- Product Details

- {{item.text}}

Quick Details

-

Brand Name:

-

Holsten

-

Dimension(L*W*H):

-

4000mm*2000mm*2000mm

-

Capacity:

-

9CBM

-

Weight:

-

3000

-

Inner Material:

-

cabon steel

-

Outer Material:

-

Cold rolled plate

-

Design Pressure(MPa):

-

1.5

-

Design Standard:

-

GB150/ASME

-

Working Temperature(℃):

-

100 - 200 ℃

-

Name:

-

Automatic large carbon fiber autoclave composite curing oven

-

Material:

-

Carbon Steel

-

Application:

-

Composite material autoclave,carbon fiber,aerospace products

-

Maximum working temperature::

-

200℃

-

Vacuum degree::

-

≤-0.098Mpa

-

Customized:

-

All dimentions, temperatures, pressures, colors can be

-

Key words:

-

Stainless Steel Pressure Tank

-

Function:

-

High Temperature High Pressure

-

Certification:

-

GB150 / ASME

-

Color:

-

Customized

Quick Details

-

Volume (m³):

-

12.56

-

Max Working Pressure(MPa):

-

1.2 MPa

-

Place of Origin:

-

Shandong,China

-

Brand Name:

-

Holsten

-

Dimension(L*W*H):

-

4000mm*2000mm*2000mm

-

Capacity:

-

9CBM

-

Weight:

-

3000

-

Inner Material:

-

cabon steel

-

Outer Material:

-

Cold rolled plate

-

Design Pressure(MPa):

-

1.5

-

Design Standard:

-

GB150/ASME

-

Working Temperature(℃):

-

100 - 200 ℃

-

Name:

-

Automatic large carbon fiber autoclave composite curing oven

-

Material:

-

Carbon Steel

-

Application:

-

Composite material autoclave,carbon fiber,aerospace products

-

Maximum working temperature::

-

200℃

-

Vacuum degree::

-

≤-0.098Mpa

-

Customized:

-

All dimentions, temperatures, pressures, colors can be

-

Key words:

-

Stainless Steel Pressure Tank

-

Function:

-

High Temperature High Pressure

-

Certification:

-

GB150 / ASME

-

Color:

