- Product Details

- {{item.text}}

Quick Details

-

Rolling thinckness:

-

0.4-0.9 mm

-

Place of Origin:

-

Hebei, China

-

Brand Name:

-

ZHONGTUO

-

Voltage:

-

220V-3P-50HZ

-

Weight:

-

7000 kg

-

Feeding width:

-

Other

-

Marketing Type:

-

New design 2023

-

Product name:

-

stud and track drywall channel making machine

-

Thickness:

-

0.4-0.9 mm

-

Control system:

-

Delta

-

Shaft material:

-

50 mm

-

Cutting blade material:

-

Cr 12 High Grade Steel

-

Roller stations:

-

14 roller stations

-

Material of rollers:

-

Gcr12 Steel

-

Color:

-

Custimized

-

Decoiler:

-

Manual or hydraulic decoiler

-

Control box language:

-

Add Customer Request Language

Quick Details

-

Type:

-

Tile Forming Machine

-

Tile Type:

-

Steel

-

Production Capacity:

-

50 m/min

-

Rolling thinckness:

-

0.4-0.9 mm

-

Place of Origin:

-

Hebei, China

-

Brand Name:

-

ZHONGTUO

-

Voltage:

-

220V-3P-50HZ

-

Weight:

-

7000 kg

-

Feeding width:

-

Other

-

Marketing Type:

-

New design 2023

-

Product name:

-

stud and track drywall channel making machine

-

Thickness:

-

0.4-0.9 mm

-

Control system:

-

Delta

-

Shaft material:

-

50 mm

-

Cutting blade material:

-

Cr 12 High Grade Steel

-

Roller stations:

-

14 roller stations

-

Material of rollers:

-

Gcr12 Steel

-

Color:

-

Custimized

-

Decoiler:

-

Manual or hydraulic decoiler

-

Control box language:

-

Add Customer Request Language

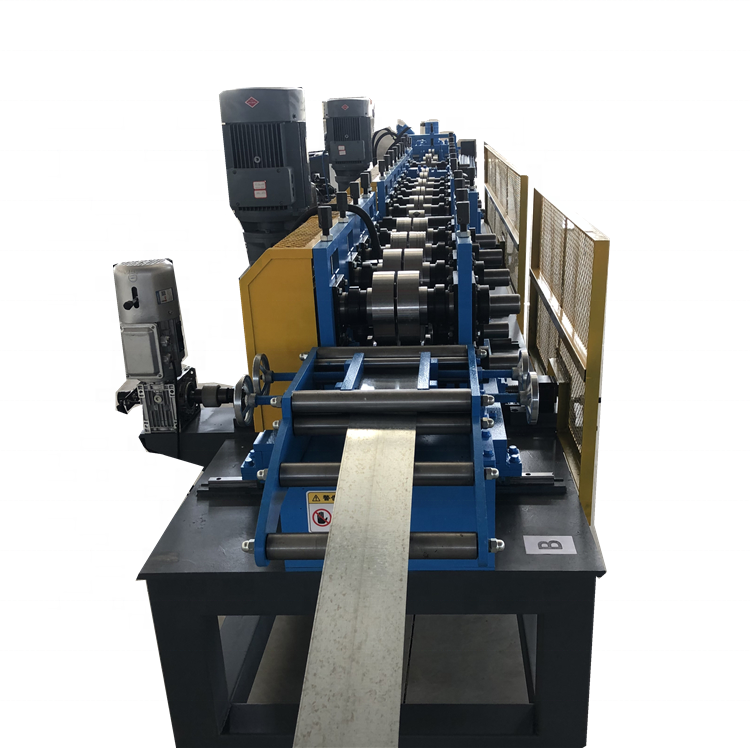

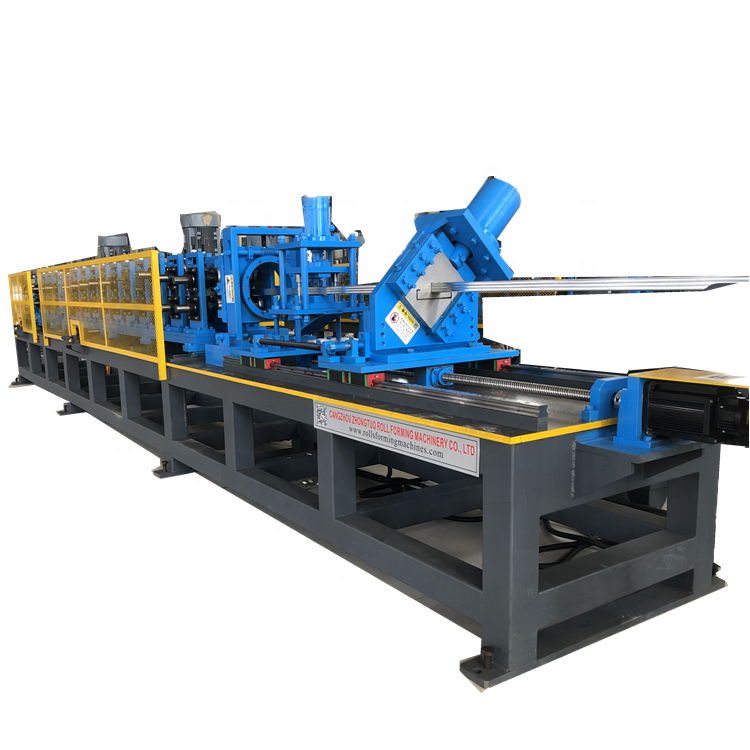

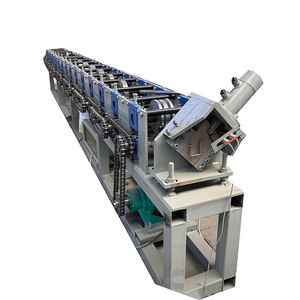

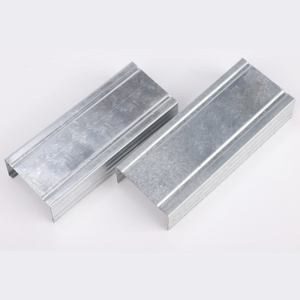

Light duty galvanized metal steel C stud and U track system drywall manufacturing making machine

Feature service of our stud and track drywall profile making machine:

1. Support stud and track dimension customized, machine color and voltage customized as your request.

2. Can punching logos or ribs on channel if you need.

3. Electric parts brand can follow your request.

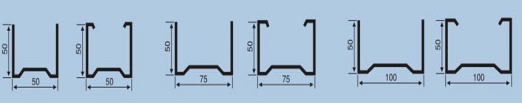

Profile drawing as below

Here is the C and U channel profile drawing and dimensions for your reference. In drywall system, stud will insert into track, so usually stud need punching holes. One machine can produce both C and U sizes by adjust the roller spacer manually or automatically. We have different machine speed for you choose, like 25 m/min, 45 m/min, 70 m/min with semi-automatic and full automatic type.

|

Product

|

|

|

|

Details

|

Parameter

|

|

|

Raw material

|

Galvanized steel

|

|

|

Material thickness

|

0.4-0.9 mm

|

|

|

Cutting length

|

Adjustable

|

|

Decoiler

Work type:Passive type

Loading capacity:3 Tons

Coil inner diameter:450-550 mm (adjustable)

Quantity:1 set

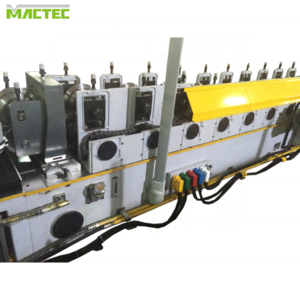

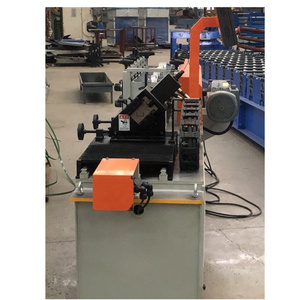

Roll Forming System

Feature;The one side machine frame can be move by PLC control to adjust the stud and truck dimension.

Rolling shaft:

Shaft material: 45# steel

Shaft diameter: 50 mm

Tempering treatment

Roller:

Roller material: Cr12

Quenched treatment

Rolling station number:14 stations

Work speed:0-40 m/min, if punching, 30m/min

Machine frame:Vertical iron arch casting frame structure

Bearing:Chinese famous brand Harbin

Work power:5.5+5.5 kw

Transmission:By chains

PLC Control System

Hydraulic System

Afer-Sale Service

1.Payment: 30%T/T in advance and 70%balance after testing and before shipment.

2.Delivery: 50 working days after the deposit.

3.Validity time: 15 working days

4.After-sales service

A: Warranty: One year ,and we will provide the technical support for the whole life.some spare parts are available.

B: Training and service: the buyer should charge of visa, round-trip ticket, food and accommodation overseas and USD 80/person/day for salary.

C.The advantage of my factory: we have a team of skilled engineers and one group for after-sale service.

D: we will provide you the manual for installation, operation and maintenance in English.

Hot Searches