- Product Details

- {{item.text}}

Quick Details

-

Material:

-

standard export package, 304 Stainless Steel

-

Weight:

-

2000kg

-

Size:

-

4050*1770*2250mm

-

Power:

-

1.49

-

Productivity:

-

100-188kgds/h

-

Weight (KG):

-

2000 kg

-

Product name:

-

Sludge Dewatering Machine

-

Application:

-

municipal & industrial

-

Capacity:

-

100-188kgds/h

-

Color:

-

Customers Demands

-

Filter Media:

-

filter cloth

-

Certification:

-

CE Certificate

-

Packing:

-

Wooden Box

Quick Details

-

Marketing Type:

-

Hot Product 2024

-

Place of Origin:

-

Jiangsu, China, JIA

-

Brand Name:

-

Ryde

-

Material:

-

standard export package, 304 Stainless Steel

-

Weight:

-

2000kg

-

Size:

-

4050*1770*2250mm

-

Power:

-

1.49

-

Productivity:

-

100-188kgds/h

-

Weight (KG):

-

2000 kg

-

Product name:

-

Sludge Dewatering Machine

-

Application:

-

municipal & industrial

-

Capacity:

-

100-188kgds/h

-

Color:

-

Customers Demands

-

Filter Media:

-

filter cloth

-

Certification:

-

CE Certificate

-

Packing:

