- Product Details

- {{item.text}}

Quick Details

-

Material:

-

Aluminum, Steel, Rubber

-

Brand Name:

-

TAIGU

-

Place of Origin:

-

Guangdong, China

-

Surface processing::

-

Hard anodised

-

Material::

-

Two ends with aluminium, the middle bellows with stainless steel.

-

color::

-

Black Oxide Finish

-

Speciality::

-

Clamping Screw type

-

Certification:

-

ISO9001:2000

Quick Details

-

Applicable Industries:

-

Garment Shops, Manufacturing Plant, Machinery Repair Shops, Farms, Restaurant, Home Use, Retail

-

Structure:

-

Spider, Disc, Gear, Metal Bellows, Oldham, Roller chain, Universal

-

Standard or Nonstandard:

-

Standard

-

Material:

-

Aluminum, Steel, Rubber

-

Brand Name:

-

TAIGU

-

Place of Origin:

-

Guangdong, China

-

Surface processing::

-

Hard anodised

-

Material::

-

Two ends with aluminium, the middle bellows with stainless steel.

-

color::

-

Black Oxide Finish

-

Speciality::

-

Clamping Screw type

-

Certification:

-

ISO9001:2000

Rigid Shaft Couplings

Apply to screw, servo motors, stepper motors, micro motor, encoder high-end coupling ( Accept non-calibrated as one's requirements)

Flexible Coupling Introduction:

Flexible couplings are offered in the industrys largest variety of stock bore/keyway combinations. These couplings require no lubrication and provide highly reliable service for light, medium, and heavy duty electrical motor and internal combustion power transmission applications. Applications include power transmission to industrial equipment such as pumps, gear boxes, compressors, blowers, mixers, and conveyors.

Rigid Coupling Introduction:

is a unit of hardware used to join two shafts within a motor or mechanical system.

It may be used to connect two separate systems, such as a motor and a generator, or to repair a connection within a single system. It may also be added between shafts to reduce shock and wear at the point where the shafts meet.

Steel-Black Oxide Finish, Stainless Steel

OEM service.

| Applications: |

| 1. Widely used in various mechanical and hydraulic fields |

| 2. Small dimension, low weight, high transmitted torque |

| 3. Elastomers made of polyurethane with shore hardness between 80-98 |

| 4. Compensating the axial relative drift, buffer and vibration reduction |

| 5. Bore tolerance ISO standard H7 |

| 6. Keyway tolerance as per DIN6885/1 JS9 |

| 7. Material: cast iron, steel and aluminum alloy |

| 8. Finishing: blacken, phosphate-coat, and oxidation. |

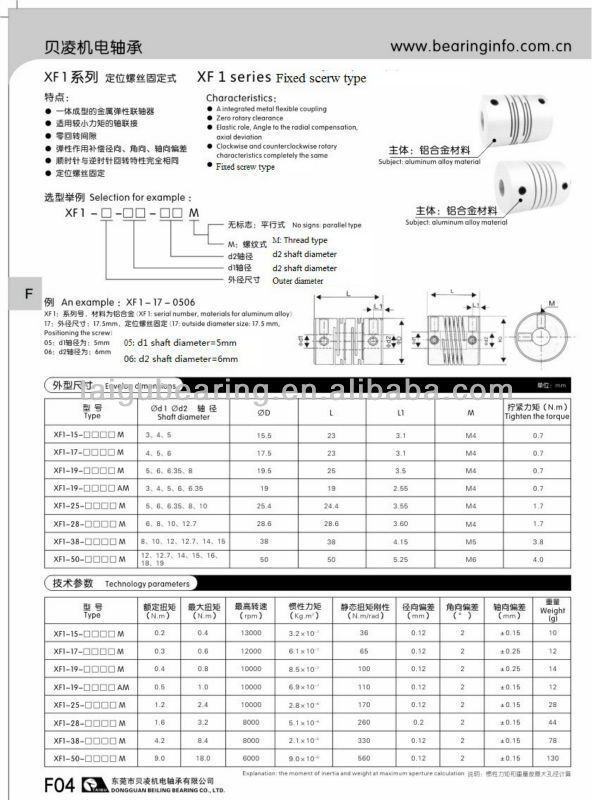

XF1 Series Set screw Parallel type

Characteristic:

l All-in-one metallic spring coupling.

