- Product Details

- {{item.text}}

Quick Details

-

Model Number:

-

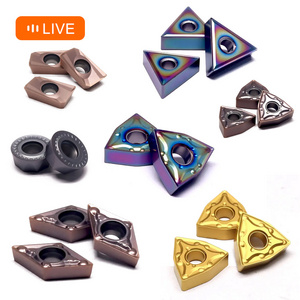

Various types of carbide stone cutting inserts

-

Products:

-

OEM Factory Widia Inserts/ Chainsaw Carbide Tips/Stone Cutting Inserts

-

Aplication:

-

for cutting of various kinds of stones in quarry

-

Material:

-

tungsten carbide virgin materials

-

Shape:

-

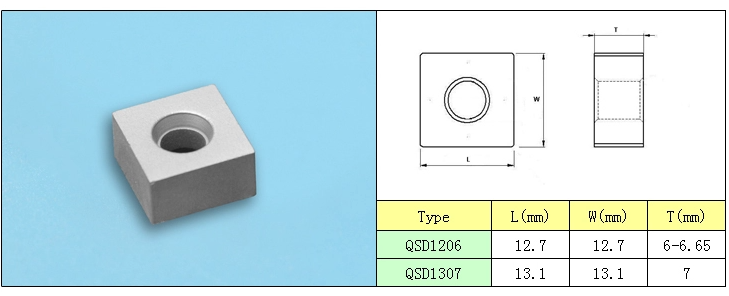

rectangular, square, star shape or custome shape

-

Recommend Grade:

-

KG8/K20/K30/K40/YC20/YC15

-

Transportation:

-

By courier or by shipment,by air

-

Origin:

-

Zhuzhou city in China

-

Surface:

-

Sintered,sand blasted and grind

-

Main types:

-

12.7x12.7x6.5,13.1x13.1x4.5-7,19.6x11.9x2.9,20x12x3.35-3.5 etc.

-

Packing:

-

Plastic box inside with carton outside

Quick Details

-

Warranty:

-

1 year

-

Place of Origin:

-

Hunan, China

-

Brand Name:

-

Kerui carbide stone cutting inserts

-

Model Number:

-

Various types of carbide stone cutting inserts

-

Products:

-

OEM Factory Widia Inserts/ Chainsaw Carbide Tips/Stone Cutting Inserts

-

Aplication:

-

for cutting of various kinds of stones in quarry

-

Material:

-

tungsten carbide virgin materials

-

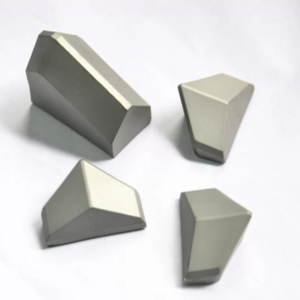

Shape:

-

rectangular, square, star shape or custome shape

-

Recommend Grade:

-

KG8/K20/K30/K40/YC20/YC15

-

Transportation:

-

By courier or by shipment,by air

-

Origin:

-

Zhuzhou city in China

-

Surface:

-

Sintered,sand blasted and grind

-

Main types:

-

12.7x12.7x6.5,13.1x13.1x4.5-7,19.6x11.9x2.9,20x12x3.35-3.5 etc.

-

Packing:

-

Plastic box inside with carton outside

OEM Factory Widia Inserts/ Chainsaw Carbide Tips/Stone Cutting Inserts

We are profesional manufacturer of tungsten carbide stone cutting inserts,welcome to contact us for more details.

