Explore More Products

- Product Details

- {{item.text}}

Quick Details

-

Screw diameter (mm):

-

93 mm

-

Screw Speed (rpm):

-

600 rpm

-

Place of Origin:

-

Jiangsu, China

-

Brand Name:

-

COWIN

-

Voltage:

-

Customized

-

Dimension(L*W*H):

-

Machine Model

-

Power (kW):

-

250

-

Weight:

-

2T

-

Applicable Industries:

-

plastic sheet production

-

Color:

-

Require

-

Power(W):

-

20-500KW

-

Automatic Grade:

-

High Automation

-

weight:

-

2T

-

After-sales Service Provided:

-

Video technical support, Field installation, commissioning and training, Online support

-

After Warranty Service:

-

Video technical support, Online support, Field maintenance and repair service

-

Local Service Location:

-

None

-

Certification:

-

CE Certificate

-

Marketing Type:

-

Hot Product 2021

Quick Details

-

Screw Design:

-

Double-screw

-

Screw L/D Ratio:

-

Other

-

Twin Screw Type:

-

Double-screw

-

Screw diameter (mm):

-

93 mm

-

Screw Speed (rpm):

-

600 rpm

-

Place of Origin:

-

Jiangsu, China

-

Brand Name:

-

COWIN

-

Voltage:

-

Customized

-

Dimension(L*W*H):

-

Machine Model

-

Power (kW):

-

250

-

Weight:

-

2T

-

Applicable Industries:

-

plastic sheet production

-

Color:

-

Require

-

Power(W):

-

20-500KW

-

Automatic Grade:

-

High Automation

-

weight:

-

2T

-

After-sales Service Provided:

-

Video technical support, Field installation, commissioning and training, Online support

-

After Warranty Service:

-

Video technical support, Online support, Field maintenance and repair service

-

Local Service Location:

-

None

-

Certification:

-

CE Certificate

-

Marketing Type:

-

Hot Product 2021

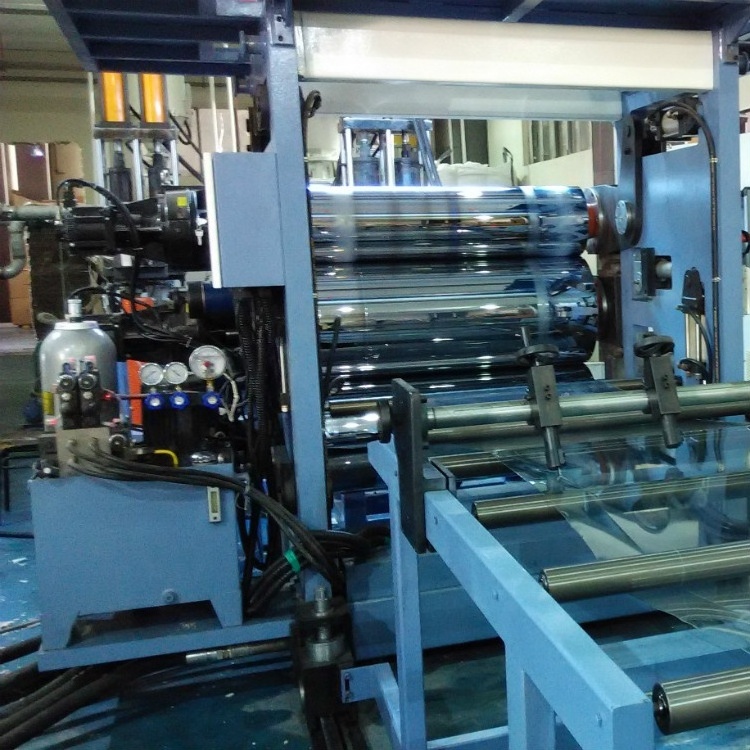

It is PET extrusion with latest generation twin screw extruders – power consumption (energy saving).

PET is a hygroscopic material. At atmosphere condition it absorbs humidity. During the extrusion process the humid material is subject to the hydrolysis chemical reaction that affects the mechanical properties of the extruded foil. For this reason the common technology needs to dry the material with a high level of power consumption.

Using COWIN last generation of twin screw extruders, we can help to avoid the drying process and extrude the PET material, both pellets and flakes, even if they come from a post-consume PET bottle recycling system. The humidity is kept-out through a proper vacuum device installed on the extruder thus avoiding or reducing the hydrolysis process consequences.

COWIN can provide the co-extrusion sheet by means of a proper distributor (Feed Block) that builds the desired geometry of the different layers.

The most common co-extruded foil is made of three layers, "A-B-A" geometry, where "A" is the skin layer obtained with 100% of virgin material and "B" is the core layer obtained with recycled material in flakes. Obviously, the extrusion line must be fitted with two extruders, one for the "A" layer and the other for "B" layer. This technology reduces the costs of the final products.