l Smaller torque shaft for connection.

l Zero rotation clearance

l Bellows structure compensation of radial and angular, axial deviation

l Clockwise and counterclockwise rotation characteristics exactly the same

l set screw fixed

For example: XF1-17-0506

l XF1: series No., Aluminum Alloy Material

l 17: outer diameter: 17.5mm, fixed with setscrew.

l 05: d1 shaft diameter 5mm

l 06: d2 shaft diameter 6mm.

| Overal Dimensions | Unite:mm | ||||||||

| Model | d1 d2 Saft Dia | D | L | L1 | F | E | M | Tightening Torque(N.m) | |

| XF6-16C--/-- | 4 5 6 6.35 8 | 16 | 30 | 10.5 | 4.0 | 9.5 | M3 | 0.7 | |

| XF6-20C--/-- | 6 6.35 8 9.525 10 12 | 20 | 33 | 10.5 | 4.0 | 12.5 | M3 | 0.7 | |

| XF6-25C--/-- | 6 6.35 8 9.525 10 12 | 25 | 38 | 12.5 | 5.0 | 15.0 | M4 | 1.7 | |

| XF6-32C--/-- | 8 9.525 10 12 14 | 32 | 43 | 14.0 | 6.0 | 21.0 | M4 | 1.7 | |

| XF6-32CL--/-- | 8 9.525 10 12 14 | 32 | 54 | 14.0 | 6.0 | 21.0 | M4 | 1.7 | |

| XF6-40C--/-- | 10 11 12 14 15 16 | 40 | 62 | 21.5 | 6.5 | 27.0 | M5 | 4.0 | |

| XF6-55C--/-- | 12 14 15 16 19 | 55 | 72 | 23.0 | 7.0 | 40.0 | M6 | 8.0 | |

| XF6-65C--/-- | 18 19 20 24 25 28 30 32 35 38 | 65 | 81 | 25.5 | 9.0 | 45.0 | M8 | 15.0 | |

| XF6-82C--/-- | 20 24 25 28 30 32 35 38 40 42 | 82 | 103 | 34.5 | 11.0 | 56.0 | M10 | 28.0 | |

| Technical Reference | |||||||||

| No. | Rated Torque(N.m) | Max. Torque ( N.m ) | Max. Speed ( rpm ) | Moment of Interia ( Kg.m2 ) |

Static Torque Rigid

( N.m/rad ) |

Radial Deviation ( mm ) | Angular Deviation ( ° ) | Axial Deviation ( mm ) | Weight(g) |

| XF6-16C--/-- | 0.8 | 1.6 | 18000 | 3.4×10-7 | 100 | 0.10 | 1.5 | +0.3 -1.0 | 8 |

| XF6-20C--/-- | 1.5 | 3.0 | 13000 | 8.9×10-7 | 160 | 0.10 | 1.5 | +0.3 -1.0 | 14 |

| XF6-25C--/-- | 2.0 | 4.0 | 11000 | 2.8×104 | 220 | 0.15 | 2.0 | +0.5 -1.3 | 32 |

| XF6-32C--/-- | 2.5 | 5.0 | 10000 | 8.8×104 | 310 | 0.20 | 2.0 | +0.5 -1.3 | 52 |

| XF6-32CL--/-- | 2.5 | 5.0 | 10000 | 8.9×104 | 310 | 0.20 | 2.0 | +0.5 -1.3 | 58 |

| XF6-40C--/-- | 10.0 | 20.0 | 8000 | 1.5×104 | 520 | 0.20 | 2.0 | +0.7 -1.5 | 98 |

| XF6-55C--/-- | 25.0 | 50.0 | 6000 | 2.3×104 | 850 | 0.20 | 2.0 | +0.7 -1.5 | 200 |

| XF6-65C--/-- | 60.0 | 120.0 | 4500 | 2.8×104 | 960 | 0.20 | 2.0 | +0.7 -1.5 | 350 |

| XF6-82C--/-- | 80.0 | 160.0 | 4000 | 6.0×104 | 1290 | 0.20 | 2.0 | +0.7 -1.5 | 750 |