | 200-250 | 1365 | 600-800 |

| TSE-95B | 93 | 32-64 | 600 | 315 | 2560 | 800-1200 |

| TSH-95B | 93 | 32-64 | 600-800 | 400-450 | 2506 | 1200-1600 |

| TSE-135 | 133 | 32-64 | 500 | 550 | 7162 | 1500-2250 |

*Our plastic extrusion machine use innovated design of heater tightened style, it insures high efficiency of heat transfer and high longevity of heater.

*Our plastic extrusion machine has Various modes of pelletizing, such as water-cooling strand, air-cooling pelletizing, water-ring pelletizing, under water pelletizing etc.

*The screw is made of high tool steel 38 CrMoALA or W6Mo5Cr4V2 by special heat-treatment, which is possessed with high corrosion-resistant and high functions

*The screw configuration, barrel setup, L/D or mode of feeding and venting, screen changing, way of granulating, and the control mode can be optimally adjusted according to different materials properties and requirements in consideration of the versatility in each general applications.

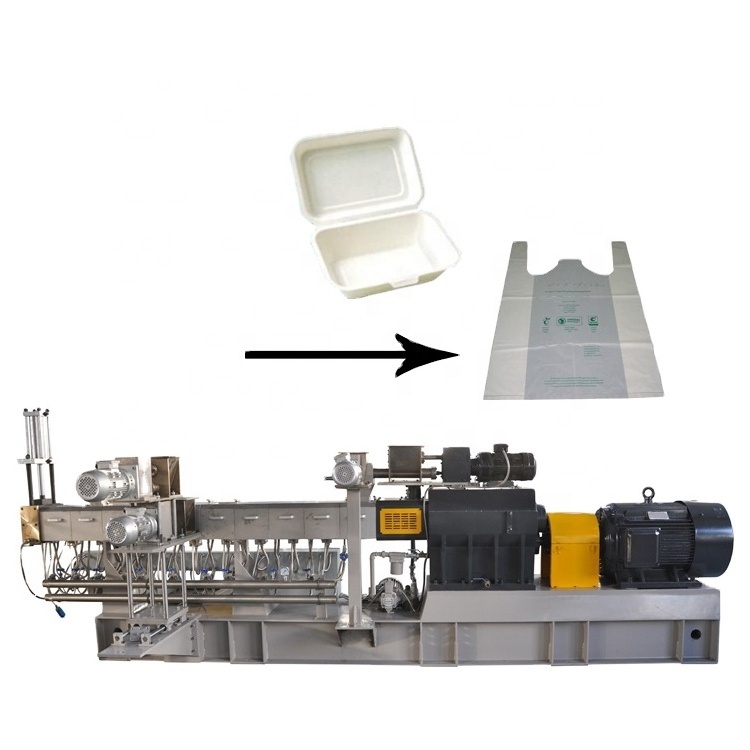

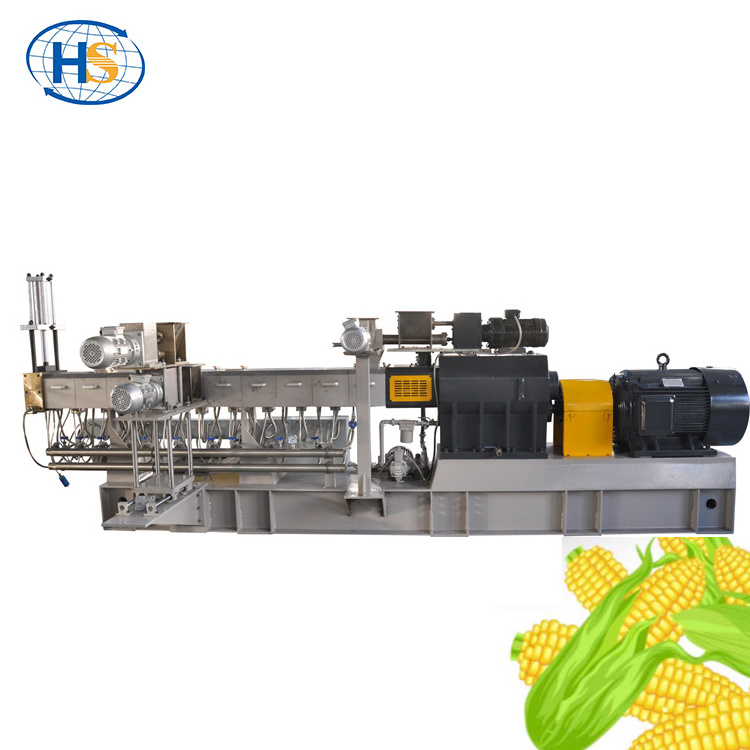

Starch and pp pe ps are degradable after mixing,and it is mainly used as agricultural film and horticultural material in agriculture; the application in catering industry is mainly used as fast food boxes, disposable cups, plates, and knives and forks; the packaging materials are mainly the packaging of daily items, including various shopping bags, Bags, garbage bags, food bags, etc.

