- Product Details

- {{item.text}}

Quick Details

-

Weight:

-

50000 KG

-

Place of Origin:

-

Shanghai, China

-

Voltage:

-

220V 380V

-

Key Machines:

-

extraction

-

Product Type:

-

gelatin

-

Name:

-

gelatin production plant

-

Raw material:

-

Sainless Steel

-

Input material:

-

Collagen of bones and skin of pigs, cattle, sheep and other animals

-

Output Product:

-

gelatin

-

Capacity:

-

1T-5T per hour

-

Processing:

-

Automatic

-

Applicable Industries:

-

Manufacturing Plant

-

After Warranty Service:

-

Field maintenance and repair service

-

Warranty of core components:

-

2 years

Quick Details

-

Machinery Capacity:

-

customized

-

Brand Name:

-

Genyond

-

Dimension(L*W*H):

-

Customized

-

Weight:

-

50000 KG

-

Place of Origin:

-

Shanghai, China

-

Voltage:

-

220V 380V

-

Key Machines:

-

extraction

-

Product Type:

-

gelatin

-

Name:

-

gelatin production plant

-

Raw material:

-

Sainless Steel

-

Input material:

-

Collagen of bones and skin of pigs, cattle, sheep and other animals

-

Output Product:

-

gelatin

-

Capacity:

-

1T-5T per hour

-

Processing:

-

Automatic

-

Applicable Industries:

-

Manufacturing Plant

-

After Warranty Service:

-

Field maintenance and repair service

-

Warranty of core components:

-

2 years

Gelatin Production Line

Introduction:

Edible gelatin uses collagen from bones and skin of animals such as pigs, cattle, and sheep. Processed by denaturing degradation. Containing more than 8 kinds of L-type amino acids, it is a pure protein. Free of fat and cholesterol. Gelatin food made of wool, easily absorbed by the human body. It has a certain effect on certain diseases, especially children with ideal nutritional value.

The raw materials for edible gelatin production are different from industrial gelatin. They need to be processed with fresh, strictly quarantined pigs, cattle and other animal bones or raw hides without any chemical treatment, and dried and pulverized in a completely closed assembly line.

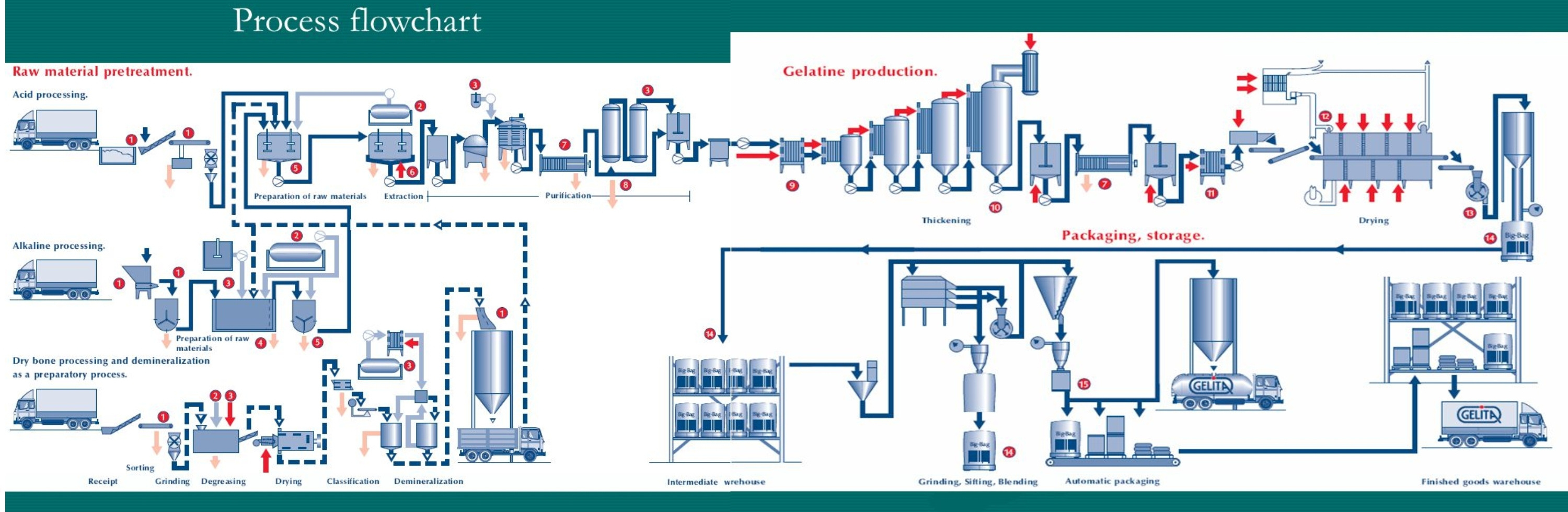

Processing flow chart:

Animal bones and skins are fully impregnated with a lime emulsion, neutralized with hydrochloric acid, washed with water, boiled at 60 to 70 ° C, and then subjected to antiseptic, bleaching, freezing, shaving, and drying.

The advanced glue extraction system is an advanced glue extraction equipment. The collagen extraction equipment combines advanced automation control, human-machine interface, advanced pumps, valves, and sanitary pipelines to implement waiting glue extraction, external circulation glue extraction, and continuous glue extraction. Integration.

Pretreatment → Washed → boiled glue → filtered → concentrated → antiseptic → frozen cut glue → dried → washed → finished product

Specification:

|

Model |

Output(bph) |

Steam consumption(KG) |

Power(KW) |

Area required(m 3) |

|

GY-2000 |

20 |

1500 |

300 |

800 |

|

GY -5000 |

50 |

3000 |

350 |

1500 |

|

GY-10000 |

100 |

5000 |

450 |

2500 |

Pictures:

GENYOND MACHINERY INDUSTRIAL GROUP

It has 6 factories in China for food machine and packing machine.

Shanghai Genyond Technology Co Ltd; Zhangjiagang Genyond Machinery Co Ltd

Shanghai Jou Yu industrial Co Ltd; Shanghai Keyfood Machinery Co Ltd

Sino topone machinery; Nantong Yihai Machinery; Kunshan Kpack Machinery

Our products have been exported to more than 160 countries with Annual sales reaching 80 millions in 2022 and it raises by yearly average 10% above.

Genyond machine has more than 100 engineers for the installation of oversea projects.

You just need to give us your idea on final product to be made, processing capacity, way of packing, we will make the proposals for your checking. You can also give us your budget, we can also design a line to meet your budget accordingly.

A satisfying project will be given; A long-term cooperation will come.

Album Chen

Mob /Wechat/Whatsapp : +86 18 116192278

Add : No. 1328, Hengnan Road, Pujiang Town, Minhang District,Shanghai

Web: www.buychinamachine.com

SHANGHAI GENYOND TECHNOLOGY CO.,LTD.

GENYOND MACHINERY INDUSTRIAL GROUP