- Product Details

- {{item.text}}

Quick Details

-

Core Components:

-

pipeline, thermometer

-

Brand Name:

-

CHENG JINLAI MECHANICAL

-

Dimension(L*W*H):

-

2.1*2.1*2.4M

-

Voltage:

-

380V

-

Applicable Industries:

-

forestry, Wood industry, Furniture Factory

-

Weight (KG):

-

1200

-

Product name:

-

square continuous working carbonization furnace

-

Production Capacity:

-

1-1.5T

-

Applicable raw materials:

-

Bamboo, coconut shell, log, rice husk,wood chips, etc.

-

aw material size:

-

Within 30cm

-

aftersale service provided:

-

Engineers available to service machinery overseas

-

Materials:

-

Carbon Steel

-

Color:

-

Customer's Request

-

Heat source material:

-

Coal, wood, natural gas, diesel, etc.

-

Carbonization method:

-

Dry distillation carbonization

-

Carbonization time:

-

Decide time based on raw materials

Quick Details

-

Place of Origin:

-

Henan,China

-

Marketing Type:

-

New Product 2023

-

Warranty of core components:

-

1 years

-

Core Components:

-

pipeline, thermometer

-

Brand Name:

-

CHENG JINLAI MECHANICAL

-

Dimension(L*W*H):

-

2.1*2.1*2.4M

-

Voltage:

-

380V

-

Applicable Industries:

-

forestry, Wood industry, Furniture Factory

-

Weight (KG):

-

1200

-

Product name:

-

square continuous working carbonization furnace

-

Production Capacity:

-

1-1.5T

-

Applicable raw materials:

-

Bamboo, coconut shell, log, rice husk,wood chips, etc.

-

aw material size:

-

Within 30cm

-

aftersale service provided:

-

Engineers available to service machinery overseas

-

Materials:

-

Carbon Steel

-

Color:

-

Customer's Request

-

Heat source material:

-

Coal, wood, natural gas, diesel, etc.

-

Carbonization method:

-

Dry distillation carbonization

-

Carbonization time:

-

Decide time based on raw materials

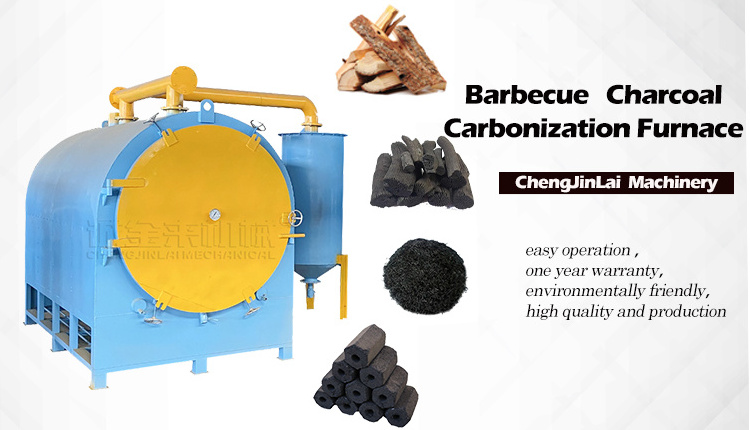

New type industrial charcoal making kiln square continuous working carbonization furnace wood briquette carbonization furnace

Product Description

Horizontal charcoal furnace

is an endothermic charcoal furnace, can carbonize a variety of raw materials, such as

logs, trimmings, bamboo, coconut shells and other shapes but then larger materials

,the process of charcoal carbonization does not require the addition of any energy, the carbonization of the flue gas is fully combusted,

no pollution of the environment

, the use of preheating is full.

Features:

1.Save fuel and high efficiency.

2.No smoke and dust.

3.Applicable to a variety of materials

.

|

Model

|

Inner cylinder size(Diam x Length)

|

Dimension(m)

|

Weight(kg)

|

Output

|

||||

|

CJL-50

|

0.5*0.75m

|

1.1*0.7*1m

|

130

|

50-100kg

|

||||

|

CJL-250

|

1*1.5m

|

1.8*1.2*1.6m

|

450

|

200-300kg

|

||||

|

CJL-500

|

1.5*1.5m

|

1.8*1.7*2.2m

|

1000

|

500-600kg

|

||||

|

CJL-1000

|

1.5*3m

|

3.8*1.8*2.4m

|

2800

|

1500kg

|

||||

|

Support customization

|

|

|

|

|

||||

Working principle

:

Using the flue gas produced by the internal combustion of materials for secondary heating calcination and bomb thermal energy recycling, to achieve the effect of net smoke, circulation, fuel saving, and also collects the acetic acid, tar, gas produced by the material.

Product Details

We have a large number of stock, welcome to purchase!

Can be customised.

Working Process

1,Horizontal charcoal furnace in the burning of log charcoal, the wood should be placed in the furnace in order first.

2,After the fire starts, as the temperature rises, continue to add fuel rods. Keep an eye on the temperature gauge and always remember to open the valve.

3,When the temperature reaches a certain point, combustible gases are produced, reducing the number of sticks added.

4,When the combustible gases have burned out, wait for the temperature to drop to about 50 degrees and open the door to collect the charcoal.

Raw material & Final products

1.Metal recycling: aluminum capacitor recycling, circuit board recycling, waste wire recycling.

2.Biomass carbonization:carbonization of biological wastes such as coconut shell, palm shell, hemp,sawdust and so on.

3.Recycling waste clothes to make carbon powder particles.

Product line:

Packing&Shipping

1,

Small size equipment is packed by wooden case which delivery by LCL shipping .

2, Big size equipment is nude packing which delivery by full container load,small parts will be packed into wooden case.

3, Special packing requirement as customers requirement.

3, Special packing requirement as customers requirement.

Factory Profile

Our advantages:

1.

Factory size over 10,000 square meters;

2.More than 20 national patents,through ISO,TUV,CE and other quality system certification.

Warmly welcome customers to visit our company!

FAQ

Related Products

Hot Searches