Features

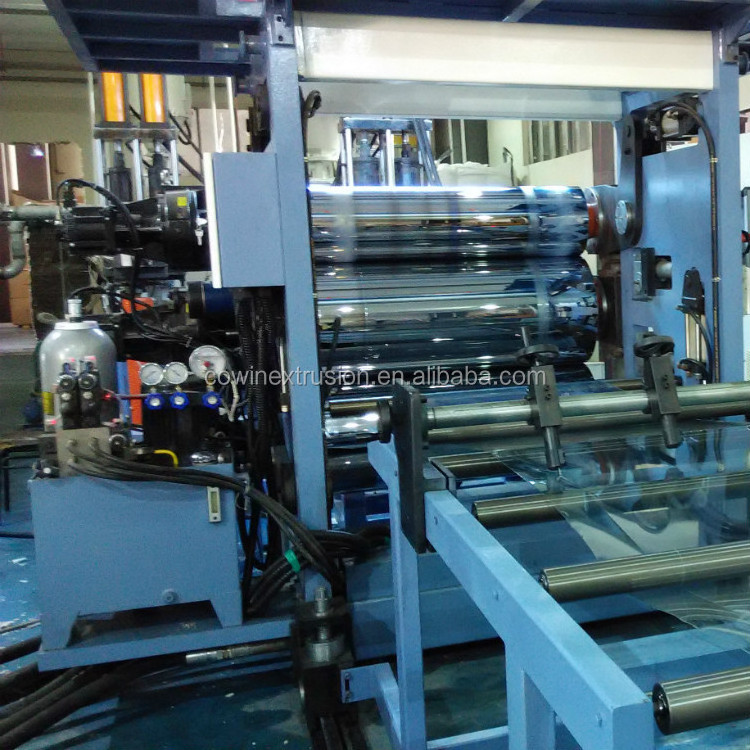

- 1. With twin screw solution, you can remove the pre-drying system and crystallization system. This will save minimum 30% of the energy.

- 2. The final sheet quality is improved as degradation is avoided occurred during hours of pre-crystallization and pre-dry period.

- 3. The process is obviously shortened and simplified, different kinds of recycled or raw material such as APET, PETG and GAG can be directly used, the productivity is significantly improved.

- 4. With COWIN special super vacuum system and proper screw configuration, we can control the IV drop within an acceptable range, normally 0.03 depends on the moisture content.

- 5. With twin screw, you can fully use the extruder capacity. While single screw extruder has a much lower running speed, you will lose more energy to get the same output.

- 6. Single layer sheet or ABA composite sheet both available based on twin screw extruders.

- 7. Both complete new line based on twin screw extruder or technology up-gradation for traditional single screw line available.

Specification

|

model

|

CHT-52

|

CHT-65

|

CHT-75

|

CHT-85

|

CHT-95

|

|

screw diameter

|

51.4

|

62.4

|

71

|

81

|

93

|

|

L/D

|

40

|

40

|

40

|

40

|

40

|

|

screw speed (rpm)

|

266

|

300

|

300

|

266

|

266

|

|

main motor (kw)

|

37

|

75

|

132

|

160

|

250

|

|

barrel heating (kw)

|

23

|

28

|

44

|

55

|

71

|

|

degassing volume (m3/hr)

|

1500

|

2500

|

4000

|

5000

|

7000

|

|

ultimate vacuum level in extruder chamber (mbar)

|

2

|

2

|

2

|

2

|

2

|

|

final product thickness (mm)

|

0.2-1.8

|

0.2-1.8

|

0.2-1.8

|

0.2-1.8

|

0.2-1.8

|

|

output range (kg/h)

|

80-100

|

160-190

|

300-350

|

360-420

|

560-630

|

COWIN EXTRUSION was founded in 2012 in NANJING, Jiangsu Province. There are more than 50 people working in the company of which 5 engineers,15 people for mechanical processing and management, 20 assembling workers and 5 people for after-sales service.

COWIN EXTRUSION always focuses on R&D of new technology & products, equipment process and manufacturing, and turnkey project of high polymer related processing equipments.

COWIN products are mainly composed:1. twin screw extruders 2. single screw extruders 3. two stage extruders 4. plastic machinery parts 5. plastic granulators 6. ancilliary

Our team has more than 20 years experience in extruder industry. We always focus on innovation during the development and we supply best quality products to customers of both China domestic and overseas.

We follow "win-win" model to support our overseas customers in Taiwan, Viet Nam, Malaysia, Indonesia, Singapore, India, Russia, Turkey, Latvia, French, South Africa, Canada, Mexico, and Brasil etc.

Pre-sales service:

1.Introducing in detail features and application of the products to customer

2.Selecting economical and practical machine & equipment for customer

3.Providing operation data of the related machine & equipment

4.Providing means of trial performance for customer

Sales service:

1.Recommending engineering conditions required for installation of the machine & equipment

2.Communicating in time the manufacturing progress of the machine with user

3.Providing assistance in technical conditions, screw combination and barrel disposition needed for product

After-service:

1.Providing on the spot technical assistance in installation, commissioning and training

2.Filing in detail customer's information

3.Providing long-term maintenance service and spare parts

4.Giving technical support to customer for developing new product

5.Providing free maintenance for a year

Packing:

The whole machine line can be divided into 4-8 wooden boxes. After applying the rust preventive oil, it is placed in a packaging film or a bubble film. Finally, Putting the machine in a wooden box and fix it with steel wire or nails.

Delivery:

10-30 days after confirming order,detail delivery date should be decided according to production season and order quantity.

1. Q: Are you a factory or trading company,How is you factory extrusion experience?

A: We are a factory.20 years experience on supplier in Nanjing city.

2.Q: How long is your machine's guarantee time?

A: 1 year, Main parts is made of high tool steel by special quenching treatment, with high corrosion resistance and wear resistance.

3. Q:What can you provide for after sale service?

A: We provide on the spot technical assistance in installation, commissioning and training if you need.

4. Q:If we have very special request for the production line,could you help me to do the design?

A:We provide experienced mechanical designer customized-design.

5. Q: If we have samples of new products, can you help to analysis and design the machine?

A:Yes, our technical department can help you analyze, design and test the new products you offer.