- Product Details

- {{item.text}}

Quick Details

-

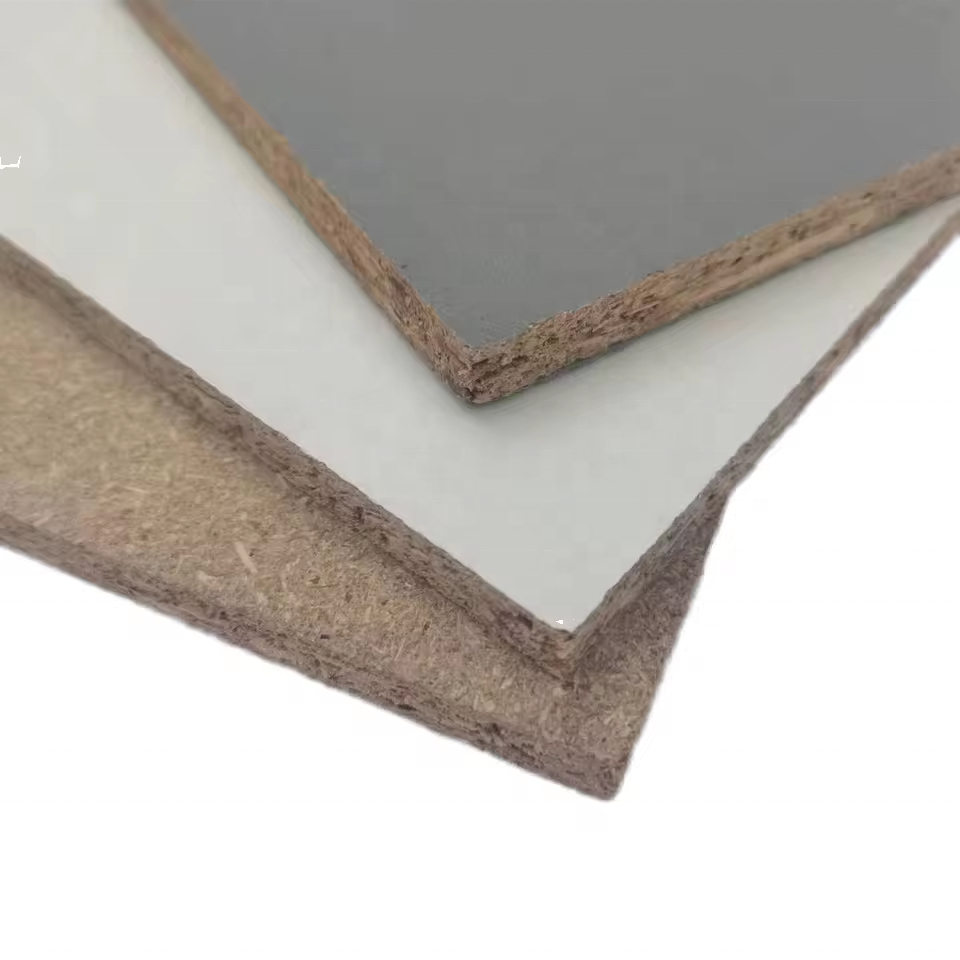

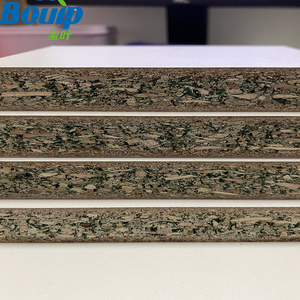

Slab Structure:

-

3-Layer Structure Boards

-

Place of Origin:

-

Guangdong, China

-

Brand Name:

-

XINQIU

-

Model Number:

-

XQ001

-

Product name:

-

Melamine Particle Board

-

Size:

-

1220x2440mm/1220x2745mm/1530x2440mm/1530x2440mm/2070x2800mm

-

Thickness:

-

9~25mm

-

Glue:

