- Product Details

- {{item.text}}

Quick Details

-

Weight (KG):

-

1000

-

Marketing Type:

-

Hot Product 2023

-

Product name:

-

sand dryer

-

Usage:

-

Drying Wet Raw Material

-

Advantage:

-

Easy Operation High Efficiency

-

After-sales Service Provided:

-

Online Support

-

Package:

-

Wooden Case

-

Certification:

-

CE ISO

-

Feature:

-

Low Energy High Efficiency

-

Color:

-

Customized Color

-

Dryig process:

-

Continuous Automatic Drying

Quick Details

-

Type:

-

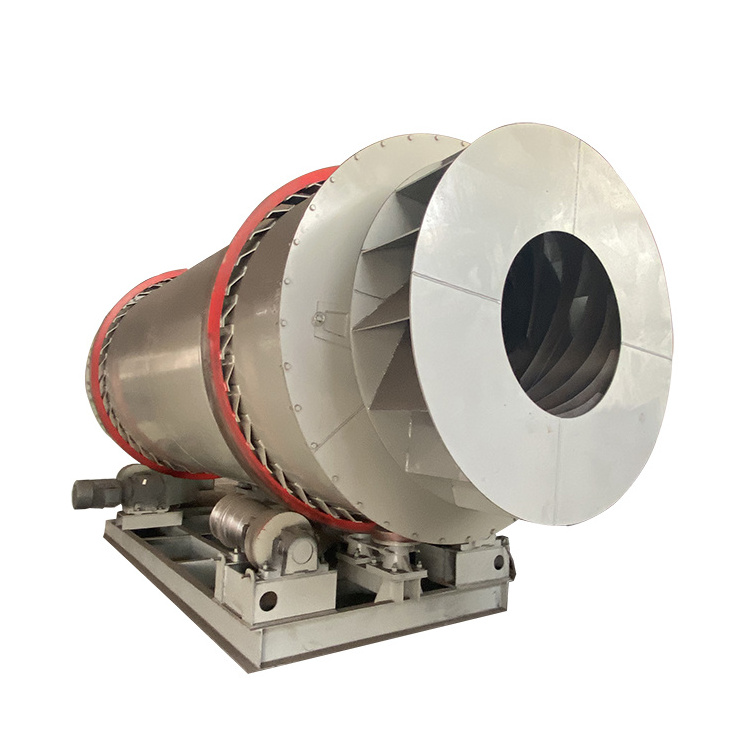

Drum Drying Equipment

-

Place of Origin:

-

Henan, China

-

Brand Name:

-

EVERSUN

-

Weight (KG):

-

1000

-

Marketing Type:

-

Hot Product 2023

-

Product name:

-

sand dryer

-

Usage:

-

Drying Wet Raw Material

-

Advantage:

-

Easy Operation High Efficiency

-

After-sales Service Provided:

-

Online Support

-

Package:

-

Wooden Case

-

Certification:

-

CE ISO

-

Feature:

-

Low Energy High Efficiency

-

Color:

-

Customized Color

-

Dryig process:

-

Continuous Automatic Drying

Products Description

Product description

Three-cylinder dryer equipment can dry dry mortar, yellow sand, cement slag, clay, gangue, mixture, fly ash gypsum, iron powder and other raw materials, widely used in building materials, chemicals, castings, etc.industry.The three-cylinder dryer improves the internal structure of the original single-barrel dryer, increases the pre-drying of the wet material before entering the machine and prolongs the drying time of the wet material in the machine, plus sealing, heat preservation and reasonable supporting measures to make the dryer dry. Machine production capacity is 48-80% higher than the original single drum dryer. Evaporation intensity per unit volume up to 120-180kg/m3, it has advanced technology, reasonable operating parameters, simple and feasible operation.

Working principle

1. The material first goes into the inside drum, because there are the spiral shape boards fixed in the drum, when the dryer make rotary working, the spiral shape board will stir the material and make the material do movement.

2. When the material reaches the right side of the drum, it will go into the second drum for further drying.

3. The same working principle, the material then goes into outside drum, during the drying working process, the material will make three times drying, so the material can be dried completely in this process.