| Product Name | Widia Carbide Insert for Quarrying Stone |

| Material | Advanced quality tungsten carbide |

| Finish | As sintered(blank), ground all over |

| Grade | YG6X, YG6, YG8, YG10C, YG11C etc |

| Usage | For chain saw stone cutting. |

| Package | 10 pcs comes in a pvc box or 100pcs in one carton box |

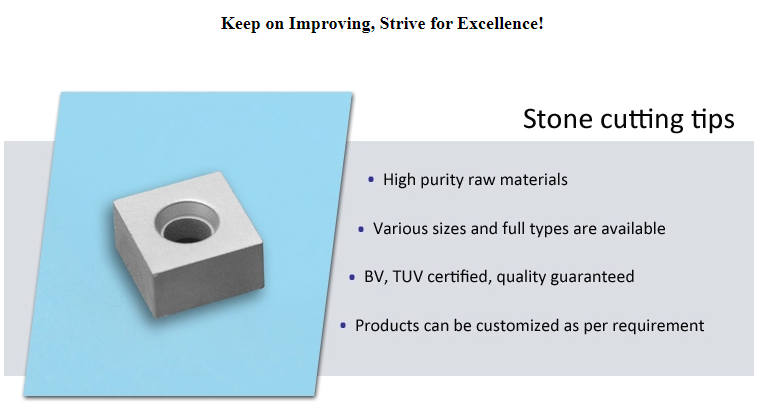

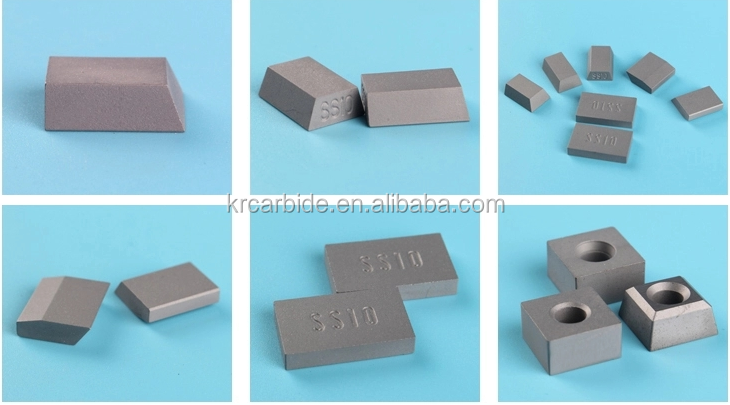

Product Features of OEM Factory Widia Inserts/ Chainsaw Carbide Tips/Stone Cutting Inserts

As for carbide stone cutting tips , below are the general features for your reference. For more details of specific type, please inform us.

1) Made of selective raw material, have more stable properties and longer life time;

2) Special grades for different stones and countries, can provide optimum solutions for customers;

3) Improved process, ensuring higher strength, therefore decreases possibility of crack;

4) Pressed with precision molds, therefore have better dimensional accuracy;

5) Performed careful surface treatment, the products have better appearance;

6) Full range of sizes available, saving cost and delivery time;

7) Top manufacturer in China with over 10 years’ experience.

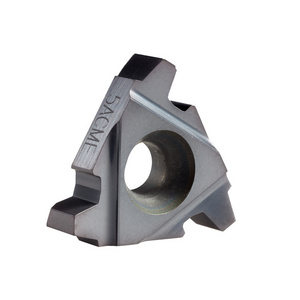

Product Types and Grades of OEM Factory Widia Inserts/ Chainsaw Carbide Tips/Stone Cutting Inserts

Below are the product picture and drawing for your reference. For more details, please inform us.

Main Types Of Stone Cutting Inserts

| Grade for Tungsten Carbide Stone Cutting Tool Tips Inserts | ||||

| Grade | Recommend Application | |||

| KR20 | for processing of limestone, marble, travetine stone, mainly for chain saw | |||

| KR30 | for processing of limestone, marble, travetine stone, mainly for chain saw | |||

| KD11 | for processing of marble, mainly used in Palestine | |||

| KD18 | for processing of marble, mainly used in Palestine | |||

| KG8 | for processing of limestone, tufa, mainly used in Kenya | |||

| YC15 | for processing of limestone, mainly used in Italy, Egypt | |||

| YC20 | for processing of limestone and tufa, mainly used in Kenya and Azerbaijan | |||

Product Application of Stone Cutting Inserts/Tips

For carbide stone cutting inserts, we can supply various sizes as per customers' requirest.

welcome to share your ideal type with us.

Production Process of OEM Factory Widia Inserts/ Chainsaw Carbide Tips/Stone Cutting Inserts

Below are the production processes of carbide stone cutting inserts, to ensure high quality, we assureed our customers that:

1. All raw materials are tested in terms of density, hardness and T.R.S before use.

2. Every piece of product goes through in-process and final inspection.

3. Every batch of product can be traced.

Packing of Tungsten Carbide Inserts for Stone Cutting

All goods would be checked well and packed safely before shipping.

Shipping of Stone Cutting Carbide Inserts