-

E0/E1/E2/MELAMINE/MR/WBP

-

Certificate:

-

CABR CE FSC ISO9001 ISO14001

-

Material:

-

Pine Wood

-

Density:

-

680-700kg/m3

-

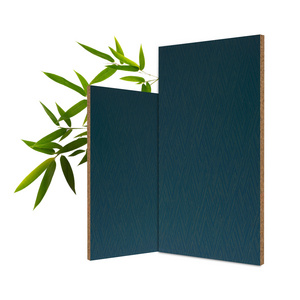

Color:

-

Natural

-

Keywords:

-

Wood Particleboard

-

Advantage:

-

Moisture Proof

Quick Details

-

Project Solution Capability:

-

graphic design, total solution for projects

-

Application:

-

Office Building

-

Grade:

-

Excellent

-

Slab Structure:

-

3-Layer Structure Boards

-

Place of Origin:

-

Guangdong, China

-

Brand Name:

-

XINQIU

-

Model Number:

-

XQ001

-

Product name:

-

Melamine Particle Board

-

Size:

-

1220x2440mm/1220x2745mm/1530x2440mm/1530x2440mm/2070x2800mm

-

Thickness:

-

9~25mm

-

Glue:

-

E0/E1/E2/MELAMINE/MR/WBP

-

Certificate:

-

CABR CE FSC ISO9001 ISO14001

-

Material:

-

Pine Wood

-

Density:

-

680-700kg/m3

-

Color:

-

Natural

-

Keywords:

-

Wood Particleboard

-

Advantage:

-

Moisture Proof

Specification

|

Product name

|

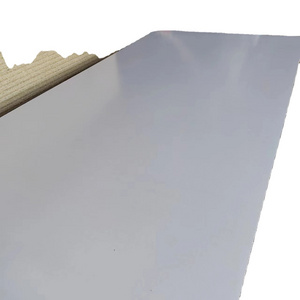

Melamine Particle Board

|

|

Size

|

1220x2440mm/1220x2745mm/1530x2440mm/2070x2800mm

|

|

Thickness

|

9mm/12mm/15mm/16mm/18mm/25mm

|

|

Glue

|

E0/E1/E2/MELAMINE/MR/WBP

|

|

Certificate

|

CABR CE FSC ISO9001 ISO14001

|

|

Material

|

Pine Wood

|

|

Density

|

680-700kg/m3

|

|

Solid Wood

|

Solid Wood Finish

|

|

Advantage

|

Moisture Proof

|

|

Packing

|

Standard Pallet Packing

|

|

MOQ

|

1x20GP

|

|

Delivery Time

|

Within 7 Days

|

Packing & Delivery

technological requirements ONE

Appropriate moisture content. When the surface moisture content is between 18-20%, it is beneficial to improve the bending strength, tensile strength, and surface smoothness, reducing the possibility of bubbling and layering during unloading of the slab. The moisture content of the core layer should be appropriately lower than that of the surface layer to maintain appropriate planar tensile strength.

Has good sound absorption and insulation performance; Particle board insulation and sound absorption;

technological requirements TWO

Appropriate hot pressing pressure. Pressure can affect the contact area between particles, the deviation in board thickness, and the degree of adhesive transfer between particles. According to the different density requirements of the product, the hot pressing pressure is generally 1.2-1.4 megapascals.

The surface of the particle board is flat and can be used for various veneers。

In the production process of particleboard, the amount of adhesive used is relatively small, and the environmental protection coefficient is relatively high

technological requirements Three

Appropriate temperature. Excessive temperature not only causes the decomposition of urea formaldehyde resin, but also causes local early solidification of the slab during heating, resulting in waste products.

Appropriate pressurization time. If the time is too short, the middle layer resin cannot be fully cured, and the elastic recovery of the finished product in the thickness direction increases, resulting in a significant decrease in planar tensile strength.

Hot Searches