- Product Details

- {{item.text}}

Quick Details

-

Voltage:

-

380v, 50hz, 3 phase

-

Weight (KG):

-

6500 KG

-

Product name:

-

tyre retreading machine

-

Function:

-

tyre retreading machine in south africa

-

Name:

-

truck tyre retreading machine

-

Type:

-

tractor tyre retreading machine

-

Application:

-

retreading machine tyre

-

Usage:

-

motorcycle tyre retreading machine

-

Machine Type:

-

motorcycles tyre retreading remold machine

-

Model:

-

tyre-retreading-machine-in-south-africa

-

Product Type:

-

tyre retreading machine automatic

-

Keywords:

-

tyre retreading machinery product

Quick Details

-

Place of Origin:

-

Henan, China

-

Brand Name:

-

YUGONG

-

Marketing Type:

-

Hot Product 2022

-

Voltage:

-

380v, 50hz, 3 phase

-

Weight (KG):

-

6500 KG

-

Product name:

-

tyre retreading machine

-

Function:

-

tyre retreading machine in south africa

-

Name:

-

truck tyre retreading machine

-

Type:

-

tractor tyre retreading machine

-

Application:

-

retreading machine tyre

-

Usage:

-

motorcycle tyre retreading machine

-

Machine Type:

-

motorcycles tyre retreading remold machine

-

Model:

-

tyre-retreading-machine-in-south-africa

-

Product Type:

-

tyre retreading machine automatic

-

Keywords:

-

tyre retreading machinery product

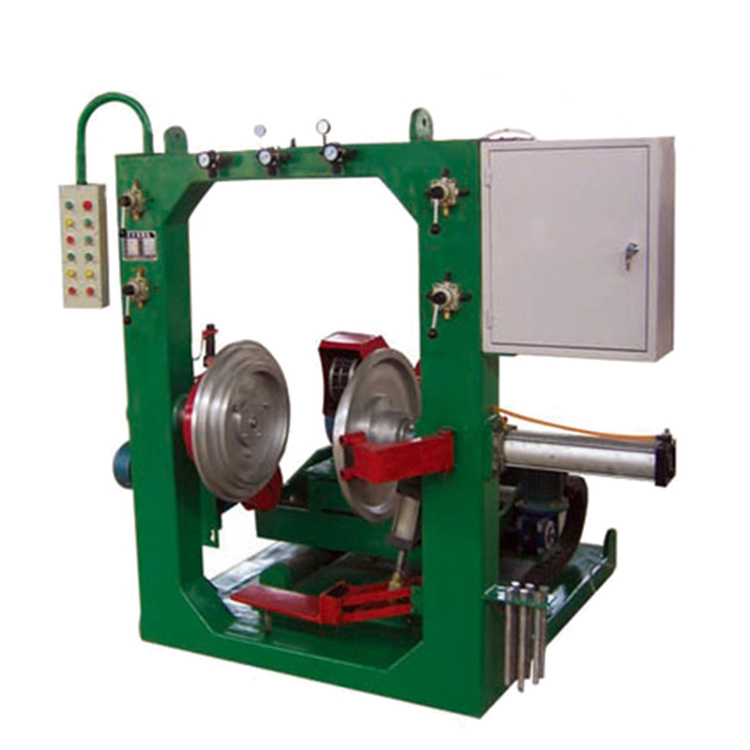

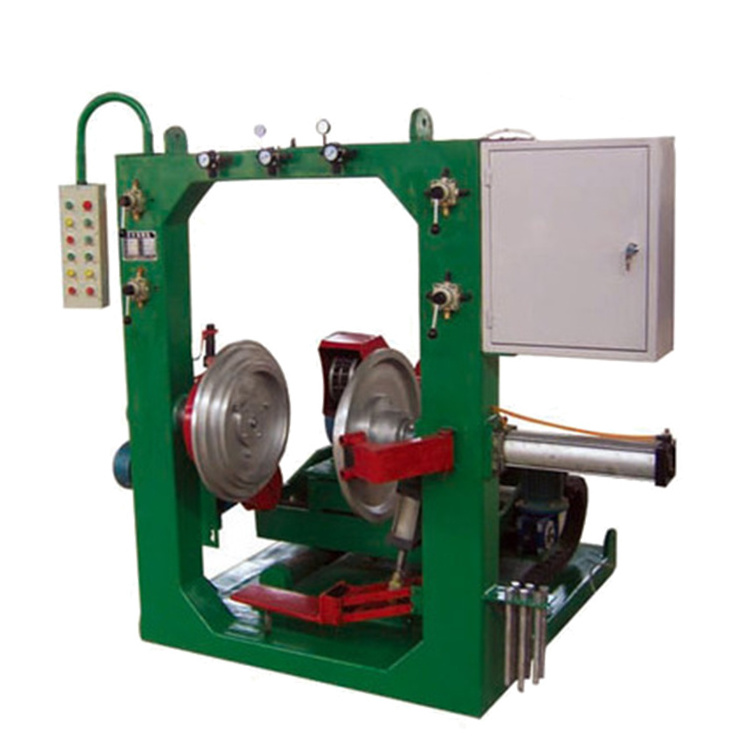

Retread Machine 50-80 Casings/day Hot and Cold Truck Tire Tyre Retreading Production Line

Product Description

Description of Hot Tire Segmented Vulcanizing Cold Truck Tyre Retreading Machine in South Africa

Tire recycling line can be used to recover tires in the 400-3000mm diameter range according to customer requirements. It has strong applicability, and the discharge size can be controlled within the range of 5-100 mm, and the output can reach 200-10000 kg/h. Customized service production can also be carried out according to actual needs. It is composed of a variety of combined equipment, which can separate rubber, steel wire and fiber materials in trolley tires, engineering tires, truck tires and rubber products. The rubber can be processed into pellets or milled. The whole line adopts PLC control system, which is easy to operate and maintain, and has the characteristics of low energy consumption and long service life.

Product Advantages

Advantages of Customized Automatic Electric Heating Truck Tyre Retreading Vulcanizing Machine

1 Easy-handing and safety

2 Advantage design

3 Almost full automatic control

4 equality heat and good heat distribution

5 Durable and reliable

2 Advantage design

3 Almost full automatic control

4 equality heat and good heat distribution

5 Durable and reliable

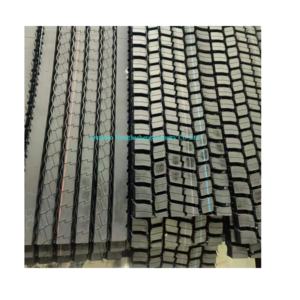

Tyres Retread Production Line Benefits

Benefits of Rubber Extruder Gun Tire Retreading Automatic Tractor Tyre Retreading Machine

The benefits of retreading are that it is both environmentally friendly and cost-efficient! When the tread has worn off, only about 20% of the tyre is used up. The carcass, which represents about 80% of the tyre's value, can be re-rubberized for a "new "tyre life". To produce a truck or bus tyre requires about 60-80 kg of rubber mixture. Retreading the tyre takes only about 15 kg of rubber. A considerable amount of raw materials can therefore be saved. In the EU, this equates to more than 300,000 tones per year! To produce a car tyre requires about 28 litres of crude oil. To retread a car tyre, on the other hand, only 5.5 litres of oil are needed

Our Company

Hot Searches