-

Wooden Box

Product Description

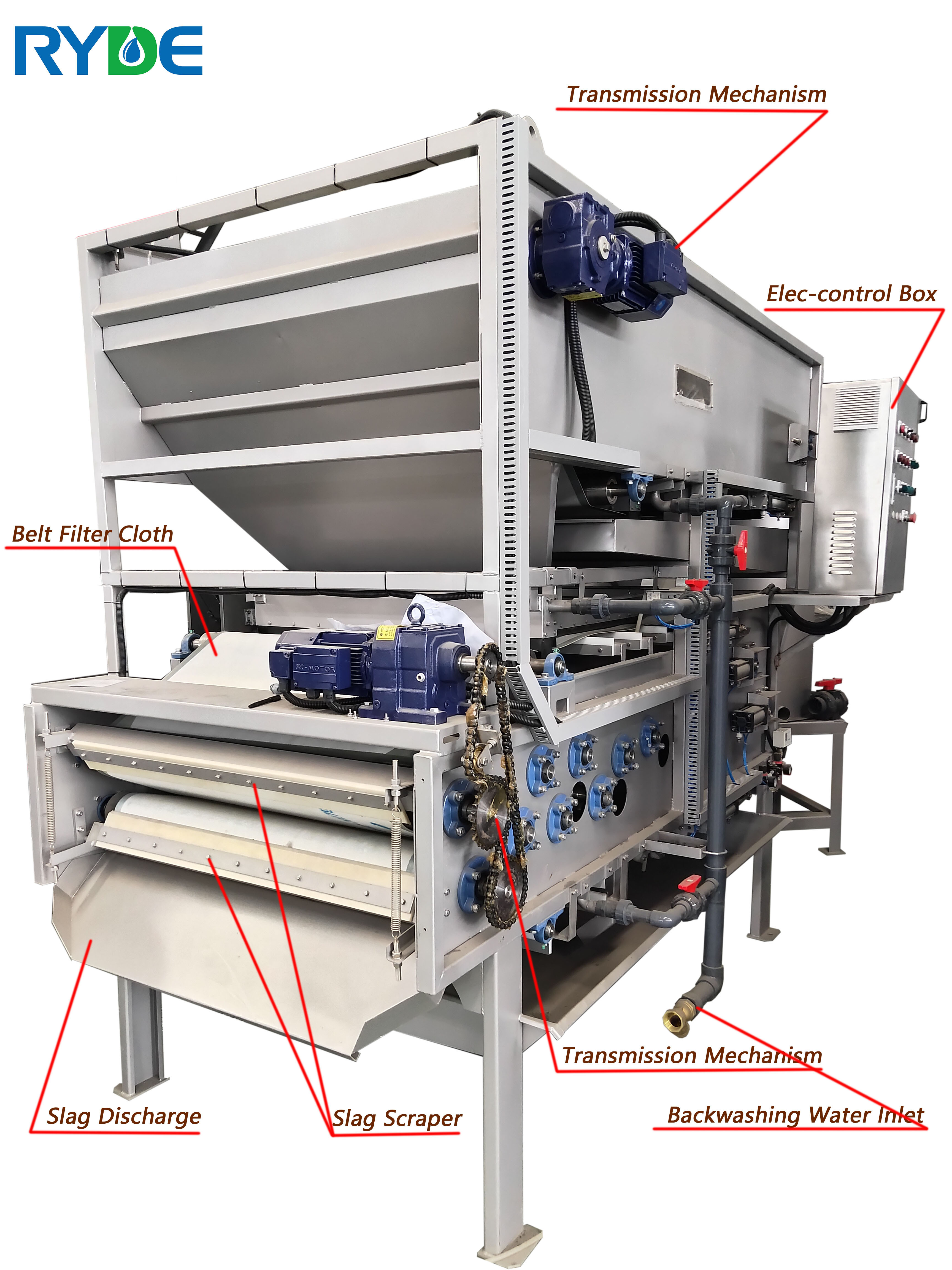

high efficiency Press Waste Water And Effluent Treatment Plant Dewatering Belt Filter Press For Paper Industry

What is a Belt Filter Press?

A Belt Filter Press is a sludge dewatering device that applies mechanical pressure to a chemically conditioned slurry, which is sandwiched between two (2) tensioned belts, by passing those belts through a serpentine of decreasing diameter rolls. The machine can actually be divided into three (3) zones: the gravity zone, where free draining water is drained by gravity through a porous belt; the wedge zone, where the solids are prepared for pressure application; and the pressure zone, where medium, then high pressure is applied to the conditioned solids.

Product Paramenters

Working principle

Its operating principle is to condition the feed sludge with a polyelectrolyte and drain the flocculated sludge over an endless, horizontal porous filter belt. The thickened sludge is then sandwiched by a second filter belt before further dewatering by a series of decreasing diameter rollers. Final moisture removal is achieved by shear rollers arranged to give minimum 180 degree belt wrap in order to optimize dewatering.

|

Model

|

|

ZDY1000

|

ZDY1500

|

ZDY2000

|

Remark

|

|||||

|

Belt Width (mm)

|

|

1000

|

1500

|

2000

|

|

|||||

|

Treating Capacity (m³/h)

Inlet Consistency (S.S1-2%) |

|

5-10

|

8-16

|

12-24

|

Depends on Sludge Category

|

|||||

|

Dried Sludge (kg/h)

|

|

70~120

|

120~220

|

180-320

|

Depends on Sludge Category

|

|||||

|

Mud Cake Water Content's Rate (%)

|

|

75-85

|

75-85

|

75-85

|

Depends on Sludge Category

|

|||||

|

Power Consumption (kw)

|

Driving Motor (frequency control)

|

0.37

|

0.75

|

0.75

|

|

|||||

|

|

Disposal Agitaor Motor

|

0.37

|

0.55

|

0.75

|

|

|||||

|

|

Drum thickener

|

0.75

|

0.75

|

1.1

|

|

|||||

|

Lower Collecting Tray for Pressed Filtrate

|

|

Yes

|

Yes

|

No

|

|

|||||

|

External Dimensions (mm)

|

L

|

2600

|

2600

|

3450

|

Please ask for actual installation size picture before purchasing

|

|||||

|

|

W

|

1550

|

2150

|

2900

|

|

|||||

|

|

H

|

2540

|

2550

|

3100

|

|

|||||

|

Dase Dimension L1*W1(mm)

|

|

2100*1330

|

2450*1860

|

2715*2420

|

|

|||||

|

Dase Dimension L2*W2 (mm)

|

|

640*800

|

740*800

|

950*1100

|

|

|||||

|

Reference Weight (kg)

|

|

1000

|

1600

|

2850

|

|

|||||

|

Customization Accepted

|

|

|

|

|

|

|||||

Note: Yangzhou Ryde Environment keeps the rigfht to optimize and change the parameters.

We

provide free customized solution services!

The final price shall be based on the proposed quotation!

Application & Successful Cases

Yangzhou Ryde Belt Filter Press is a sludge dewatering machine suitable for all municipal wastewater sludge types and a wide variety of industrial solid / liquid separation applications, such as paper, petrochemical, mineral, food processing, pharmaceutical and chemical. The G3 belt press incorporates variable energy mixing, flocculation, gravity drainage and pressure filtration within a single mechanical framework.

The belt press offers the versatility of a wide size range and extensive modular options to meet individual process

requirements.

The belt press offers the versatility of a wide size range and extensive modular options to meet individual process

requirements.

Hot Searches