3.Functions and Features :

1.Integrate feeding material, weighting, bag clipping, bag packing, conveying and sealing.

2.Automatic pack reduction and automatic calibration during the weighing each time.

3.Have functions such as long-range controlling and trouble diagnosing, repairing , ultra difference alarms and so on.

4.Adopt gravity feeding method internally inside the package to ensure high metering accuracy and fast packing speed.

5.24-bit fast A/D converter and intelligent digital filtering technology, strong anti-interference, fast and stable.

6.Weight meter adopts aluminum alloy enclosure, with high anti-interference performance and simple operation.

7.Double CPU construction, with power down data protection inside the unit.

8.Full enclosure design, negative pressure operation inside the unit, without dust escape, with clean environment.

|

Process |

Representative materials |

|

Mixing nature-changing |

PE/ PP/ PS+SBS; PA+EPDM; PP+NBR; EVA +Silicon rubber, etc. |

|

PE/ PA/ PC/ CPE+ABS(alloy); PBT+PET; PP+ PE, etc. |

|

|

Filling nature-changing |

PE/ PP/ EVA, ect. + Calcium carbonate/ talcum powder/ titanic powder; ABS/PC/PS, etc. +aluminum hydroxide/ magnesium hydroxide/ antimony oxide. |

|

PP/ PA/ ABS+ ferrous powder/ sulphuric powder/ ceramic powder |

|

|

Functional machine pellets |

PP/ PA/ ABS/ PBT, etc+ anti-burning agent and other auxiliary agents: combustion-supporting machine pellets |

|

PE/ PP/ PS, etc+ starch: de-composing machine pellets |

|

|

PE+ fog-preventing dipper, stabilizer: dual-prevention machine pellets |

|

|

PE/ EVA/ ABS, etc.+ carbon black; black machine pellets |

|

|

Colored machine pellets |

PE/ PP/ ABS/ AS/ PA/ EVA/ PET +pigment and auxiliary |

|

Intensified glass fibres and carbon fibres |

PP/ PBT/ ABS/ AS/ PA/ PC/ POM/ PPS/ PET, etc. + long fires/ small fibres/ carbon fibres/ crystals and so on, etc. |

|

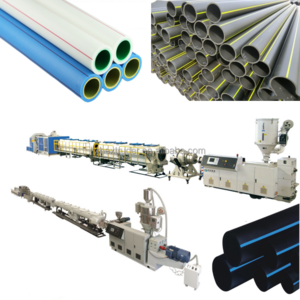

Various cables |

HDPE/ LDPE/ LLDPE/ MDPE/ EVA/ PVC/ PP, etc. insulating cables/ coatings; PE peroxide silicon alkyl crossing cables; radialization crossing cables. |

|

Special materials |

EVA heat-melting glue, polyurethane, fluorin rubber, fluorine plastics , PP cigarette filtering material and TPR sole material |

|

Reaction extruding |

Polyamide condensate, polyamide melting polymerization, polyamide polyethene-adding, polycarbonate condensate, etc. |

|

Exhausting and volatilization |

Polystyrene oxide, high-absorbing resin, chlorine sulphur piolyethylene |

|

Powder paint |

Polyester, ring oxide, lactide, polyurethane, acrylate |

1. Q: How about Haisi?

R: Nanjing Haisi Extrusion Extrusion Equipment Co., Ltd. is a High-Tech company. Our firm is composed of a strong team which has substantial experience in R&D, manufacture, technique and service, and has specialized in extruder industry for ten years, leading screw barrel manufacturer in China.

2. Q: What's Haisi capacity?

R: Our company is in strict accordance with CE and ISO9001 quality certification system. there are over 200 models of extruders and spare parts.

3. Q: What's the delivery time?

R: For regular size, we have finished stock and semi-finished stock, 2 weeks max are enough for customized, normally 3~4 weeks.

4. Q: Where is Haisi factory and how to reach there?

R: At Lishui, Nanjing, Jiangsu Province. If you want to visit us, we can pick you up in the airpor or train station.

5. Q: How to contact with us?

R: Plz reply to me directly if you have any question.