-

Customized

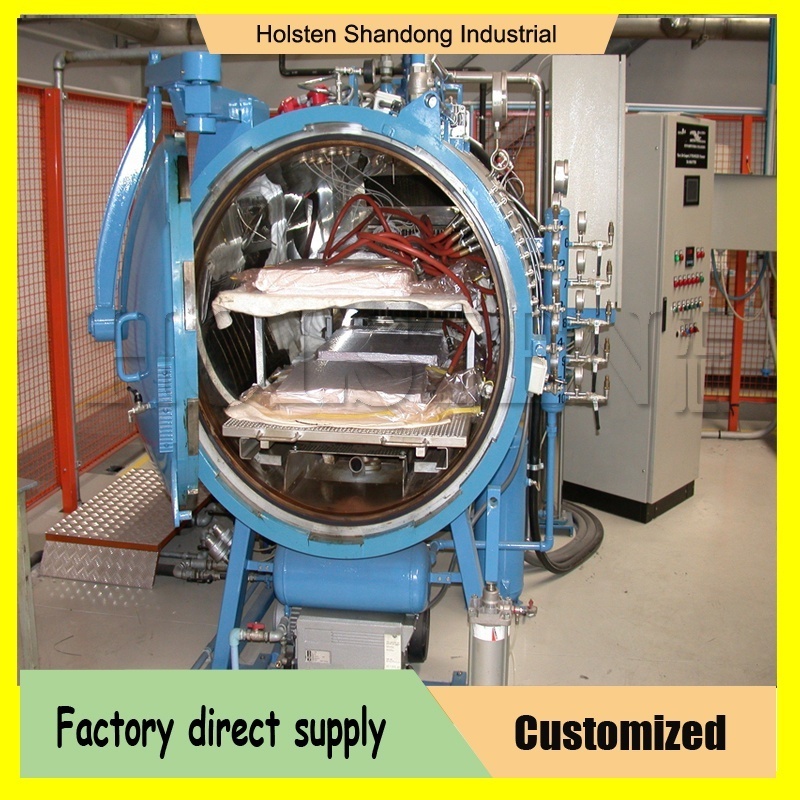

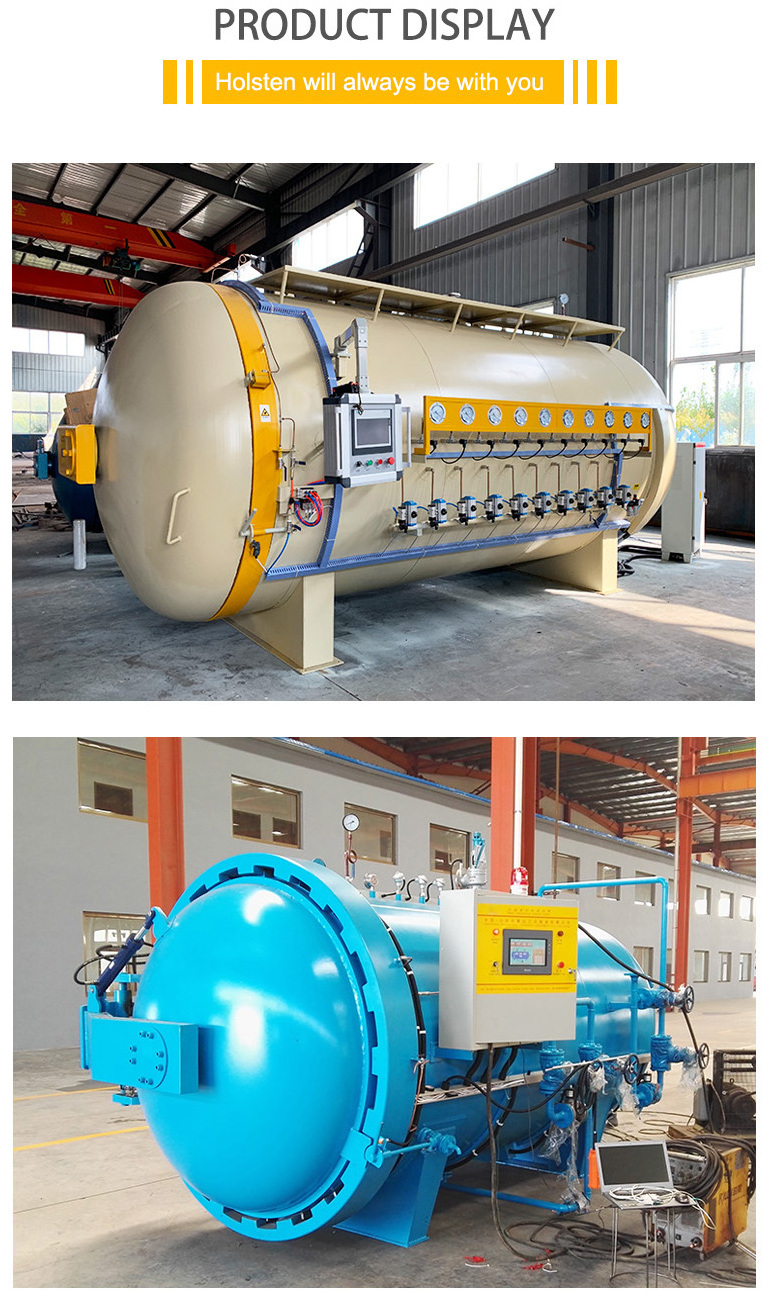

Automatic large carbon fiber autoclave composite curing oven

The autoclave is a special equipment for manufacturing large composite components, which is widely used for curing and forming metal and non-metal bonding components and resin-based carbon fiber composite components in aerospace, sports, automobile, bicycle and other industrial and civil fields.

|

Working diameter |

500mm ~ 5000mm |

|

Working length |

600mm ~ 20000mm |

|

Heating method |

Electric heating air |

|

Ramp temp max |

0-3.5℃/min continuously adjustable |

|

Cooling method |

Water cooling |

|

Cooling rate |

Above 80 ℃ ,0-3.5 ℃ /min continuously adjustable ;below 80 ℃ ,0-2 ℃ continuously adjustable |

|

Temperature |

100 ℃ ~500 ℃ |

|

Temp uniformity |

≤ 2 ℃ |

|

Temp control points |

2~40( optional ) |

|

Pressure |

0.1—4.0MPa |

|

Pressure uniformity |

≤ 0.01MPa |

|

Vacuumize line |

2~40 vacuum lines |

|

Thermo sensors |

2~40 thermo sensors |

|

Vacuum degree |

—0.098MPa |

|

Control method |

Industrial computer / PLC control |

|

Trolley inside and outside the tank |

One internal loading vehicle and one external platform trolley

|

|

Certificate |

GB150 / ASME |

|

Vacuum/air source/cooling water source |

Optional |

Heating mode:

1.Heat conduction oil heating

2.Steam direct heating

3.Electrically heated air

4.Electrically heated steam

Door opening mode:

1.Power-driven

2.Hand-driven

3.Hydrodynamic-driven

4.Various types of vulcanization tank and quick-opening door safety interlocking

devices can be provided separately.(Company advantage)

Q: Are you manufacturer or trading company?

A: We are a

professional

manufacturer.

Q: What is your business scope?

A: There are categories such as vulcanization tank, autoclave tank,

food sterilization pots

, etc.

Q: What if there is something wrong with the machine within one year?

A: We have two ways to solve the problem.

a. Phone call/on-line service to solve the problem.

b. We will take video to show ’how to solve the problem’. All the problems can be solved by video guidance.

Q: How about the installation? And what if the machine goes down?

A: We will do that. There are two options.

a. We could appoint our engineer to your company to install and debug, as for the cost of this trip such as ticket, visa, accommodation and labor cost shall be on your side.

b. On-line service will be provided. If still is under guarantee period, the necessary accessories and parts will be provided free, but the transportation cost of it shall be on your side.