- Product Details

- {{item.text}}

Quick Details

-

EINECS No.:

-

618-464-3

-

Place of Origin:

-

Hebei, China

-

Main Raw Material:

-

urea,formaldehyde

-

Brand Name:

-

TS

-

Model Number:

-

UF-1

-

Type:

-

TSGY

-

HS code:

-

3909 1000

Quick Details

-

CAS No.:

-

9011-05-6

-

Other Names:

-

ureaformaldehyde resin

-

MF:

-

C2H4N6O2

-

EINECS No.:

-

618-464-3

-

Place of Origin:

-

Hebei, China

-

Main Raw Material:

-

urea,formaldehyde

-

Brand Name:

-

TS

-

Model Number:

-

UF-1

-

Type:

-

TSGY

-

HS code:

-

3909 1000

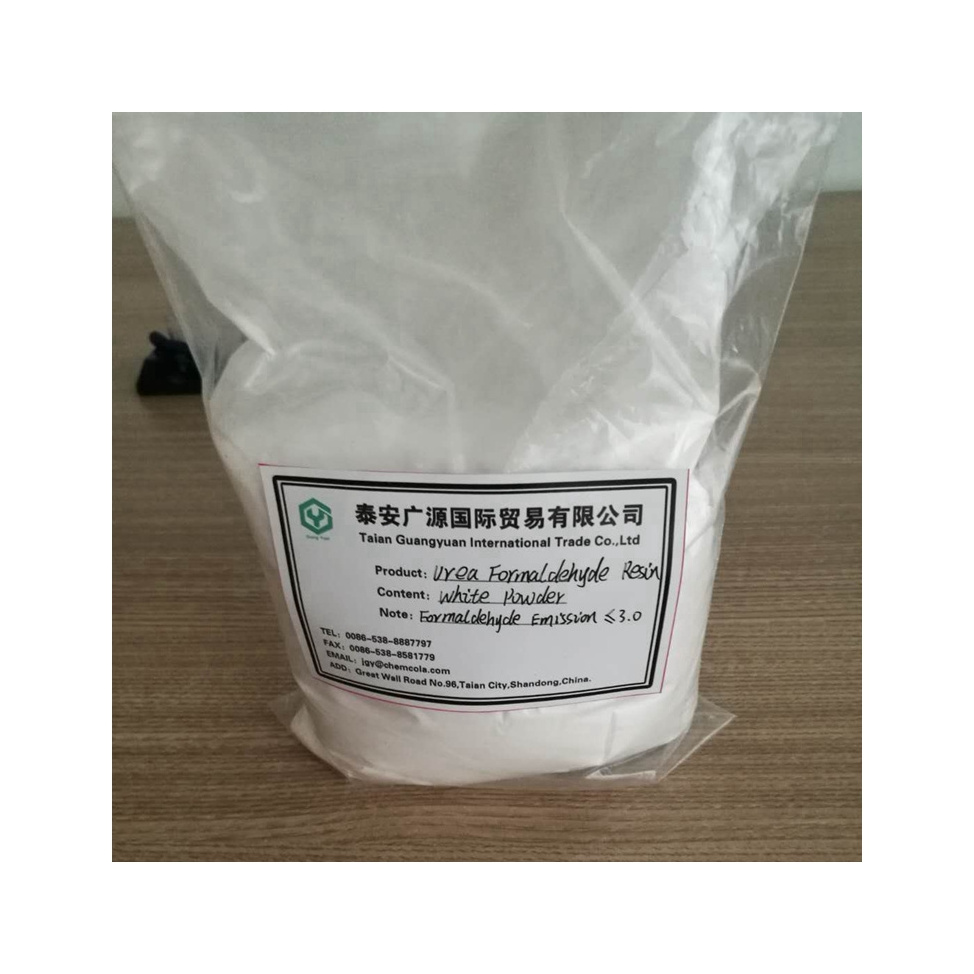

Plywood use urea-formaldehyde glue manufacturer

Main Technical Specification:

|

Item |

Specification |

Result |

|

Appearance |

White powder |

Meet the requirement |

|

Viscosity (50% solution) |

≥20mPa.s |

86mPa.s |

|

Content |

≥97% |

98% |

|

Volatile substance |

<2 |

1.9 |

|

Moisture content |

≤2 |

1.8 |

|

PH |

7.0-9.5 |

8.5 |

|

Specific gravity at 25 ℃ |

1.220g/cm 3 |

1.2 |

|

Mesh size |

80-120Mesh |

100 |

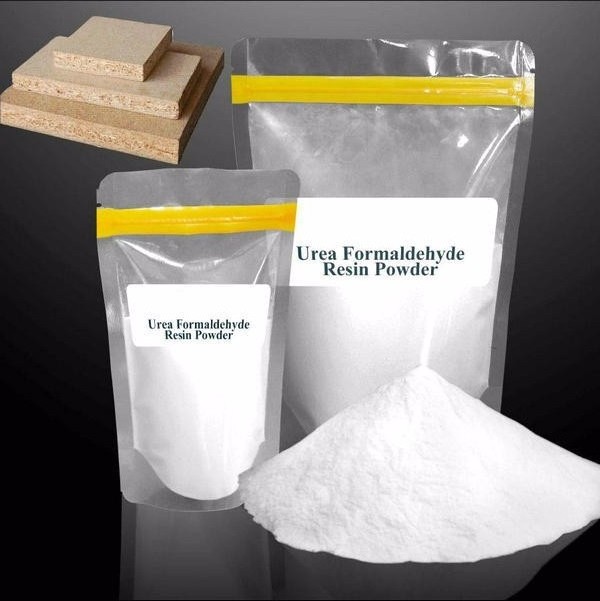

Application

These resins cure easily and are scratch resistant. They are mainly used in adhesives, finishes, particle board, MDF, and molded objects. UF and related amino resins are considered a class of thermosetting resins of which urea-formaldehyde resins make up 80% produced globally.

Usage Method:

1. Pretreatment for gluing wood material:

A) Moisture content reach to 10 + 2%

B) Remove Knots, Cracks, oil stain and resin etc.

C) Wood surface must be flat and smooth. (Thickness Tolerance<0.1mm)

2. Mixture:

A) Mixture Ratio (weight): UF Powder: Water=1: 1(Kg)

B) Dissolution Method:

Put 2/3 of the total needed water into mixer, and then add UF powder in. Switch on the mixer with speed of 50~150 rotations / minute, after glue powder being completely dissolved in water, put the remained 1/3 water in mixer and stir for 3~5minutes till glue to being completely dissolved.

C) Workable period of dissolved liquid glue is 4~8 hours under room temperature.

D) The user could add hardener into the mixed liquid glue according to actual requirement and control the active period of dissolved (if add hardener, the period of validity will be short, and if use under a heat temperature, no need to add hardener)

Storage:

- 1. Powder urea formaldehyde resin should be kept under seal to avoid direct sunlight and to prevent contact with moisture

- 2. Powder urea formaldehyde resin accidentally splashed into the eyes, use plenty of water washing, if necessary, seek advice

- 3. Powder urea formaldehyde resin, easily absorbing moisture, moisture absorption to form solid blocks quickly after the loss of effectiveness and mobility, generally use the moisture-proof packaging. They could ever use when you want to re-truss sealed bags.

- 4. Shelf life: 20°C (68°F) 12 months and 30°C (88°F) 6 months Room temperature, dry and cool place, sealed

Lisa:86+15753803003