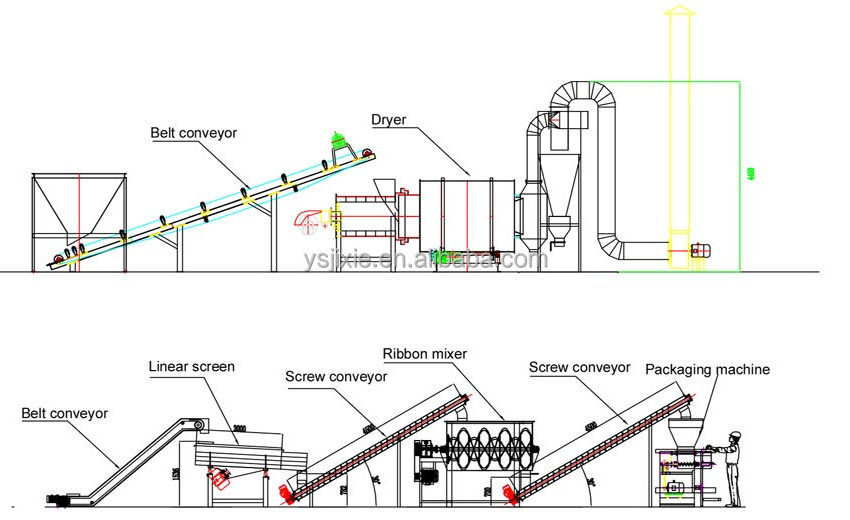

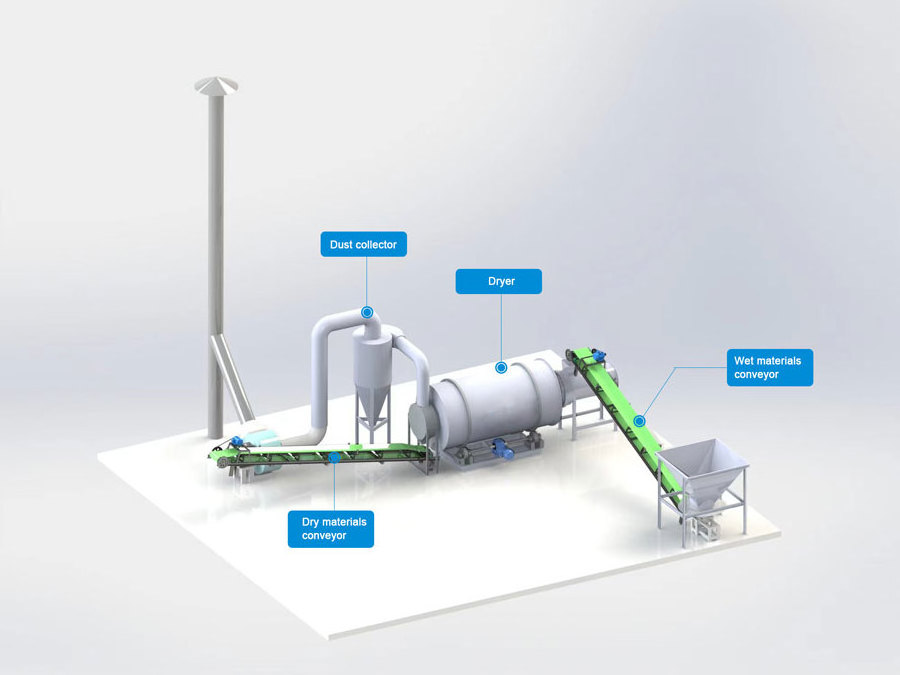

The picture below is the sand production line we designed for our Trinidad customer.

Production process:

1. Belt conveyor transport wet sand into the dryer, and finally get dry sand.

2. The belt conveyor transmits the dry sand to the linear screen for screening.

3. Then, the screw conveyor transmits the screened sand to the ribbon mixer for mixing.

4. Finally, the screw conveyor transports the mixed sand to the packaging machine for packaging.

Details Images

Product Parameters

Application

Packing & Delivery

Hot Searches